The Paragon RC-12 Centerless Grinder A Comprehensive Overview

In the world of precision machining, centerless grinding machines play a crucial role due to their ability to produce high-quality, cylindrical components efficiently. Among the many options available, the Paragon RC-12 Centerless Grinder stands out as a reliable and versatile solution for various grinding applications. This article will delve into the features, benefits, and applications of the Paragon RC-12, illustrating why it has become a favored choice among manufacturers.

Key Features of the Paragon RC-12

The Paragon RC-12 Centerless Grinder is designed to handle a variety of workpiece sizes and materials while delivering exceptional precision. One of the standout features of this machine is its robust construction, which minimizes vibrations and enhances stability during operation. The machine is built with high-quality components that ensure durability and long-term performance.

The RC-12 is equipped with an easy-to-use electronic control panel that allows operators to adjust grinding parameters seamlessly. This flexibility makes it suitable for both small and large production runs. Additionally, the grinder features adjustable regulating and grinding wheel speeds, enabling users to optimize the grinding process according to the specific requirements of the material and the desired finish.

Another impressive aspect of the RC-12 is its ability to grind multiple types of materials, including metals such as steel, aluminum, and brass, as well as non-metallic materials like plastics and ceramics. This versatility broadens the machine’s applicability across various industries, including automotive, aerospace, medical, and general manufacturing.

Benefits of Using the Paragon RC-12

Investing in a Paragon RC-12 Centerless Grinder offers several advantages to manufacturers. Firstly, the machine significantly enhances productivity. Its automated features minimize downtime and allow for continuous operation, which is crucial for meeting high-volume production demands.

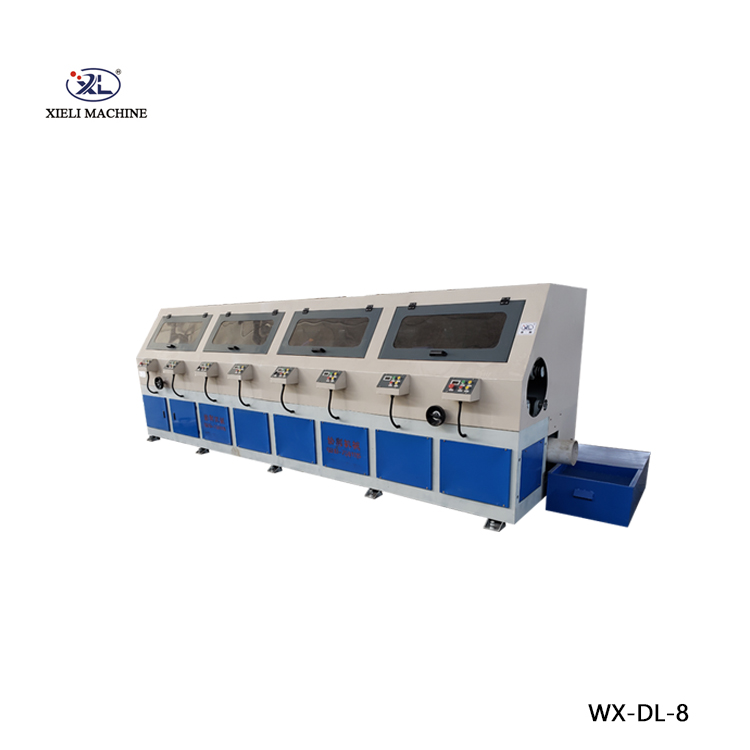

paragon rc-12 centerless grinder product

Moreover, the precision grinding capabilities of the RC-12 contribute to reduced material wastage and improved dimensional accuracy. The machine's advanced grinding technology ensures that tolerances are consistently met, leading to higher quality end products. This reliability can boost customer satisfaction and strengthen a company's reputation in the marketplace.

Training and maintenance are also simplified with the RC-12. The intuitive design of the control system allows for quick operator training, reducing the learning curve associated with complex machinery. Furthermore, the durability and reliability of the components lower maintenance costs, making it a cost-effective investment over its operational lifespan.

Applications of the Paragon RC-12 Centerless Grinder

The applications for the Paragon RC-12 are vast, making it a valuable addition to any production floor. It is commonly used for processing precision components such as shafts, rods, pins, and tubing. Industries that benefit from the RC-12 include automotive, where it is used for grinding axle components and gears, and the medical field, where it helps in producing intricate surgical instruments and devices.

In addition, the RC-12 can support the manufacturing of various consumer products, enhancing the capacity of companies in sectors such as electronics, furniture, and appliances to produce parts with high accuracy and excellent surface finish.

Conclusion

The Paragon RC-12 Centerless Grinder represents a significant advancement in the field of precision grinding. With its combination of durability, versatility, and precision, it meets the diverse needs of modern manufacturing. By integrating the RC-12 into their production processes, companies can improve workflow efficiency, reduce costs, and enhance product quality. As industries continue to demand greater precision and efficiency, machines like the Paragon RC-12 will remain at the forefront of machining technology, enabling manufacturers to thrive in a competitive market.