The Rise of Polishing Machines for Stainless Steel Pipe Manufacturing

In recent years, the stainless steel industry has seen significant advancements in technology, particularly regarding the manufacturing of stainless steel pipes. Among the various innovations, polishing machines have emerged as a key player, transforming production processes and enhancing product quality. Companies specializing in stainless steel pipe manufacturing are increasingly adopting these advanced polishing systems to meet the growing demand for high-quality, aesthetically pleasing products.

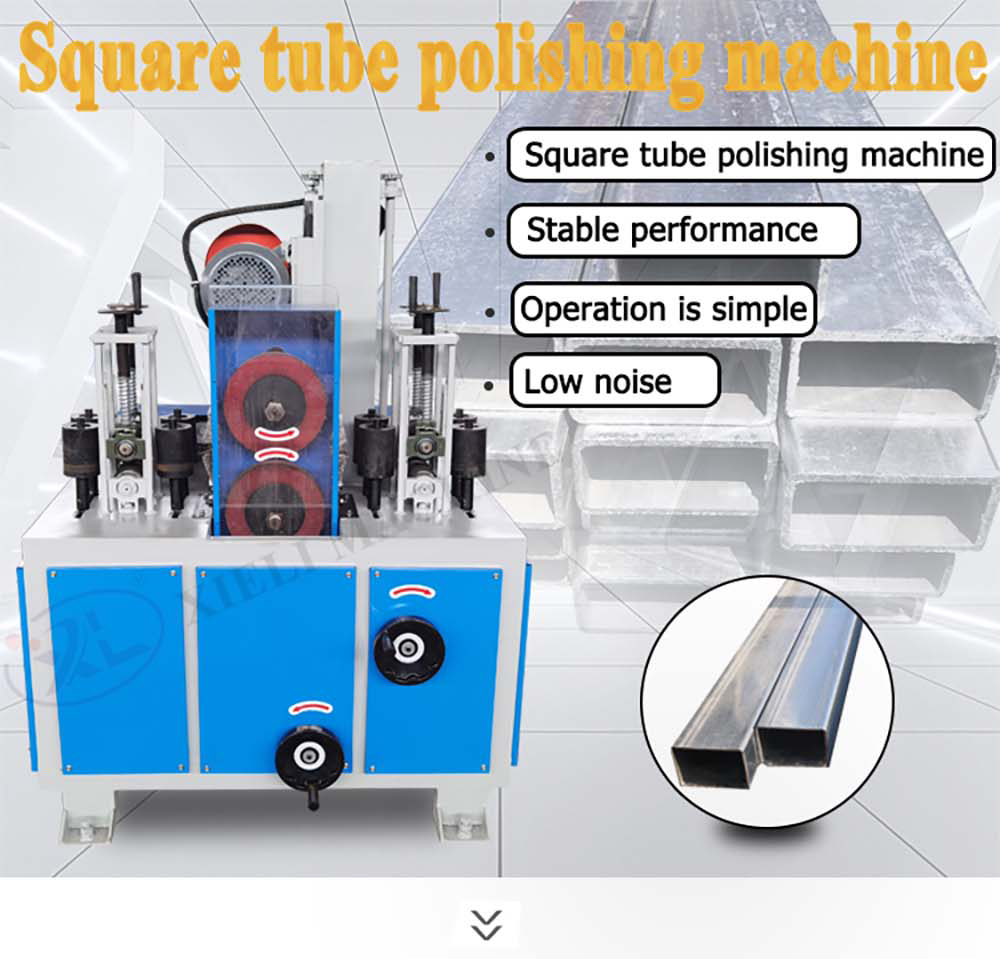

Polishing machines serve a crucial role in the finishing process of stainless steel pipes. The primary function of these machines is to remove surface imperfections, burrs, and contaminants that may occur during the manufacturing process. A well-polished stainless steel pipe not only looks more attractive but also offers improved corrosion resistance, making it ideal for various applications across different industries. From construction and architecture to food processing and pharmaceuticals, polished stainless steel pipes deliver exceptional performance and durability.

The benefits of using polishing machines are manifold. First and foremost, they ensure a consistent finish, which is essential for industries that require stringent standards and specifications. Manual polishing can result in uneven surfaces, varying degrees of luster, and the potential for human error. In contrast, modern polishing machines utilize advanced technology, such as computer numerical control (CNC), to achieve precise and uniform results. This level of accuracy not only enhances the aesthetic qualities of stainless steel pipes but also contributes to their overall functionality and lifespan.

Moreover, polishing machines significantly improve production efficiency. The automation of polishing processes reduces the time and labor required to finish pipes, allowing manufacturers to increase their output without compromising quality. In an industry where demand is continually evolving, the ability to streamline production processes is a distinct competitive advantage. Companies that invest in high-quality polishing machines often find themselves better equipped to meet client demands and adapt to market changes.

polishing machine for stainless steel pipe companies

Furthermore, with the growing emphasis on sustainability and eco-friendliness, modern polishing machines have been designed to minimize environmental impact. Many of these machines utilize advanced filtration systems to capture and recycle polishing compounds and dust, which not only reduces waste but also lowers operational costs. Companies that prioritize sustainability can not only enhance their corporate social responsibility (CSR) profile but also appeal to an increasingly environmentally conscious customer base.

Choosing the right polishing machine is crucial for companies involved in stainless steel pipe manufacturing. Factors such as machine size, polishing speed, and the types of abrasives used should be carefully considered based on the specific needs of the operation. Additionally, support and training provided by the machine manufacturers play an integral role in the successful integration of these machines into existing production lines. Companies are encouraged to conduct thorough research and even seek demonstrations before committing to a particular model.

The investment in polishing machines also opens the door to innovative possibilities regarding product development. As manufacturers become adept at achieving high-quality finishes, they may explore new designs and applications for their stainless steel pipes. For example, the energy sector is continually seeking more efficient piping solutions, while the architectural industry demands aesthetically pleasing materials for modern buildings. Successfully harnessing the capabilities of polishing machines can thus lead to new business avenues and increased profitability.

In conclusion, polishing machines for stainless steel pipe manufacturing represent a significant advancement in the industry. With their ability to deliver consistent finishes, enhance production efficiency, and support sustainability, these machines are becoming indispensable tools for manufacturers aiming to thrive in a competitive market. As technology continues to progress, it’s likely that the capabilities of polishing machines will expand, offering even greater opportunities for innovation and growth in the stainless steel sector. In a world where quality and efficiency are paramount, investing in this technology is not just a trend—it's a necessity for success.