The Evolution and Impact of Pipe Belt Polishing Machine Companies in the Manufacturing Sector

In the manufacturing industry, the emphasis on product quality and surface finish has driven significant advancements in technology and machinery. Among these developments, pipe belt polishing machines have emerged as a critical tool for achieving high standards of surface finish on metal pipes. As companies specialize in this technology, they play an essential role in enhancing efficiency, sustainability, and quality across various sectors.

Pipe belt polishing machines are designed to polish and finish the surface of pipes and tubes, achieving a mirror-like quality that not only enhances aesthetic appeal but also improves corrosion resistance. This is particularly vital in industries such as automotive, aerospace, and food processing, where surface quality can directly impact product performance and longevity.

The rise of companies specializing in pipe belt polishing machines has been driven by a growing demand for high-quality metal products. These companies have evolved to integrate advanced technology into their machinery, automating the polishing process to enhance precision and reduce production times. Features such as programmable logic controllers (PLCs) and adjustable speed settings allow operators to customize the polishing process based on the specific requirements of the material and desired finish.

Moreover, advancements in abrasive materials have significantly improved the performance of pipe belt polishing machines. Modern machines utilize a variety of belts, each designed for specific polishing tasks. For instance, ceramic belts are known for their durability and consistency, while non-woven belts provide a superior finish without sacrificing speed. Such innovations have enabled manufacturers to meet increasingly stringent industry standards while maintaining competitiveness in the global market.

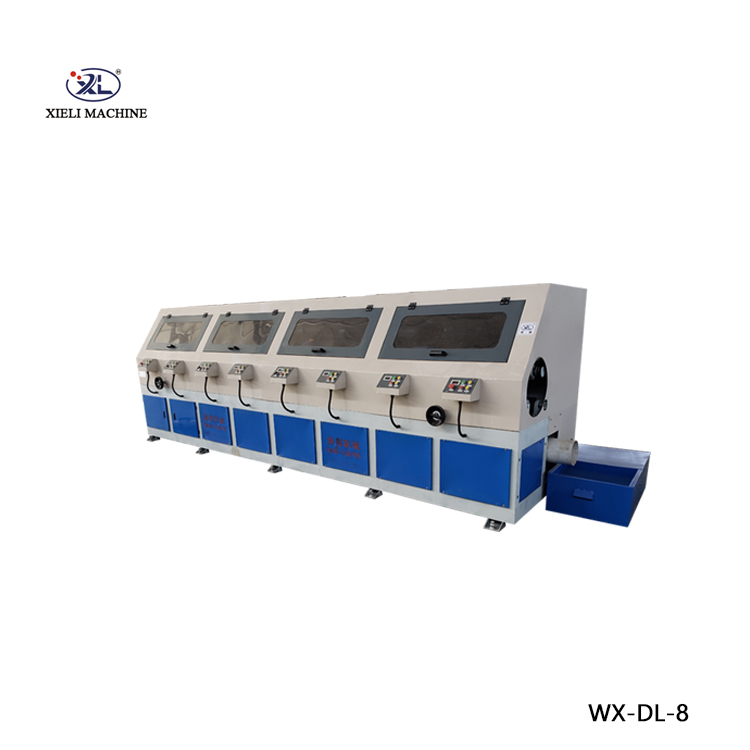

pipe belt polishing machine companies

The emphasis on sustainability has also influenced the operations of pipe belt polishing machine companies. With greater awareness of environmental impacts, many manufacturers are now focused on creating energy-efficient machines that reduce waste and consume less power. Some companies have implemented closed-loop systems that recycle polishing materials, thereby minimizing environmental footprints. This shift not only supports corporate social responsibility goals but also appeals to clients who prioritize sustainable practices in their supply chains.

The role of pipe belt polishing machine companies extends beyond manufacturing equipment. Many of these companies offer comprehensive solutions that include training, maintenance services, and support for integrating their machines into existing production lines. This holistic approach ensures that clients maximize the return on their investment, leading to improved productivity and quality outcomes. Technicians are trained to operate the equipment effectively, ensuring they can troubleshoot issues and maintain optimal performance levels.

Globalization has further fueled the growth of pipe belt polishing machine companies. As trade barriers diminish, manufacturers are finding new markets for their products. Companies that once operated regionally have expanded their reach internationally, capitalizing on emerging markets and the demand for high-quality finished metal products worldwide. However, this expansion presents challenges as well, necessitating that companies remain agile and adapt their technologies and services to meet diverse cultural and regulatory standards across different regions.

As we look to the future, the innovation landscape for pipe belt polishing machine companies appears vibrant. The integration of artificial intelligence (AI) and machine learning into overseeing polishing processes promises to revolutionize the industry. AI can analyze data in real-time, enhancing the precision of polishing by learning optimal settings based on various factors such as material type and desired finish. This would not only streamline production but also further elevate the quality of finished products.

In conclusion, pipe belt polishing machine companies are vital players in the manufacturing sector, contributing to the enhancement of product quality and operational efficiency. Their commitment to innovation, sustainability, and customer support has positioned them as essential partners for industries relying on high-quality metal products. As technology continues to evolve, these companies will undoubtedly remain at the forefront of manufacturing advancements, driving improvements that benefit both businesses and consumers alike. The future looks promising, with the potential for revolutionary changes that could redefine manufacturing standards and practices in the years to come.