The Advancement of Round Pipe Polishing Machine Companies A Deep Dive into Innovation and Industry Trends

In the evolving landscape of manufacturing and fabrication, round pipe polishing machines have become indispensable tools for various industries, including construction, automotive, and aerospace. These machines are vital for ensuring that pipes not only meet aesthetic standards but also adhere to strict quality and durability requirements. The companies that specialize in manufacturing these polishing machines play a crucial role in facilitating processes that enhance product longevity and performance.

Understanding Round Pipe Polishing Machines

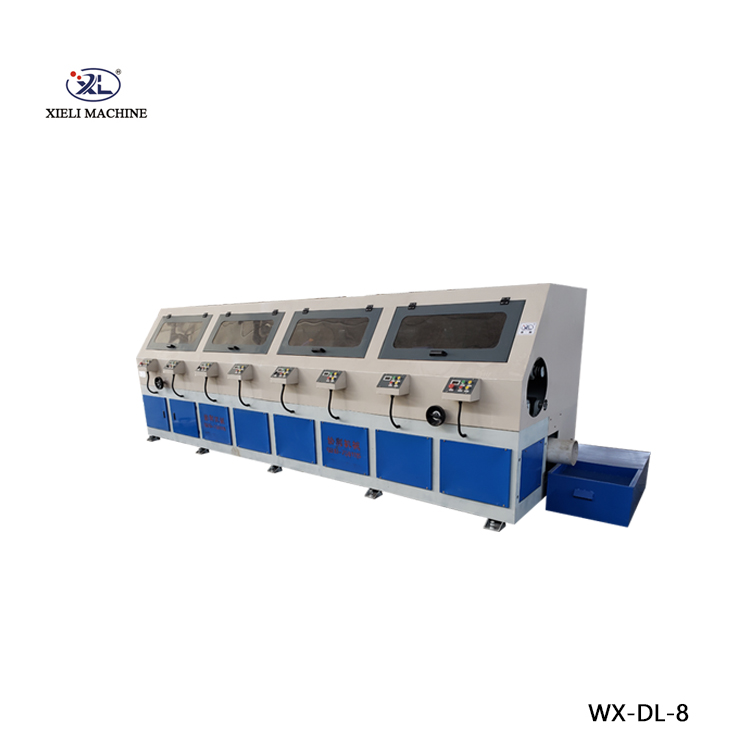

Round pipe polishing machines are designed to achieve a high-quality finish on round pipes. The process involves removing imperfections and applying a smooth finish to enhance the pipe's visual appeal and corrosion resistance. Various types of polishing machines are available, ranging from manual to fully automated systems, each designed to cater to different production volumes and operational complexities.

These machines utilize a combination of abrasives, buffers, and polishing compounds to achieve the desired finish. With advancements in technology, modern polishing machines often incorporate innovative features such as CNC (computer numerical control) for precision and consistency, adjustable speed settings for various materials, and user-friendly interfaces to streamline operations.

The Role of Technology in Machine Development

The rise of Industry 4.0 has significantly influenced the round pipe polishing machine sector. Companies are increasingly adopting automation and IoT (Internet of Things) technologies to enhance efficiency and productivity. Automated polishing machines can work around the clock, minimizing downtime and ensuring uninterrupted production.

Moreover, data analytics tools enable manufacturers to track machine performance in real-time, diagnosing issues before they escalate. Predictive maintenance, a concept driven by big data, allows companies to schedule maintenance activities based on actual use and wear patterns, leading to reduced costs and increased machine lifespan.

Sustainability in Manufacturing Processes

In recent years, sustainability has emerged as a paramount concern across all industries, and the manufacturing sector is no exception. Round pipe polishing machine companies are actively seeking ways to minimize their ecological footprint. This includes developing machines that consume less energy, utilizing eco-friendly polishing compounds, and optimizing waste management practices.

round pipe polishing machine company

Furthermore, manufacturers are increasingly exploring the integration of recyclable materials in their machines’ construction. Sustainable practices not only meet regulatory standards but also align with the growing consumer demand for environmentally responsible products.

Customization and Flexibility

One of the most significant trends within the round pipe polishing machine market is customization. Different sectors require tailored solutions to meet specific finishing standards. To remain competitive, manufacturers are offering bespoke solutions that allow clients to customize their machines' features according to their distinct needs.

This flexibility extends to the machine’s software as well, where clients can choose to integrate specific programming based on pipe specifications. Customization not only enhances the overall efficiency of the polishing process but also leads to better product quality and customer satisfaction.

The Competitive Landscape

The round pipe polishing machine industry is marked by a combination of established companies and emerging players, each vying for market share through innovation and quality. Established companies leverage their experience and reputation to offer robust machines with extensive support services, while new entrants often introduce innovative approaches or niche products that challenge the status quo.

Strategic partnerships and collaborations are increasingly common as companies seek to enhance their product offerings. By partnering with technology firms or material suppliers, round pipe polishing machine companies can ensure they stay ahead of industry trends and meet growing customer demands.

Conclusion

As the demand for high-quality finishes in manufacturing continues to grow, round pipe polishing machine companies are at the forefront of this transformation. With advancements in technology, increased focus on sustainability, customization, and a competitive landscape, these companies are not just manufacturers; they are vital players in the larger narrative of industrial innovation. By investing in modern technologies and sustainable practices, they contribute significantly to the overall efficiency and quality of manufacturing processes, ensuring that they meet the standards of today and the expectations of tomorrow. As we look to the future, it is clear that the evolution of round pipe polishing machines will continue to shape the industries they serve.