The Role of Pipe Grinding Machine Companies in Modern Manufacturing

In the world of manufacturing, precision, efficiency, and quality are paramount. Among the myriad of tools and machines that facilitate these standards, pipe grinding machines play a vital role. These machines are essential for processing metal pipes, ensuring they meet the stringent quality demands of various industries, including construction, automotive, aerospace, and more. Pipe grinding machine companies are at the forefront of this technological advancement, continually developing innovative solutions to meet the evolving needs of their clients.

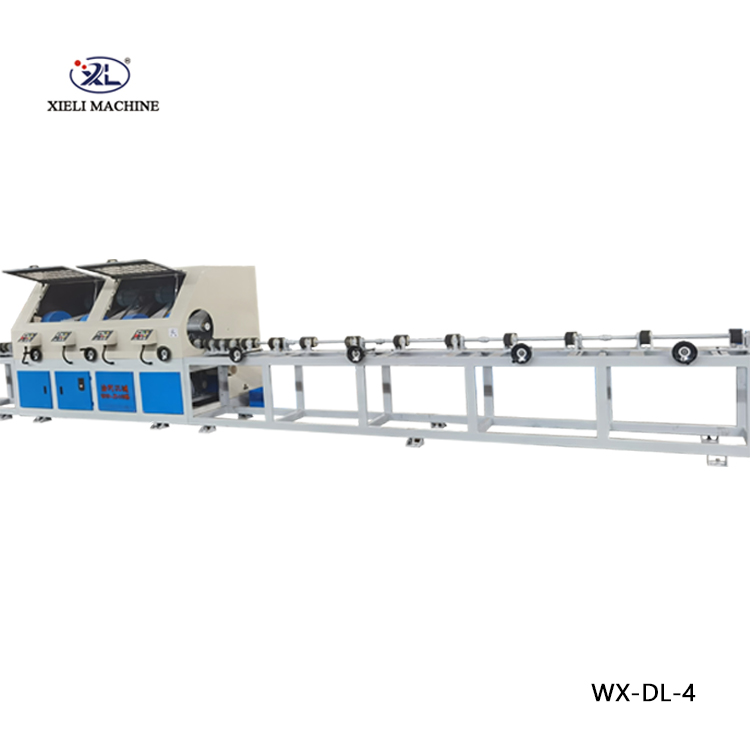

Pipe grinding machines are designed to accomplish a variety of tasks, including removing surface imperfections, preparing pipes for coating or welding, and achieving specific dimensional tolerances. The grinding process enhances not only the aesthetic quality of the pipes but also their mechanical properties, making them safer and more reliable for end-users. Companies that specialize in manufacturing these machines often invest heavily in research and development, resulting in advanced models that incorporate new technologies such as automation and real-time monitoring.

One key driver for the growth of pipe grinding machine companies is the increasing demand for high-quality, durable pipes in the construction and manufacturing sectors. With the continuous expansion of infrastructure required to support urban growth, the need for reliable piping solutions has surged. As a response, companies are producing machines capable of handling a wide range of materials, including stainless steel, carbon steel, and aluminum, which are commonly used in various piping applications.

pipe grinding machine companies

In addition to their focus on quality, many pipe grinding machine companies are prioritizing sustainability. As industries become more aware of their environmental impact, manufacturers are challenged to produce more energy-efficient and eco-friendly machinery. Modern pipe grinding machines are now designed to minimize waste and reduce energy consumption, aligning with global sustainability goals. This not only benefits the planet but also helps companies reduce operational costs, making them more competitive in the market.

Furthermore, the rise of customization in manufacturing has prompted pipe grinding machine companies to offer tailored solutions for their clients. Every project has unique requirements, and companies that can provide personalized machinery will have a distinct advantage. By collaborating closely with clients to understand their specific needs, these manufacturers can develop machines that enhance productivity, increase throughput, and ensure that pipes are prepared to exact specifications.

The global market for pipe grinding machines is also becoming increasingly competitive, with numerous players emerging internationally. Companies that embrace the latest technological advancements, such as digitalization and artificial intelligence, will be pivotal in driving the industry forward. These innovations enable better performance tracking, predictive maintenance, and overall improved operational efficiency.

In conclusion, pipe grinding machine companies are an integral part of the modern manufacturing landscape. By delivering high-quality machinery that meets the demands of diverse industries, they play a significant role in ensuring quality and efficiency in pipe production. As technology continues to evolve, these companies must stay ahead of industry trends to remain competitive, focusing on sustainability, customization, and innovation. The future of pipe grinding machines looks promising, with endless possibilities for growth and advancement in manufacturing.