Understanding Pipe Polishing Machine Suppliers and Their Importance in Manufacturing

In the modern landscape of manufacturing and industrial processes, the role of specialized equipment cannot be overstated. One such vital piece of machinery is the pipe polishing machine. This technology is essential for achieving a smooth, aesthetically pleasing, and corrosion-resistant finish on various types of pipes. As industries continue to evolve, the demand for high-quality pipe polishing machines has surged, leading to the emergence of numerous suppliers and companies specializing in this field.

What is a Pipe Polishing Machine?

A pipe polishing machine is designed to enhance the surface finish of metal pipes through mechanical polishing. These machines are capable of removing oxidation, discoloration, and imperfections that may have resulted from earlier manufacturing processes or handling. By utilizing abrasive materials, pipe polishing machines ensure uniformity and shine, which are critical for applications in industries such as automotive, construction, and oil and gas.

Key Features of Pipe Polishing Machines

When considering suppliers of pipe polishing machines, it is crucial to examine the features these machines offer. Advanced models often come equipped with

1. Automated Processes Automation can significantly enhance efficiency. Machines that offer programmable operations allow for consistent results and reduced labor costs. 2. Versatility Some machines can handle various pipe diameters and materials, making them suitable for diverse industrial applications.

3. Quality Assurance Renowned suppliers provide machines that incorporate technology to monitor and control polishing processes, ensuring that every piece retains the desired specifications.

4. Safety Features Given the industrial context of these machines, suppliers must prioritize safety by embedding features that protect operators from accidents.

5. Affordability vs. Quality While there are many affordable options in the market, companies must weigh cost against quality and durability to avoid future losses from unreliable equipment.

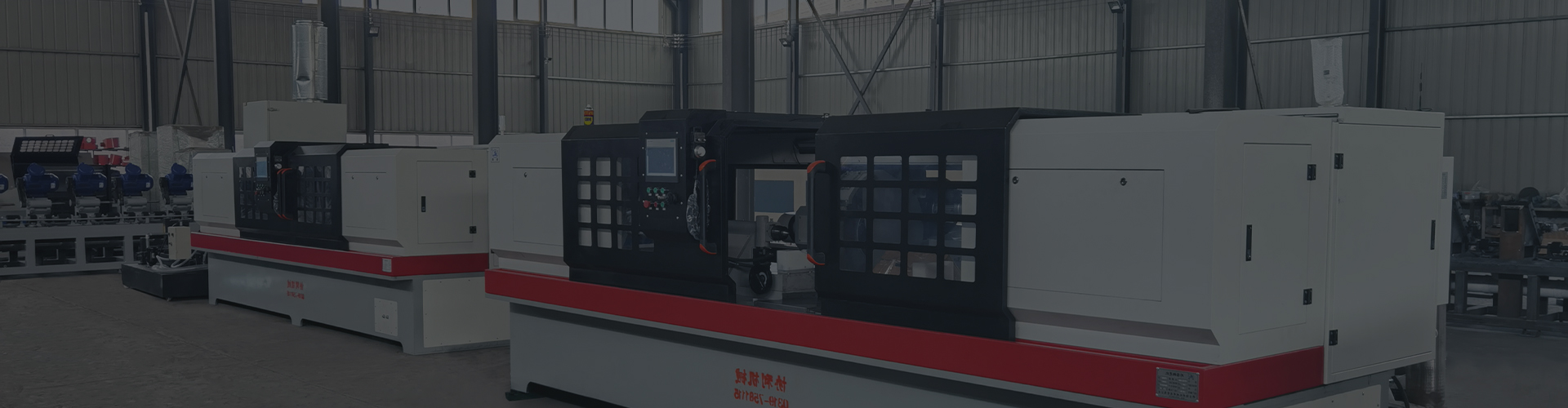

pipe polishing machine suppliers companies

Choosing the Right Supplier

The choice of supplier is vital to ensuring the successful integration of pipe polishing machines into a manufacturing operation. Here are some factors to consider

1. Reputation Start by researching potential suppliers’ reputations. Look for reviews, testimonials, and case studies that demonstrate their reliability and service quality.

2. Technical Support and Maintenance A good supplier should offer comprehensive technical support and maintenance services. This is crucial for minimizing downtime and extending the lifespan of the equipment.

3. Customization Options Many industries have specific requirements. Suppliers that offer customization can be highly beneficial, as they understand that a one-size-fits-all approach often does not cater to varying manufacturing needs.

4. Certification and Standards Compliance Ensure that the machines comply with international safety and quality standards. Certifications serve as a reassuring indicator of a supplier’s commitment to excellence.

5. Post-Sale Service Reliable suppliers will offer warranties and robust after-sale services, ensuring that any issues are dealt with promptly.

Conclusion

The market for pipe polishing machine suppliers is dynamic and continually evolving, driven by advances in technology and the increasing demand for high-quality finishes in manufacturing. By understanding the essential features of pipe polishing machines and how to choose the right supplier, businesses can optimize their production processes and maintain the highest standards of quality. Investing in a quality pipe polishing machine from a reputable supplier is a strategic move that can significantly enhance operational efficiency and output quality in any manufacturing setup. As industries grow more competitive, having the right equipment plays a crucial role in maintaining an edge.