The Pipe Polishing Machine Market Suppliers and Exporters

In recent years, the demand for pipe polishing machines has surged due to the increased need for polished pipes in various industries, including construction, automotive, and manufacturing. These machines are essential for enhancing the aesthetic and functional qualities of pipes, making them more appealing to consumers while ensuring they meet industry standards for quality and performance. This article explores the landscape of pipe polishing machine suppliers and exporters, highlighting their significance in the global market.

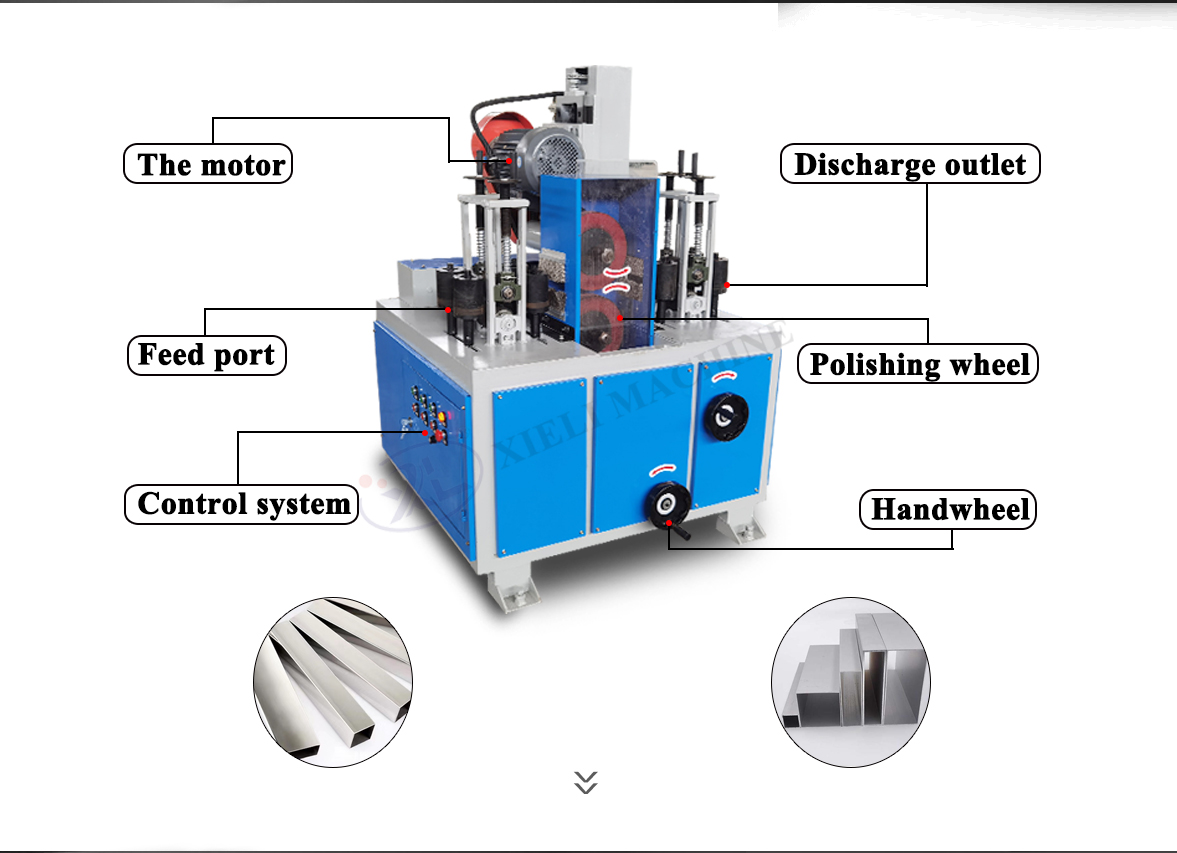

Understanding Pipe Polishing Machines

Pipe polishing machines are specialized equipment designed to polish and finish metal pipes to achieve a smooth, shiny surface. This process not only improves the appearance of the pipes but also enhances their resistance to corrosion and wear, which is critical in many applications. These machines vary in size, capacity, and technology, catering to different industries' specific requirements.

Key Players in the Market Suppliers and Exporters

The market for pipe polishing machines is characterized by a mix of local and international suppliers and exporters. These entities play a vital role in ensuring that the machines are available to manufacturers and businesses worldwide. Here are some notable characteristics and trends among these suppliers and exporters

1. Diversity of Offerings Suppliers offer a range of pipe polishing machines, including manual, semi-automatic, and fully automated systems. This diversity allows businesses to choose machines that best fit their production needs, budget, and operational capabilities.

2. Technological Advancements The industry is witnessing rapid technological advancements, with suppliers continuously improving machine efficiency and effectiveness. Features such as digital controls, automated feeding systems, and advanced polishing techniques are now commonplace, contributing to higher productivity and lower operational costs.

3. Customization Many suppliers provide customization options, allowing businesses to tailor machines to specific requirements. This adaptability is essential in industries where pipe specifications can vary greatly. Custom solutions can include alterations in size, capacity, and polishing mechanisms.

pipe polishing machine suppliers exporters

4. Export Challenges While there is a growing global demand for pipe polishing machines, exporters face challenges such as international trade regulations, tariffs, and logistical complexities. Successful exporters are those who can navigate these challenges while maintaining competitive pricing and ensuring timely delivery.

5. Market Growth Emerging markets in Asia, Africa, and South America present significant opportunities for growth. As industries in these regions expand, the demand for high-quality pipe polishing machines is likely to increase. Suppliers and exporters are actively seeking to establish partnerships and distribution networks in these markets to capitalize on this trend.

Quality Assurance and Compliance

Quality assurance is crucial in the pipe polishing machine industry. Suppliers must adhere to international standards to ensure the machines they produce meet safety and efficiency requirements. Compliance with regulations such as ISO certifications not only enhances the credibility of suppliers but also builds trust with customers.

The Future of the Pipe Polishing Machine Market

Looking ahead, the pipe polishing machine market is poised for growth. With increasing automation in manufacturing processes, there will be a rising demand for more efficient and effective polishing machines. Sustainability and energy efficiency concerns will also drive innovation, as manufacturers seek to minimize environmental impact and reduce operating costs.

Furthermore, as industries evolve and new materials are introduced, suppliers and exporters will need to adapt their offerings accordingly. Staying attuned to market trends and customer demands will be essential for suppliers and exporters seeking to maintain a competitive edge in this dynamic landscape.

Conclusion

The role of pipe polishing machine suppliers and exporters is critical in meeting the growing global demand for quality metal pipes. As industries expand and technologies evolve, these entities must adapt to remain relevant in a competitive market. By focusing on innovation, customization, and quality assurance, suppliers can continue to thrive in the ever-changing landscape of manufacturing equipment, ensuring that they meet the needs of businesses around the world.