Navigating Excellence: Top Polishing Machine Manufacturers at Bauma China

Bauma China stands as a colossal stage for innovation, a biennial spectacle where the pulse of global construction and industrial machinery can be felt. For B2B decision-makers and industry professionals, it’s not just an exhibition; it's a strategic hub for discovering the cutting edge, forging invaluable partnerships, and securing distribution agreements. This year, the spotlight shines brightly on advancements in metal processing, particularly in the domain of polishing machines and centerless grinding technology – essential components for achieving precision and surface finish across countless industrial applications.

The event provides an unparalleled opportunity to witness firsthand the latest innovations in machinery designed for flawless surface finishing, from robust industrial metal polishing machines to sophisticated bar centerless grinders. For companies seeking to enhance product quality, improve operational efficiency, and expand their market reach, Bauma China is the definitive platform to connect with leading manufacturers, explore new technologies, and discuss potential international distributor and partnership opportunities. The value proposition for the polishing machine industry here is immense, offering insights into future trends and a direct line to top-tier suppliers.

Industry Trend Spotlight: Precision, Automation, and Intelligence

The landscape of industrial metal finishing is undergoing a transformative shift, driven by a global demand for higher precision, greater efficiency, and reduced operational costs. Several key trends are converging to redefine what’s possible in the polishing machine sector:

- Integration of IoT and AI: The future is smart. Machines equipped with Internet of Things (IoT) sensors and Artificial Intelligence (AI) algorithms are becoming standard. This allows for predictive maintenance, where potential issues are identified before they lead to costly downtime, and operational optimization, ensuring peak performance for machines like the bar centerless grinder or an internal centerless grinding machine.

- Increased Automation for Reduced Labor Dependency: As labor costs rise and skilled labor becomes scarcer, highly automated industrial metal polishing machines are gaining traction. This not only mitigates labor challenges but also ensures consistent quality and higher throughput.

- Enhanced Precision and Speed: Modern finishing processes demand unparalleled accuracy and faster cycle times. Innovators are constantly pushing the boundaries to deliver machines that can achieve tighter tolerances and superior surface finishes at higher speeds, crucial for applications ranging from automotive components to precision rods, often achieved through advanced engine centerless grinder machine for sale models.

- Focus on Modular and Versatile Designs: Manufacturers are recognizing the need for adaptability. Polishing and grinding machines with modular designs allow for customization and easy integration into diverse production lines, catering to specific project needs without extensive retooling.

- Improved Operator Safety and Ergonomic Features: Safety is paramount. Next-generation machines incorporate advanced safety protocols and ergonomic designs, reducing operator fatigue and minimizing workplace hazards.

The market data underscores this momentum: The global construction machinery market, which encompasses many applications for polishing and grinding, is projected for steady growth, particularly driven by large-scale infrastructure projects and urbanization in emerging economies. Within this broader context, demand for automated and high-efficiency metal finishing equipment, including specialized units like the industrial metal polishing machine and various centerless grinder models, will see a significant surge. This is primarily due to intensifying labor cost pressures and the imperative for faster, more accurate manufacturing and construction processes. Furthermore, sustainability regulations are increasingly pushing for more energy-efficient and low-emission machinery, impacting design and material choices.

Emerging focus areas include advanced automation in metal polishing and grinding, intelligent manufacturing solutions that leverage data, stringent efficiency and safety standards, and sustainable, energy-efficient machinery designs that reduce environmental impact and operational costs.

Profiles of Leading Manufacturers Driving Innovation

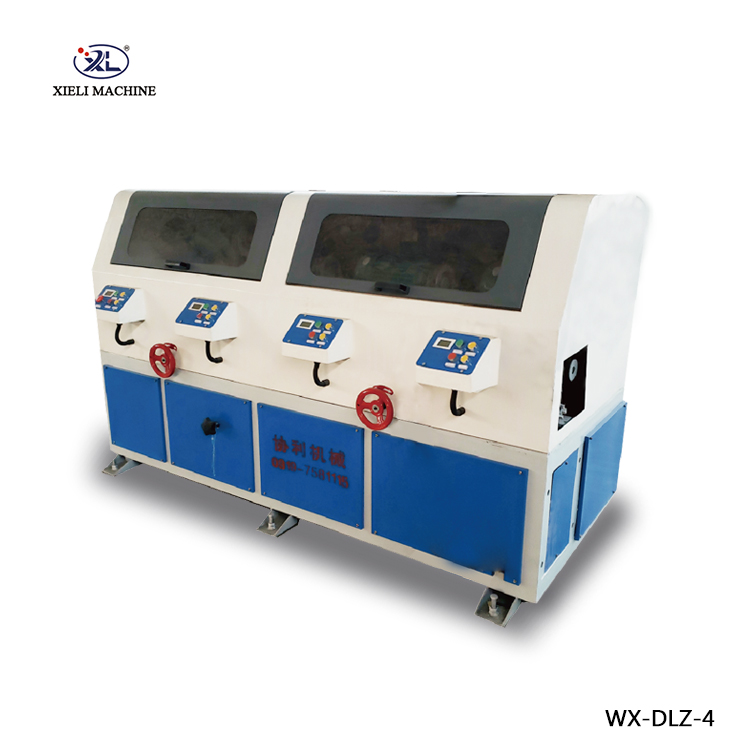

Xingtai Xieli Machinery Manufacturing Co., Ltd.

A formidable player emerging from China, Xingtai Xieli Machinery Manufacturing Co., Ltd. stands out for its deep specialization and extensive product range in high-quality metal polishing and grinding machinery. At Bauma China, they are showcasing their commitment to precision and performance, offering solutions that cater to a wide array of industrial demands.

Xingtai Xieli has earned a reputation for the proven reliability and efficiency of its equipment. Their offerings include robust industrial metal polishing machines, versatile bar centerless grinders, and advanced solutions for various metal finishing applications. Whether you're seeking an engine centerless grinder machine for sale or a specialized unit for internal grinding, Xingtai Xieli's product lineup is designed for superior surface quality and dimensional accuracy. Their commitment to technological innovation is evident in their continuous improvement cycles, incorporating feedback and market trends to deliver cutting-edge solutions.

What truly sets Xingtai Xieli apart is their commitment to providing competitive pricing without compromising on robust build quality. This balance makes their machines an attractive investment for businesses globally. Complementing their strong product line, they offer strong after-sales support and are actively expanding their global distribution capabilities, seeking new partners to bring their reliable finishing solutions, including specialized units often featuring elements reminiscent of filmatic for centerless grinder machine technology, to a wider international audience. For specific applications requiring high precision like an internal centerless grinding machine, Xingtai Xieli delivers advanced, cost-effective options.

Other Noteworthy Industrial Machinery Innovators

While Xingtai Xieli focuses intensely on the polishing and grinding sector, the broader industrial machinery landscape at Bauma China also features global leaders whose innovative spirit influences all aspects of manufacturing, including high-precision finishing. These companies set benchmarks for automation, durability, and technological advancement:

- MEP Group (Italy): Renowned globally for advanced machinery, MEP Group's engineering excellence and focus on automation in industrial processing serve as a high standard for all machinery types, including those requiring precision finishing.

- Schnell Spa (Italy): Another Italian powerhouse, Schnell is synonymous with high-tech, robust industrial solutions. Their emphasis on innovation and system integration provides valuable insights into future machinery trends.

- KRB Machinery (USA): A leading name in specialized industrial machinery, KRB's dedication to performance and durability offers a strong point of reference for quality and long-term investment.

- Henan Gongyi Industry Co., Ltd. (China): A significant domestic player, Henan Gongyi offers a broad spectrum of industrial equipment, reflecting the growing capabilities and quality standards of Chinese manufacturing.

- Cangzhou Qiulin Construction Machine Manufacturing Co., Ltd. (China): Known for their robust and reliable machinery, Cangzhou Qiulin exemplifies the strength of Chinese manufacturers in delivering practical, high-value solutions.

These companies, along with specialized grinder manufacturers such as those producing Jainnher centerless grinding machine, Lidkoping centerless grinding machine, Mikrosa centerless grinding machine, Palmary centerless grinding machine, and Paragon centerless grinding machine, collectively demonstrate the global push towards more sophisticated and efficient industrial processes.

Market Outlook & Opportunities: The Future of Flawless Surfaces

The market for polishing machines is poised for significant expansion, driven by continuous advancements in material science and an increasing demand for precision components across aerospace, automotive, medical, and general manufacturing sectors. Upcoming trends indicate a strong buyer demand for systems that offer not just speed and precision, but also adaptability and data-driven insights.

- Automation & Robotics: The integration of robotic arms for loading, unloading, and even complex polishing tasks will become standard, reducing human intervention and enhancing consistency.

- Smart Manufacturing (Industry 4.0): Polishing machines will be integral to smart factories, communicating with other equipment and central systems to optimize entire production lines. Data analytics will drive efficiency, quality control, and preventive maintenance for all types of centerless grinder applications.

- Sustainability & Energy Efficiency: Environmentally friendly designs, reduced energy consumption, and efficient waste management systems will be critical purchasing factors, reflecting global regulatory pressures and corporate responsibility goals. This applies to everything from a small bar centerless grinder to a large industrial system.

- Customization & Flexibility: The ability to quickly reconfigure machines for different product specifications or material types will be a key differentiator, appealing to manufacturers with diverse portfolios.

Opportunities abound for businesses willing to invest in these sophisticated technologies. The payoff comes in enhanced product quality, faster time-to-market, and significant long-term operational savings.

Buyer/Business Takeaways: Investing in Tomorrow’s Finishing Solutions

For B2B decision-makers, the message is clear: investing in advanced polishing machines is no longer just about improving surface finish; it's about future-proofing your operations and gaining a significant competitive edge. Here’s why and how:

- Why Invest Now? Modern industrial metal polishing machines offer unparalleled precision, reducing material waste and rework. Their automation capabilities address labor challenges and ensure consistent, high-quality output, directly impacting your bottom line and reputation. Furthermore, machines like the advanced bar centerless grinder or an internal centerless grinding machine dramatically improve throughput and product aesthetics.

-

Partnering with Chinese Manufacturers: Chinese manufacturers like Xingtai Xieli have evolved significantly, offering a compelling blend of advanced technology, robust construction, and competitive pricing. When considering a partnership, look for:

- A proven track record and specialization in your required machine type (e.g., engine centerless grinder machine for sale or industrial metal polishing machine).

- Strong R&D capabilities, indicating a commitment to innovation (e.g., integrating IoT or AI).

- Comprehensive after-sales support, spare parts availability, and technical assistance.

- Certifications and adherence to international quality standards.

- Future-Proof Strategies: To ensure your investment stands the test of time, prioritize machines with modular designs, upgradeability, and smart capabilities that can integrate into an Industry 4.0 ecosystem. Opt for manufacturers who demonstrate a clear vision for sustainability and energy efficiency in their product development. This foresight will safeguard your operations against obsolescence and new regulations.

Conclusion: Shaping the Global Polishing Machine Market

Bauma China is more than just an exhibition; it's a strategic indicator of where the global industrial machinery market is heading. For the polishing machine and centerless grinding sector, it serves as a critical platform for unveiling advanced technologies, fostering international collaboration, and setting new benchmarks for efficiency and precision. The innovations showcased by manufacturers like Xingtai Xieli, alongside other global leaders, are instrumental in shaping the future of metal finishing, making it smarter, faster, and more sustainable.

As you consider enhancing your operational capabilities with next-generation finishing solutions, exploring the offerings from these industry pioneers is essential.

Discover Xingtai Xieli's Round Bar Polishing Machines & More

Connect with us to explore how our advanced industrial metal polishing machines, including robust bar centerless grinders and specialized engine centerless grinder machine for sale options, can revolutionize your production processes.