Industry Trends in Precision Surface Finishing

The demand for superior surface integrity and dimensional accuracy in industrial components has never been higher. From the exacting requirements of aerospace and medical device manufacturing to the rigorous demands of hydraulic systems and energy infrastructure, the performance and longevity of critical parts are directly correlated with their surface finish. This has driven significant innovation in precision machining and finishing technologies. The global market for surface finishing equipment is projected to grow steadily, fueled by advancements in automation, material science, and stringent quality control standards.

Key industry trends include the increasing adoption of automated polishing systems, the development of more efficient and environmentally friendly abrasive materials, and the integration of advanced metrology for real-time quality assurance. Manufacturers are increasingly seeking solutions that not only enhance product performance but also reduce operational costs and environmental impact. This paradigm shift underscores the critical role of specialized machinery like the cylinder polishing machine, which is at the forefront of delivering high-precision, eco-conscious finishing for cylindrical components. Related technologies, such as the tube polishing machine, also demonstrate this trend, focusing on efficient and high-quality finishing of tubular workpieces. The focus is now on systems that offer versatility, repeatability, and superior surface quality with minimal environmental footprint.

Detailed Process Flow of a Cylinder Polishing Machine

The operation of a high-performance cylinder polishing machine involves a sophisticated multi-stage process designed to achieve optimal surface finish and dimensional accuracy. Understanding this process is crucial for appreciating the technical prowess embedded in these advanced systems.

Machine Manufacturing and Materials

The construction of the polishing machine itself utilizes robust materials and precision manufacturing processes. The machine frame typically employs high-grade cast iron or heavy-gauge welded steel, stress-relieved to ensure long-term dimensional stability and vibration damping during operation. Critical components, such as guide rails, spindles, and gearboxes, are often made from hardened alloy steels, precision-ground, and then subjected to advanced surface treatments like nitriding or chrome plating to enhance wear resistance. CNC machining is extensively used for manufacturing these components, ensuring sub-micron level tolerances for smooth and accurate machine movement.

Polishing Process Steps (Schematic)

Automated or manual loading onto precisely aligned fixtures. Ensuring concentricity and secure clamping.

Initial material removal using coarse abrasives (e.g., Alumina, Silicon Carbide). Eliminating major surface defects and machining marks.

Transition to finer abrasives. Refining the surface texture and preparing for the final finish.

Utilizing ultra-fine abrasives or specialized buffing compounds. Achieving specified Ra values and mirror-like finishes.

Removal of residues, followed by comprehensive surface roughness (Ra, Rz), roundness, and visual inspections using advanced metrology tools.

Testing Standards and Service Life

Our polishing machines adhere to stringent international testing standards, including ISO 9001 for quality management systems and ANSI B11.1 for machine tool safety. Output quality is consistently verified against ISO 4287 (Surface Texture Parameters) and JIS B0601 standards. The robust design and high-quality components ensure an extended service life for our machines, typically exceeding 15-20 years with proper maintenance, significantly reducing total cost of ownership (TCO).

Target Industries and Advantages

The precision and efficiency of our cylinder polishing machine make it indispensable across diverse heavy industries:

- Petrochemical: Polishing hydraulic cylinders for oil and gas extraction equipment, pump shafts, and pipeline components. Advantages include enhanced corrosion resistance against aggressive media and reduced friction for improved energy efficiency in hydraulic systems, leading to longer seal life.

- Metallurgy: Finishing steel rolls, billets, and large-diameter pipes. Ensures consistent surface quality for subsequent processing or final application, reducing defects and improving material integrity.

- Water Supply & Drainage: Polishing components for large valves, pumps, and water treatment equipment. Critical for preventing material adhesion and improving resistance to environmental degradation, extending operational lifespan.

- Automotive: Crankshafts, camshafts, and shock absorber rods benefit from super-fine finishes, leading to reduced friction, improved fuel efficiency, and extended component life.

- Heavy Machinery: Polishing large piston rods, machine columns, and other high-load bearing surfaces to improve wear resistance and operational reliability.

Precision engineering within a cylinder polishing machine.

Technical Specifications and Performance Parameters

The "Environmentally friendly new cylinder polishing machine" is engineered for superior performance, offering a blend of precision, efficiency, and sustainability. Below are the key technical specifications that define its capabilities.

| Parameter | Specification | Description/Benefit |

|---|---|---|

| Workpiece Diameter Range | Ø20mm - Ø500mm (0.8" - 20") | Versatile for a wide array of cylindrical components, including precision hydraulic rods and large industrial tubes. |

| Workpiece Length | Up to 6000mm (236") | Accommodates extended shafts and pipelines, reducing need for multiple setups. |

| Achievable Surface Roughness (Ra) | 0.05µm - 0.8µm (2µin - 32µin) | Exceeds industry standards for critical applications, minimizing friction and wear. |

| Main Spindle Motor Power | 11 kW (15 HP) - 37 kW (50 HP) | Robust power for consistent material removal and high throughput. |

| Abrasive Belt Width | 50mm - 150mm (2" - 6") | Flexibility in selecting abrasive types and widths for various finishes and materials. |

| Control System | Siemens/Fanuc PLC with HMI | Intuitive operation, precise process control, and easy integration into factory automation systems. |

| Coolant System Capacity | 200L - 1000L with Filtration | Efficient heat dissipation, extended abrasive life, and superior surface finish through continuous coolant quality. |

| Machine Weight | 3,000kg - 12,000kg (6,600 lbs - 26,500 lbs) | Heavy-duty construction for stability, minimal vibration, and long-term precision. |

| Accuracy & Repeatability | ±5µm (0.0002") | Ensures consistent quality across batches, critical for high-volume precision manufacturing. |

User interface of a modern cylinder polishing machine.

Application Scenarios and Target Industries

The versatility and precision of a modern cylinder polishing machine extend its application across a broad spectrum of industries where surface quality is paramount. These machines are not merely tools for aesthetics but are vital for enhancing the functional performance, durability, and reliability of cylindrical components.

-

Hydraulic & Pneumatic Systems

In hydraulic cylinders, piston rods, and valve stems, surface finish directly impacts seal life, friction, and fluid leakage. Our cylinder polishing machine achieves micro-level smoothness, drastically reducing wear on seals and extending the operational life of hydraulic components, which is critical in heavy machinery, construction, and agricultural equipment. This also translates to improved energy efficiency by minimizing frictional losses.

-

Automotive & Aerospace Industry

For engine components like crankshafts, camshafts, and shock absorber shafts, precision polishing reduces friction, improves lubrication, and enhances fatigue resistance. In aerospace, components such as landing gear cylinders and control rods demand exceptionally high surface integrity to withstand extreme operational conditions and ensure flight safety. The ability to achieve ultra-fine finishes with high repeatability is a key advantage.

-

Power Generation & Energy Sector

Turbine shafts, generator rotors, and large valve components in power plants and renewable energy systems require robust and precise surface finishing. Enhanced surface hardness and corrosion resistance provided by a polished finish contribute to the longevity and efficient operation of these critical assets, especially in challenging environments.

-

Medical Device Manufacturing

For implants, surgical instruments, and pharmaceutical processing equipment, biocompatibility and sterility are paramount. A perfectly polished surface minimizes potential sites for bacterial adhesion and facilitates thorough cleaning and sterilization, meeting strict regulatory standards like FDA. The related tube polishing machine is also crucial here for instruments and cannulas.

-

General Manufacturing & Tooling

From chrome-plated rods to precision tooling, the machine ensures optimal surface quality for extended tool life, improved product appearance, and reliable performance across various manufacturing processes.

Technical Advantages and Environmental Benefits

The "Environmentally friendly new cylinder polishing machine" represents a leap forward in surface finishing technology, integrating advanced engineering with sustainable practices. Its technical advantages translate directly into significant operational and environmental benefits for our clients.

-

Unmatched Precision and Surface Integrity

Utilizing state-of-the-art abrasive systems and finely tuned control algorithms, our machines achieve surface roughness values (Ra) down to 0.05µm. This level of precision is critical for reducing friction, extending component life, and ensuring optimal performance in high-stress applications. The controlled material removal process preserves the component's structural integrity, preventing sub-surface damage.

-

Advanced Automation and Repeatability

Integrated with Siemens or Fanuc PLC systems and intuitive HMI, the machine offers fully automated polishing cycles. This not only significantly reduces labor costs but also guarantees unparalleled repeatability across batches, minimizing human error and ensuring consistent, high-quality output every time. Features like automatic tool compensation and workpiece measurement further enhance operational efficiency.

-

Superior Corrosion and Wear Resistance

A highly polished surface fundamentally alters the material's interaction with its environment. By removing micro-irregularities, it significantly reduces the surface area exposed to corrosive agents and diminishes sites where wear can initiate. This translates to substantially improved corrosion resistance and extended wear life for components operating in harsh or abrasive conditions, especially relevant for industries like petrochemical and marine.

-

Energy Efficiency and Environmental Stewardship

Our commitment to environmental responsibility is reflected in the design of this "Environmentally friendly new cylinder polishing machine". It features:

- Optimized Power Consumption: High-efficiency motors and intelligent power management systems reduce energy consumption by up to 20% compared to previous generations.

- Advanced Coolant Filtration: Multi-stage filtration systems extend coolant life and reduce the need for disposal, minimizing chemical waste.

- Reduced Abrasive Consumption: Precision control and optimized contact pressure prolong abrasive belt life, decreasing consumable waste.

- Low Noise Operation: Engineered for quiet performance, contributing to a healthier work environment.

-

Reduced Operational Costs

Beyond energy savings, the machine’s efficiency, longevity, and reduced need for manual intervention translate into lower overall operational expenditures, offering a superior return on investment (ROI).

Vendor Comparison and Market Positioning

In a competitive market for precision finishing equipment, discerning buyers evaluate vendors not just on product specifications, but on a holistic offering of technology, support, and long-term value. Our "Environmentally friendly new cylinder polishing machine" stands out through a combination of cutting-edge features and a commitment to customer success.

| Feature/Criterion | Our Machine (Xielizz) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Automation Level | Full PLC control, HMI, optional robotic integration for loading/unloading. | Semi-automatic with manual setups; basic digital controls. | Automated core processes, limited HMI. |

| Surface Finish Achievable (Ra) | Down to 0.05µm, highly consistent. | 0.1µm - 0.4µm, moderate consistency. | 0.08µm - 0.2µm, good consistency. |

| Energy Efficiency | High (20% reduction vs. previous gen), optimized motors. | Standard industrial efficiency. | Improved, but not class-leading. |

| Customization Options | Extensive customization for dimensions, material, integration. | Limited standard options only. | Moderate customization within predefined modules. |

| After-Sales Support | Global network, 24/7 remote support, on-site service, training. | Regional support, limited remote assistance. | Good local support, outsourced global service. |

| Certifications | ISO 9001, CE, specific industry standards met. | Basic CE compliance. | ISO 9001. |

Our Unique Market Proposition

Our brand is synonymous with precision, reliability, and innovation in surface finishing. We have been serving the B2B sector for over two decades, building a reputation for delivering robust and technologically advanced solutions. Our "Environmentally friendly new cylinder polishing machine" is a testament to this legacy, offering:

- Superior Performance: Consistently achieving ultra-low Ra values and exceptional dimensional accuracy.

- Sustainable Operations: Leading the industry in energy efficiency and waste reduction.

- Comprehensive Customization: Engineering solutions precisely tailored to unique production requirements.

- Unwavering Support: A global service network ensuring minimal downtime and maximum productivity.

Our certifications (ISO 9001, CE, etc.) and long-standing partnerships with industry leaders (e.g., Siemens, SKF, ABB) underscore our commitment to quality and innovation.

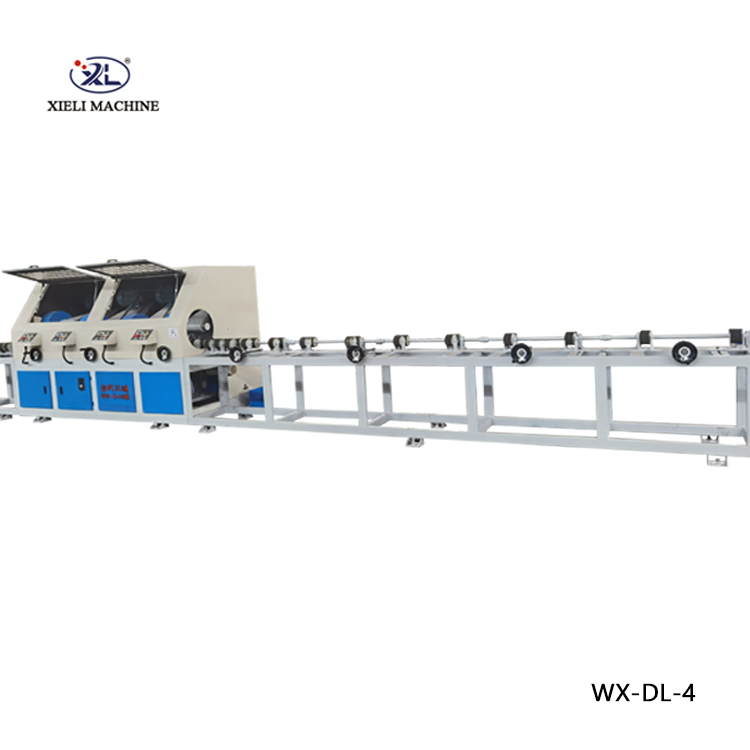

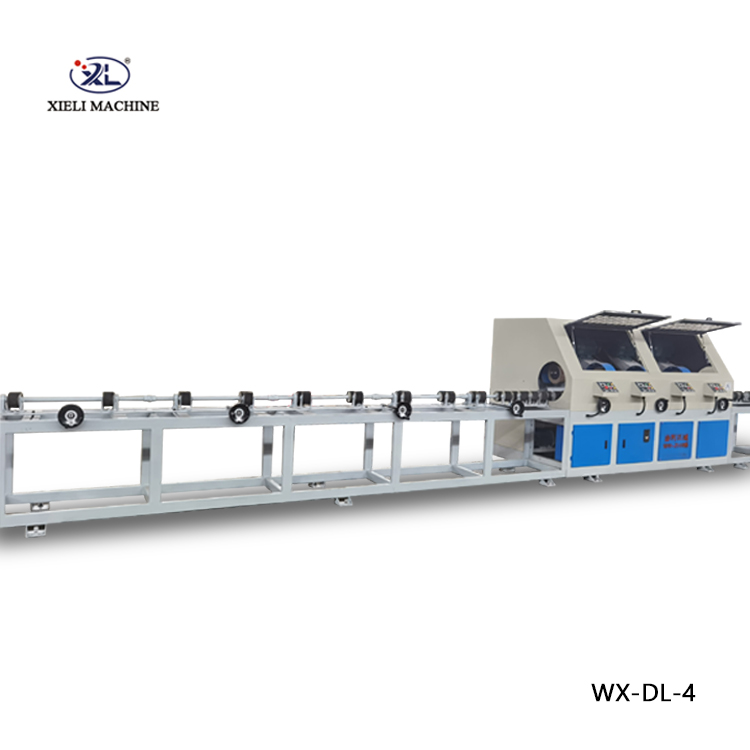

A robust cylinder polishing machine in operation.

Customized Solutions

Recognizing that no two manufacturing processes are identical, we specialize in providing bespoke cylinder polishing machine solutions. Our engineering team collaborates closely with clients to understand specific operational challenges, material characteristics, desired surface finishes, and integration requirements. This consultative approach ensures that each machine is perfectly aligned with the client's production ecosystem, maximizing efficiency and ROI.

Tailored Modifications and Integrations:

- Workpiece Handling: Custom-designed loading/unloading systems, including robotic automation, conveyor integration, and specialized fixturing for unique part geometries (e.g., tapered, asymmetrical).

- Abrasive System Adaptation: Development of multi-head polishing units or specific abrasive sequences to achieve complex surface finishes on challenging materials (e.g., hardened steels, ceramics, exotic alloys).

- Process Parameter Optimization: Fine-tuning of spindle speeds, oscillation rates, abrasive contact pressure, and coolant flow to meet precise Ra, Rz, or Rpk/Rvk requirements.

- Environmental Controls: Integration of advanced mist collectors, improved coolant recycling systems, or specialized filtration for specific waste streams, enhancing the "environmentally friendly" aspect.

- Data Acquisition & SPC: Implementation of real-time monitoring and Statistical Process Control (SPC) modules for comprehensive data logging, quality trend analysis, and predictive maintenance.

- Safety Features: Bespoke safety interlocks, guarding, and emergency stop systems designed to comply with local and international safety regulations specific to the client's operating environment.

Our engineering team is adept at navigating the complexities of integrating new machinery into existing production lines, ensuring seamless data flow and operational synergy.

Application Case Studies

The tangible benefits of our cylinder polishing machine are best illustrated through real-world applications. These case studies highlight how our customized solutions address critical industry challenges, delivering quantifiable improvements in product quality, efficiency, and cost-effectiveness.

Case Study 1: Hydraulic Rod Finishing for Heavy Equipment Manufacturer

- Client: Global leader in construction and mining machinery.

- Challenge: Inconsistent surface finish on large hydraulic piston rods (Ø150mm x 4000mm), leading to premature seal failure and high warranty claims. Manual polishing was labor-intensive, slow, and non-repeatable. Desired Ra value of

- Solution: We provided a customized "Environmentally friendly new cylinder polishing machine" with a specialized heavy-duty clamping system and a multi-head polishing configuration. The machine integrated an automated loading/unloading system and real-time surface roughness monitoring.

-

Results:

- Achieved consistent Ra of 0.08µm across all rods.

- Reduced seal failure rate by 45% in field tests.

- Increased production throughput by 30% and reduced labor costs by 70%.

- Client feedback highlighted significant improvement in product reliability and customer satisfaction.

Case Study 2: Medical Grade Tube Polishing

- Client: Manufacturer of stainless steel surgical instruments and cannulas.

- Challenge: Achieving a sterile, mirror-like finish (Ra

- Solution: We provided a specialized tube polishing machine, a variant of our cylinder polishing technology, with fine-abrasive polishing heads and a dedicated closed-loop coolant system to prevent contamination. The machine featured precision pressure control for delicate workpieces.

-

Results:

- Consistently achieved Ra values below 0.07µm, meeting all regulatory requirements.

- Eliminated micro-scratches and surface defects, leading to a 20% reduction in rejection rates.

- Improved overall product aesthetics and sterilizability, enhancing market appeal.

- The client reported increased confidence in meeting audits and expanding product lines.

Finished components from a cylinder polishing machine.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building long-term partnerships in the B2B sector hinges on trust and transparency. We are committed to providing comprehensive support throughout the lifecycle of our "Environmentally friendly new cylinder polishing machine" and associated solutions.

Frequently Asked Questions (FAQ)

A: Our cylinder polishing machine is highly versatile and can effectively polish a wide range of materials, including various grades of steel (carbon, stainless, tool steel), chrome-plated surfaces, non-ferrous metals (aluminum, brass, copper), and some exotic alloys. Specific abrasive configurations are recommended for optimal results on different materials.

A: The machine features adjustable workpiece supports and polishing heads, allowing it to accommodate a wide range of diameters and lengths as specified in the technical parameters (e.g., Ø20mm - Ø500mm, up to 6000mm length). Our customized solutions can further extend these ranges based on specific client requirements.

A: Abrasive belt lifespan varies significantly based on workpiece material, desired finish, and operational parameters. Our machines are designed for quick and easy abrasive belt replacement, typically taking only a few minutes. We also offer guidance on optimal abrasive selection to maximize efficiency and belt life.

A: While the HMI is intuitive, we provide comprehensive on-site training for operators and maintenance personnel. This ensures that your team can fully utilize the machine's capabilities, perform routine maintenance, and troubleshoot minor issues effectively.

Lead Time and Fulfillment

Standard "Environmentally friendly new cylinder polishing machine" models typically have a lead time of 10-14 weeks from order confirmation to shipment. For highly customized solutions, the lead time may extend to 16-20 weeks, depending on the complexity of engineering and component sourcing. We maintain transparent communication throughout the manufacturing process, providing regular updates on project milestones. Delivery and installation timelines are then coordinated based on client readiness and logistical considerations.

Warranty Commitments

All our cylinder polishing machine products come with a standard 12-month warranty covering parts and labor against manufacturing defects. Extended warranty options and comprehensive service contracts are available to provide additional peace of mind and maximize machine uptime. Our warranty is backed by our global service network, ensuring prompt and efficient resolution of any issues.

Customer Support and After-Sales Service

Our commitment extends well beyond the point of sale. We offer:

- 24/7 Technical Support: Remote diagnostic and troubleshooting assistance via phone, email, and secure online portals.

- On-Site Service: A global network of certified technicians available for installation, commissioning, maintenance, and complex repairs.

- Spare Parts Availability: Guaranteed access to genuine spare parts with efficient logistics to minimize downtime.

- Preventative Maintenance Programs: Tailored service plans designed to optimize machine performance and extend operational life.

- Training and Documentation: Comprehensive operational manuals and advanced training modules to empower your team.

Dedicated customer support for our cylinder polishing machine.

Authoritative References

- ISO 4287: Geometrical product specifications (GPS) -- Surface texture: Profile method -- Terms, definitions and parameters. International Organization for Standardization.

- Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology (7th ed.). Pearson. (Specifically, chapters on Abrasive Machining and Surface Finishing).

- ASM Handbook, Volume 5: Surface Engineering. (1994). ASM International.

- ASTM B499-09: Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals. ASTM International.

- The Guide to Environmental Regulations. (2023). Environmental Protection Agency (EPA).