The Importance of Pipe Polishing Machine Manufacturers in the Industry

In the modern manufacturing landscape, efficiency and precision are paramount. One of the pivotal players in achieving these goals is the pipe polishing machine. This specialized equipment plays a crucial role in the production and finishing of pipes, which are essential components across various industries, including construction, automotive, and oil and gas. As the demand for high-quality pipes increases, the role of pipe polishing machine manufacturers becomes more pronounced.

Understanding Pipe Polishing

Pipe polishing is a vital finishing process that enhances the aesthetic and functional properties of pipes. This procedure removes imperfections, burrs, and oxidation from the surface, resulting in a smoother and more appealing finish. Moreover, polished pipes exhibit better resistance to corrosion and wear, extending their lifespan and performance reliability. Pipes used in sensitive applications, such as food processing or pharmaceuticals, require rigorous polishing to meet stringent hygiene standards.

The Role of Manufacturers

Pipe polishing machine manufacturers are the backbone of this essential operation. They design and produce machinery that meets the diverse needs of various industries. A well-manufactured polishing machine can dramatically improve productivity and reduce operational costs.

1. Innovation and Technology Leading manufacturers invest heavily in research and development to innovate their polishing machines. Advanced technologies, including computer numerical control (CNC) and automated systems, have revolutionized pipe polishing processes. These machines enable precise control over polishing parameters, ensuring consistent quality and minimizing human error.

2. Customization Different industries require different specifications for their pipes. Manufacturers often provide customization options that allow clients to tailor their machines according to specific requirements. This flexibility ensures that businesses can achieve optimal results for their particular applications.

3. Quality Assurance Pipe polishing machine manufacturers adhere to stringent quality control processes. The machines are designed to meet international standards, ensuring reliable performance. Manufacturers often provide certifications and warranties, giving clients peace of mind regarding their investments.

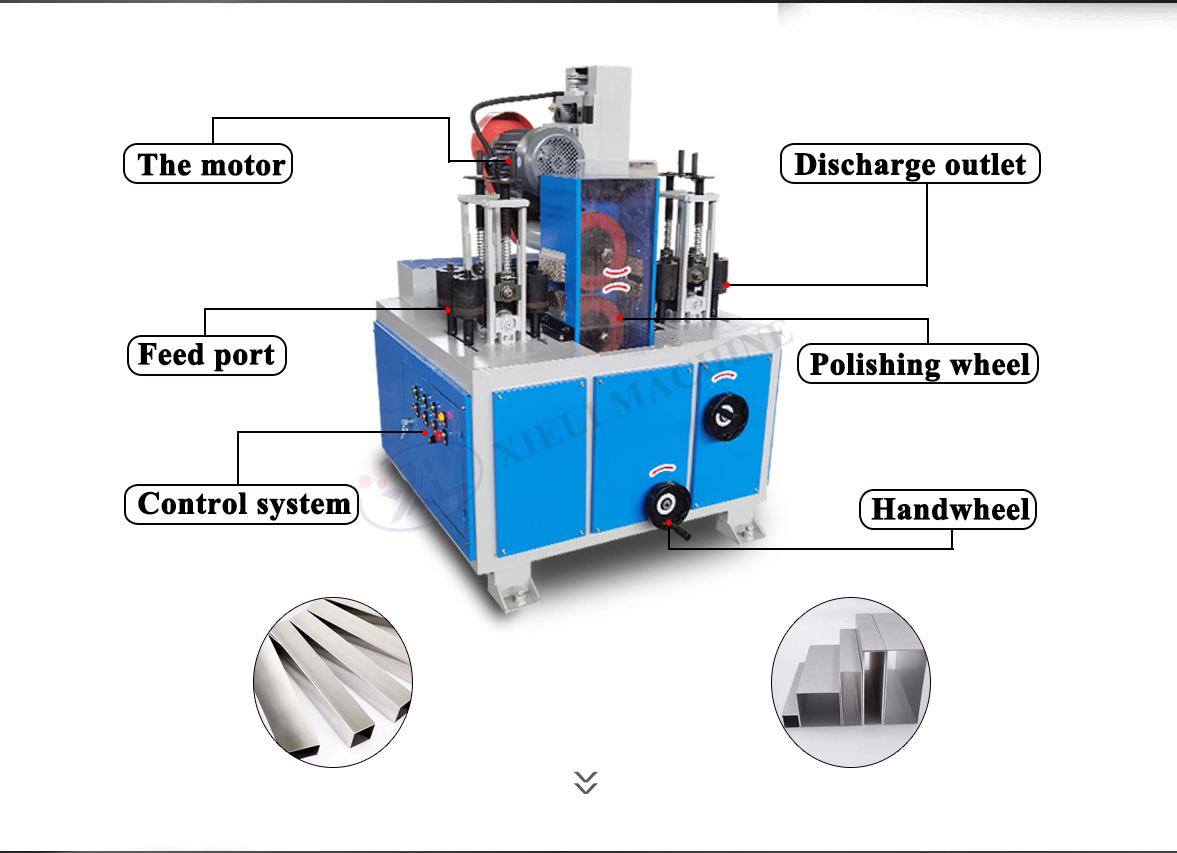

pipe polishing machine manufacturers product

4. Training and Support Beyond supplying the machinery, reputable manufacturers offer comprehensive training and support to their clients. This service ensures that operators can use the equipment effectively, maximizing its potential and minimizing downtime due to user errors.

Market Trends

The pipe polishing machine market is witnessing significant growth, driven by several factors

- Increasing Demand in End-User Industries As industries such as automotive, construction, and energy expand, the demand for high-quality pipes is on the rise. This increase directly correlates with the growing need for efficient polishing solutions.

- Sustainability Focus Manufacturers are increasingly prioritizing sustainable practices. Advanced polishing machines often use less energy and generate less waste than older models, helping businesses reduce their environmental footprint.

- Globalization With the global trade of goods, manufacturers are finding new markets for their pipe polishing machines. Emerging economies are investing in infrastructure, leading to increased demand for quality manufacturing equipment.

Conclusion

The role of pipe polishing machine manufacturers is critical in today's manufacturing ecosystem. They not only provide the machinery necessary for achieving high-quality pipes but also drive innovation and sustainability within the industry. As demand for precision-engineered products continues to rise, so too will the importance of these manufacturers. Companies looking to enhance their production capabilities should carefully evaluate potential manufacturers, considering factors such as technology, customization options, and support services. By choosing the right partner, businesses can ensure they remain competitive in the ever-evolving marketplace.

In conclusion, the significance of pipe polishing machine manufacturers cannot be overstated. They are essential to enhancing the quality, efficiency, and sustainability of pipe production, ultimately contributing to the success of various industries. As technology advances and customer expectations rise, these manufacturers will continue to evolve, shaping the future of piping solutions.