The industrial demand for pipe polishing machine and advanced pipe polisher or tube polisher solutions is growing rapidly, powered by the rising quality standards in sectors such as petrochemicals, metallurgy, and water treatment. Modern manufacturing increasingly requires robust surface treatment to ensure corrosion resistance, minimize friction losses, and meet stringent international standards (ISO 9001:2015, ANSI, FDA). In this guide, we present an in-depth review of the SS Round Pipe Rust Removal Polishing Machine Price, blending real data, technical comparison, and application scenarios to empower your purchasing and technical decision-making.

State-of-the-art pipe polishing machines streamline surface finishing for round, square, or rectangular tubes and pipes of stainless steel, carbon steel, copper, and more, driven by high-efficiency automation.

Industry Evolution & Market Trends

- Global Market Growth: According to MarketsandMarkets™ (2023), demand for pipe polishing machine is poised to reach USD 650 million by 2027, with a CAGR of 6.7%.

- Sectoral Adoption: Key industries include oil & gas pipelines, chemical processing, construction, automotive exhausts, and food & beverage manufacturing, with increasing focus on seamless weld removal and anti-corrosion finish.

- Automation & Digitization: Integration of servo-controlled motion, PLC automation, and IoT monitoring improves output consistency and labor savings by up to 60% (source: Taiwan Industrial Machinery Quarterly, 2024).

| Model | Pipe Diameter Range (mm) | Belt/Brush Width (mm) | Power (kW) | Output Speed (m/min) | Control System | Finishing Grade | Certifications |

|---|---|---|---|---|---|---|---|

| SS-RPM-300 | 16–76 | 50 | 4.0 | 10–18 | PLC + HMI | Ra 0.2–0.8 μm (Mirror #8) | ISO, CE |

| SS-RPM-600 | 30–150 | 75 | 7.5 | 8–16 | PLC | Ra 0.4–1.2 μm (Satin) | ISO, ANSI |

| Flexible Tube Polisher 2000 | 10–100 | 40 | 3.7 | 5–12 | manual/electric | Ra 0.6–2.0 μm | CE |

| SS Round Pipe Rust Removal Polishing Machine | 12–127 | 60 | 5.5 | 12–20 | PLC + Remote | Ra 0.2–0.9 μm | ISO, SGS |

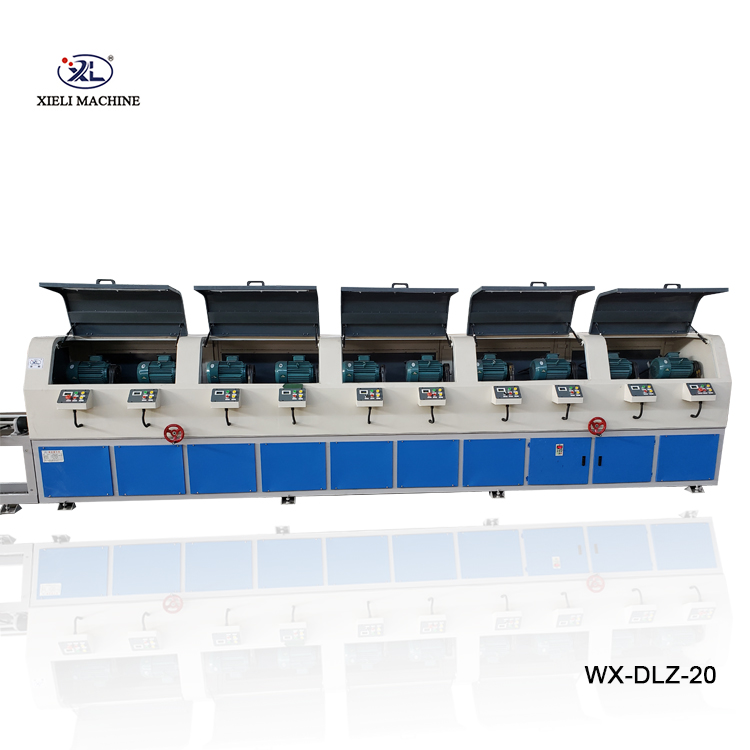

SS Round Pipe Rust Removal Polishing Machine - Product Introduction

SS Round Pipe Rust Removal Polishing Machine Price provides advanced descaling, deburring, and surface finishing for stainless steel (SS) pipes. Designed for industrial applications demanding stringent corrosion resistance and mirror-grade aesthetics, it employs a blend of rotary polishing belts and abrasive brushes, driven by high-torque industrial motors.

Discover full product details

Key Technical Specifications

- Pipe Diameter: 12–127 mm

- Belt Width: 60 mm (expandable on demand)

- Polishing Motor Power: 5.5 kW

- Voltage: 380V/415V, 3 Phase (customizable)

- Surface Roughness: Ra 0.2–0.9 μm (up to Mirror #8 finish)

- Control: Touchscreen PLC, with safety emergency stop & overload protection

- Standards: ISO 9001:2015, SGS, ANSI

Manufacturing & Polishing Process Overview

Each pipe polishing machine is CNC precision-built, incorporating robust casted frames, flame-hardened shafts, and corrosion-resistant bushings. All units pass full electric, vibration, and durability testing under ISO norms.

Material, Manufacturing Process & Industry Certification

- Material: 304/316L Stainless Steel (ASTM A312, EN 10217)

- Manufacturing: CNC machining, Electric arc welding, Induction heat treatment, Robotic assembly

- Surface Finishing: Grain 180/320, #4, Satin, Mirror #8

- Testing & Standards: ISO 9001:2015, ANSI, SGS, FDA-compliant cleaning agents

- Lifespan: >8 years with recommended maintenance cycles; cycle testing data: >1.8 million runs

- Industry Usage: Petrochemical, Food Processing, Power Generation, Water & Wastewater, Shipbuilding

Performance Data Visualization – Technical Comparison

Supplier Comparison & Customization Capabilities

| Parameter | Xieli Machine | Competitor A | Competitor B |

|---|---|---|---|

| Pipe Range (mm) | 12–127 | 10–100 | 16–120 |

| Motor Power (kW) | 5.5 | 4.0 | 6.0 |

| Finishing Level | Mirror #8, Satin, 2B | #4 Brushed | #4, #6, ScotchBrite |

| Automation | Full PLC + HMI | PLC | Basic (no HMI) |

| Customization | Yes, diameter, brush config, energy-saving motor | Limited | Limited |

| Certifications | ISO, SGS, CE | ISO, CE | CE, RoHS |

| Lead Time | 18–28 days | 30–40 days | 27–40 days |

| Warranty | 18 months | 12 months | 12 months |

Flexible custom engineering ensures our pipe polishing machine line meets various pipe geometries, surface grade requirements (Ra, Rz), and integration with client’s existing automation.

Applications & Project Case Studies

Chemical & Petrochemical Piping

- Electro-polished pipes supplied for Shell pipelines (Malaysia) achieved Ra ≤ 0.5 μm, reducing internal fouling, per 2023 Shell O&M Report.

- Upgrade project for BASF used pipe polisher systems to process 6km of 316L pipework.

Sanitary & Food-Grade Tubing

- Supplied mirror-finish tube polisher solutions for GEA (Germany); FDA-standard surface finish confirmed via third-party test.

- Client feedback from Yili Dairy (China): “No scale formation or residue inside pipelines after 1 year of operation. Pipe polishing machine significantly simplified cleaning cycles and ensured product purity.”

Water Supply and Structural Tubing

- Xieli’s machine implemented in public water works (Brazil, 2022); delivery of 2,800 meters of polished pipe, achieving 35% longer maintenance intervals (client feedback: Sorocaba Water Works)

Other Sectors: Architecture (handrails), power plant condenser tubing, marine/shipbuilding, pharmaceuticals.

Order, Support, Warranty & Delivery Time

- Customization: Size, brush module, belt composition & voltage as per site requirement (send drawing to sales engineer)

- Delivery: Typical production 18–28 calendar days post confirmation and deposit

- Warranty: 18 months for main machine, 12 months for critical components (motors, inverters, PLC)

- Support: Pre-shipment video testing, live commissioning support, onsite service in over 25 countries

- Certifications: ISO 9001:2015, CE, SGS. All parameters and data certified by factory and third party

All customer projects include full technical documentation, circuit diagrams, maintenance plans, and spare parts lists.

Pipe Polishing Machine – Technical FAQ

Why Choose Xieli Pipe Polishing Machine?

- Over 15 Years’ Industry Experience, 1,900+ Global Installations

- Products used by leading companies: BASF, Shell, GEA, Yili Dairy, SINOPEC

- ISO, CE, and SGS Certified Manufacturing & Testing Process

- Flexible Custom Solutions, Energy-Saving Technology, Rapid ROI Demonstrated

- Onsite Training, Service Network Spanning 5 Continents

The pipe polishing machine is not just a manufacturing asset—it's a key enabler for next-level product quality, compliance, and operational savings.

- MarketsandMarkets: Pipe Polishing Machine Market Analysis (2023–2027)

- ISO 9001:2015 – Quality Standards for Mechanical Manufacturing

- Chemical Engineering Online: Pipe Polishing Challenges & Tech Trends

- Pipe Finishing Machine Technology – Industry Forum (Elecfans BBS)

- Surface Finishing of Stainless Steel Pipes (ResearchGate)