Exploring the Paragon RC-12 Centerless Grinder Quotes and Insights

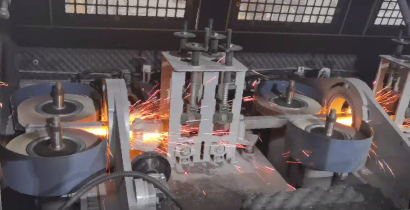

In the realm of precision machining, centerless grinders play a pivotal role in enhancing productivity and efficiency. Among the established names in this space, the Paragon RC-12 Centerless Grinder stands out due to its robust design, advanced features, and remarkable performance. This article dives into the significance of the RC-12, including quotes from industry experts and end-users who highlight its value in manufacturing.

The Paragon RC-12 is equipped with a unique design that allows for maximum stability and rigidity, ensuring high accuracy in grinding operations. A representative from a leading manufacturing firm remarked, The Paragon RC-12 has revolutionized our approach to centerless grinding. Its precision and reliability have enabled us to maintain high standards while increasing our output. This quote encapsulates the essence of the RC-12's capabilities, emphasizing how it can directly impact productivity levels in a manufacturing environment.

Exploring the Paragon RC-12 Centerless Grinder Quotes and Insights

Moreover, the RC-12's versatility is another aspect that has garnered praise from users. It is capable of grinding a wide range of materials, from hardened steels to softer metals. An engineer at a fabrication shop mentioned, We were amazed at how the RC-12 handled different materials. Its adaptability is a game-changer for our operations, allowing us to take on diverse projects without worrying about machine limitations. This capability opens up new avenues for manufacturers, enabling them to diversify their offerings and meet various customer demands.

paragon rc-12 centerless grinder quotes

In terms of precision, the Paragon RC-12 boasts high-level accuracy that can be attributed to its engineering excellence. A manufacturing consultant emphasized, The tolerances we achieve with the RC-12 are second to none. It has set a new benchmark for quality in our grinding processes. Such insights reveal how the RC-12 is not just a machine but an essential tool for businesses aiming to achieve high standards in quality control and precision engineering.

Another notable feature is the RC-12’s customizable options, which allow users to tailor the grinder to specific project requirements. An operations manager explained, We were able to customize our RC-12 to fit our specific needs, which has significantly improved our workflow and efficiency. The flexibility is invaluable for our competitive edge. The adaptability of the RC-12 to different manufacturing scenarios is a significant consideration for companies looking to optimize their processes.

Maintenance is also a topic of importance when discussing machining equipment, and the Paragon RC-12 does not disappoint. A maintenance supervisor commented, The design of the RC-12 makes maintenance straightforward. Regular upkeep is minimal, which means less downtime for repairs and more time producing parts. This aspect further solidifies the RC-12’s position as a reliable investment for factories, translating to cost savings over time.

In conclusion, the Paragon RC-12 Centerless Grinder is commendable for its advanced features, user-friendly operation, and adaptability to various materials and projects. From enhancing productivity and precision to simplifying maintenance, the RC-12 addresses many challenges faced by modern manufacturers. As industry quotes indicate, it not only meets the expectations of users but often exceeds them, making it a preferred choice among professionals in the field. For manufacturers seeking to boost efficiency and maintain high-quality standards, investing in a Paragon RC-12 is indeed a strategic decision that promises significant returns. Ultimately, the right tools can transform production capabilities, and the RC-12 exemplifies this potential in the world of centerless grinding.