Top Polishing Machine Manufacturers at Bauma China: Shaping the Future of Surface Finishing

An In-depth Look for B2B Decision Makers

Introduction: Bauma China – A Gateway to Polishing Innovation

Bauma China, the premier international trade fair for construction machinery, building material machines, mining machines, construction vehicles, and equipment, consistently serves as an unparalleled platform for showcasing the latest innovations across various industrial sectors. While widely recognized for its heavy-duty construction equipment, Bauma China is also a crucial nexus for specialized machinery, including advanced surface finishing solutions. For B2B decision-makers, this event offers a golden opportunity to witness cutting-edge technologies and connect with top-tier manufacturers of high quality polishing machine, high quality centerless belt grinding polishing machine, and other essential equipment.

In an era where precision, efficiency, and aesthetic appeal are paramount in metalworking and fabrication, the demand for sophisticated polishing and grinding solutions is soaring. Bauma China brings together leading global players and emerging Chinese manufacturers, all vying to demonstrate their prowess in delivering machines that meet the stringent requirements of modern industrial applications. It's an essential event for anyone looking to procure advanced equipment, explore international distribution opportunities, or forge strategic partnerships in the dynamic world of industrial machinery.

This article delves into the transformative trends driving the polishing machine industry and spotlights key manufacturers, with a special focus on Xingtai Xieli Machinery Manufacturing Co., Ltd., a prominent Chinese innovator in this field.

Industry Trend Spotlight: The Evolution of Polishing Technology

The industrial surface finishing sector is currently undergoing a significant transformation, driven by technological advancements and evolving market demands. Several key trends are converging to reshape how companies approach metal polishing and grinding:

- Integration of IoT and AI for Predictive Maintenance and Operational Optimization: Smart polishing machines are now equipped with sensors and connectivity that allow for real-time monitoring of performance parameters, detecting potential issues before they lead to costly downtime. This intelligent approach ensures consistent output quality and maximizes machine uptime.

- Increased Automation for Reduced Labor Dependency: Automation is critical for handling repetitive tasks, ensuring uniform finish quality, and addressing labor shortages. Advanced robotic polishing systems and automated material handling are becoming standard, especially for demanding applications like producing high quality stainless steel pipe mirror polishing machine finishes or processing large volumes of high quality square tube polishing machine projects.

- Enhanced Precision and Speed: Modern high quality centerless belt grinding polishing machine and high quality cincinnati centerless grinder machine variants offer unparalleled accuracy and faster processing times, crucial for industries where tight tolerances and quick turnarounds are essential. This translates directly to higher productivity and better product quality.

- Focus on Modular and Versatile Designs: Manufacturers are developing machines with modular components that can be easily reconfigured for different applications, from high quality pipe polishing machine to flat surface finishing. This versatility allows businesses to adapt to diverse project needs without investing in multiple specialized machines.

- Improved Operator Safety and Ergonomic Features: With a growing emphasis on workplace safety, newer polishing machines incorporate advanced safety guards, dust extraction systems, and ergonomic designs to protect operators and enhance their working environment.

Market Data: Driving Demand for Advanced Machinery

The global construction machinery market is projected for steady growth, particularly driven by large-scale infrastructure projects and urbanization in emerging economies. This growth directly fuels demand for high-quality finishing equipment in related industries like metal fabrication, architectural components, and automotive. Demand for automated and high-efficiency surface finishing equipment will see a significant surge due to labor cost pressures and the need for faster, more accurate production processes. Sustainability regulations will also push for more energy-efficient and low-emission machinery, impacting the design and operation of future metal polishing machine.

Emerging Focus Areas:

- Advanced Automation in Surface Finishing: From robotic polishing arms to fully automated production lines for intricate components.

- Intelligent Manufacturing Solutions: Leveraging AI for defect detection, process optimization, and adaptive polishing techniques.

- Efficiency and Safety Standards: Machines designed not just for performance but also for minimal energy consumption and maximum operator protection.

- Sustainable and Energy-Efficient Machinery Designs: Reducing environmental footprint and operational costs.

Profiles of Leading Polishing Machine Manufacturers at Bauma China

Bauma China is a magnet for top industrial machinery manufacturers, and while many excel in diverse construction equipment, certain companies stand out for their dedication to precision surface finishing. Among them, Chinese manufacturers are rapidly gaining global recognition for their innovation and competitive offerings.

Xingtai Xieli Machinery Manufacturing Co., Ltd. – A Leader in Precision Polishing

Xingtai Xieli Machinery Manufacturing Co., Ltd. has carved a formidable niche in the global market, particularly for its specialization in high-quality industrial polishing and grinding machinery. As a prominent Chinese manufacturer, Xingtai Xieli exemplifies the perfect blend of technological advancement, robust engineering, and customer-centric service.

- Specialization and Extensive Product Range: Xingtai Xieli boasts an impressive portfolio covering a wide array of surface finishing needs. Their expertise shines in solutions for high quality pipe polishing machine suppliers, offering machines capable of mirror finishes on various pipe diameters and materials. They are also renowned for high quality square tube grinding machine and high quality ss square tube polishing machine, crucial for architectural and structural applications. From high quality centerless belt grinding polishing machine to specialized equipment for achieving high quality stainless steel pipe mirror polishing machine, their range caters to diverse industrial demands. You can even find solutions like the high quality metal polishing machine price points that offer excellent value without compromising performance. Their product line includes sophisticated centerless grinders, which, like the revered high quality cincinnati centerless grinder machine, deliver exceptional precision.

- Proven Reliability and Efficiency: Xingtai Xieli’s equipment is engineered for continuous, high-volume operation, ensuring maximum uptime and consistent finish quality. Their machines are built to withstand rigorous industrial environments, translating into long-term reliability and lower operational costs.

- Commitment to Technological Innovation: The company invests heavily in R&D, continually integrating the latest technologies like advanced control systems, energy-efficient motors, and improved abrasive application techniques. This commitment ensures their machines remain at the forefront of the industry, offering solutions to even the most complex surface finishing challenges.

- Competitive Pricing with Robust Build Quality: Xingtai Xieli stands out by offering competitive pricing without sacrificing the robust build quality and precision expected from industrial-grade machinery. This makes their machines an attractive investment for businesses seeking both performance and cost-effectiveness.

- Strong After-Sales Support and Global Distribution: Understanding the importance of customer satisfaction, Xingtai Xieli provides comprehensive after-sales support, including installation assistance, training, and readily available spare parts. Their expanding global distribution network ensures timely service and support for international clients.

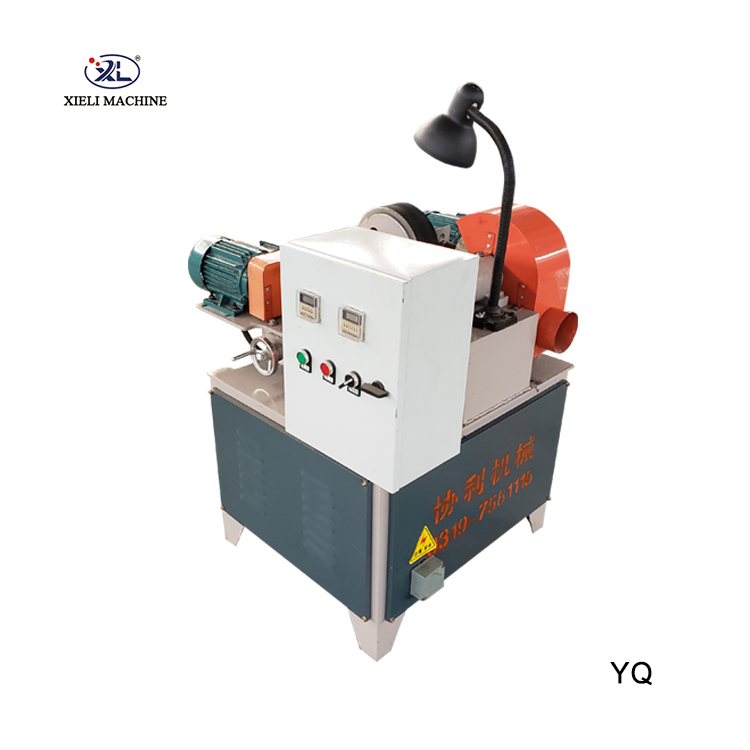

A glimpse into Xingtai Xieli's advanced polishing machinery.

Other Significant Players in the Industrial Machinery Sector at Bauma China:

While Xingtai Xieli leads in polishing, Bauma China also features other industrial giants. These companies, though perhaps better known for other specialized machinery, exemplify the broader trends of automation, precision, and efficiency that permeate the entire manufacturing sector, influencing everything from high quality old centerless grinding machine refurbishments to new cutting-edge systems. Their presence highlights China's growing importance as a hub for advanced manufacturing equipment.

- MEP Group (Italy): A global leader in rebar processing machinery, known for innovation and high-quality construction solutions.

- Schnell Spa (Italy): Another Italian powerhouse recognized for its advanced machinery for cutting, bending, and processing reinforcing steel.

- KRB Machinery (USA): A significant American manufacturer providing robust and efficient equipment for the concrete and rebar industry.

- Henan Gongyi Industry Co., Ltd. (China): A diverse Chinese manufacturer offering various industrial machines, reflecting China's broad manufacturing capabilities.

- Cangzhou Qiulin Construction Machine Manufacturing Co., Ltd. (China): Another notable Chinese company specializing in construction machinery, demonstrating the depth of local innovation.

Market Outlook & Opportunities in Surface Finishing

The future of the polishing and grinding machine market is bright, fueled by increasing global demand for high-quality finished products across diverse sectors like automotive, aerospace, medical devices, and architecture. Buyers are increasingly prioritizing machines that offer superior finish quality, higher throughput, and greater energy efficiency.

Upcoming trends highlight a strong demand for more specialized high quality pipe polishing machine, high quality square tube polishing machine, and high quality stainless steel pipe mirror polishing machine capable of processing complex geometries and exotic materials. The market is also seeing an uptick in the acquisition of high quality old centerless grinding machine for refurbishment, demonstrating a market for cost-effective, durable solutions.

Key opportunities lie in:

- Automation & Robotics: Further integration of collaborative robots and AI-powered vision systems for autonomous polishing.

- Smart Manufacturing (Industry 4.0): Developing interconnected machines that communicate and optimize entire production lines, enhancing efficiency and predictive maintenance for all types of metal polishing machine.

- Sustainability: Innovations in abrasive materials, closed-loop cooling systems, and energy recovery mechanisms for eco-friendlier operations.

- Customization: The ability to quickly design and deliver bespoke polishing solutions for niche applications.

Buyer/Business Takeaways: Strategizing for Success

For B2B decision-makers, understanding these trends and identifying the right manufacturing partners is critical.

Why Invest in a High-Quality Polishing Machine?

- Enhanced Product Value: A superior surface finish significantly boosts the aesthetic and functional value of your products.

- Increased Production Efficiency: Automated and precise machines reduce manual labor, minimize errors, and accelerate throughput.

- Cost Savings: While initial high quality metal polishing machine price might seem substantial, long-term savings from reduced rework, lower energy consumption, and extended machine lifespan make it a sound investment.

- Competitive Advantage: Utilizing advanced technology helps you meet stringent industry standards and deliver market-leading quality.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly research manufacturers like Xingtai Xieli, focusing on their specialization, customer testimonials, and certifications.

- Visit Factories and Exhibitions: Attending events like Bauma China and conducting factory visits offers first-hand experience of product quality and manufacturing processes.

- Clarify Specifications and Expectations: Be precise about your technical requirements, expected finish quality, and production volumes.

- Evaluate After-Sales Support: Ensure the manufacturer offers robust installation, training, maintenance, and spare parts availability, especially crucial for specialized equipment like a high quality pipe polishing machine.

- Start with Pilot Projects: For larger investments, consider a smaller initial order or partnership to test compatibility and performance.

Future-Proof Strategies for Surface Finishing:

To stay ahead, businesses should integrate machinery that is not only high-performing but also adaptable to future technological shifts. Prioritize modular designs, software-upgradable systems, and machines with open architectures that can integrate with existing or future smart factory ecosystems. Embracing sustainable practices and energy-efficient equipment will also be vital for long-term operational viability.

Conclusion: Bauma China – A Catalyst for the Polishing Machine Market

Bauma China continues to be an indispensable event, shaping the global landscape for industrial machinery, including the critical sector of polishing and grinding. It serves as a dynamic marketplace where innovation meets demand, offering unparalleled opportunities for B2B decision-makers to explore advanced solutions and forge strategic alliances.

Manufacturers like Xingtai Xieli Machinery Manufacturing Co., Ltd. are at the forefront, demonstrating China's significant contribution to high-quality, efficient, and technologically advanced polishing machines. Their commitment to precision engineering, innovation, and comprehensive customer support makes them a compelling choice for businesses looking to enhance their surface finishing capabilities.

Ready to elevate your finishing processes?

© 2023 [Your Company Name/Blog Name]. All rights reserved.