The Importance of OEM Metal Polishing Machines and Their Pricing

In today’s competitive manufacturing landscape, the quest for quality and efficiency reigns supreme. Among the key processes that contribute to the production of high-quality metal products is metal polishing. As industries increasingly strive for perfection in their output, the demand for OEM (Original Equipment Manufacturer) metal polishing machines is on the rise. This article explores the significance of these machines, factors influencing their price, and considerations for potential buyers.

Understanding OEM Metal Polishing Machines

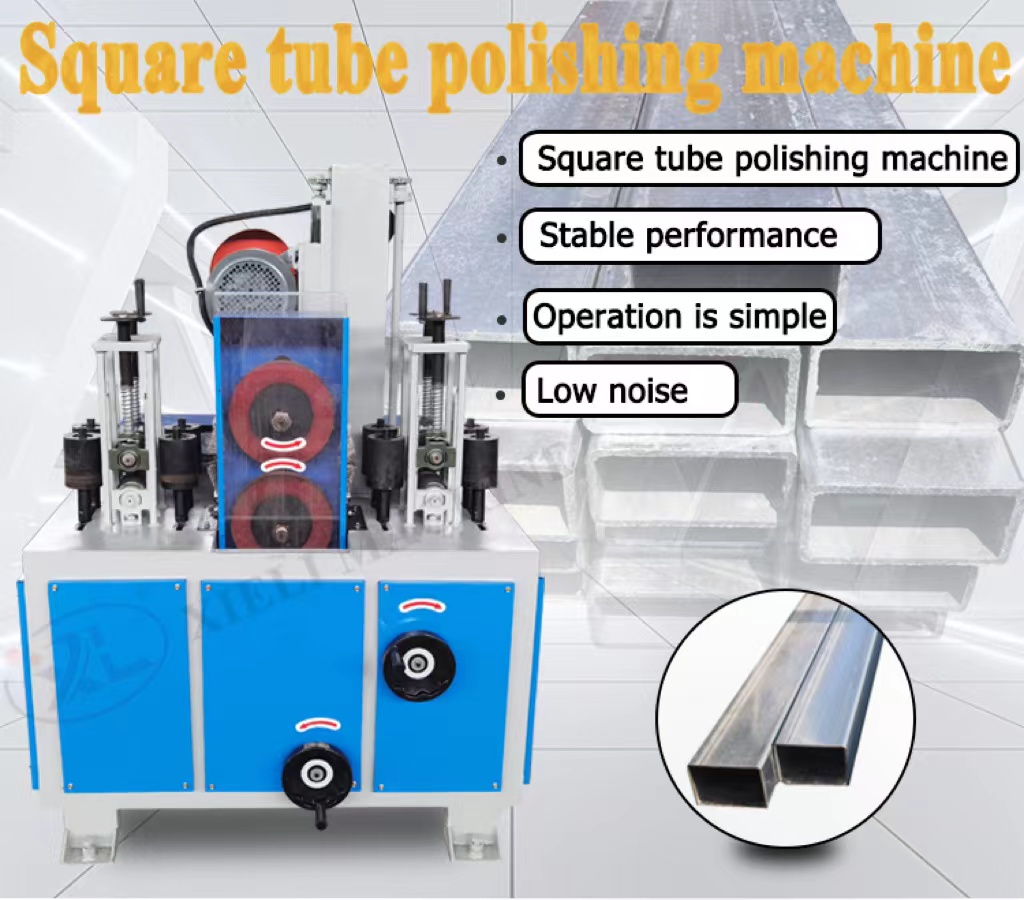

OEM metal polishing machines are specialized equipment designed for polishing metal surfaces to achieve a high gloss finish. These machines cater to various industries, including automotive, aerospace, jewelry, and electronics, where precise finishing is essential. The term 'OEM' indicates that these machines are manufactured by a company that sells them under another company’s brand name. This arrangement often allows for customization, enabling manufacturers to obtain equipment tailored to their specific needs.

The Role of Metal Polishing in Manufacturing

The process of metal polishing involves removing imperfections and enhancing the aesthetic appeal of metal surfaces. High-quality polishing not only improves the appearance but also increases corrosion resistance and durability. For manufacturers, investing in an efficient OEM metal polishing machine can lead to higher product quality, reduced labor costs, and improved production rates.

Factors Influencing the Price of OEM Metal Polishing Machines

1. Machine Specifications The complexity and capabilities of the polishing machine significantly affect its price. Basic models designed for simple tasks may be more affordable, while advanced machines with automated features, multiple polishing heads, and programmable settings will generally command higher prices.

2. Material and Build Quality The materials used in constructing the machine also play a pivotal role in pricing. Machines made from high-grade steels and advanced composites may cost more upfront but often provide increased durability and lifespan, leading to long-term savings for manufacturers.

oem metal polishing machine price

3. Brand Reputation Established brands with a good reputation for reliability and performance may charge a premium for their products. However, their machines often come with better customer support and warranties, justifying the higher investment for many customers.

4. Customization Custom-built machines tailored to specific requirements typically come at a higher cost than off-the-shelf solutions. If a manufacturer requires unique specifications, the additional investment might be worth the benefits of improved efficiency and effectiveness in their operations.

5. Technological Features The inclusion of advanced technology such as automation, smart controls, and integration with other manufacturing operations may raise the price of polishing machines. However, these features can enhance productivity and reduce labor costs, improving overall return on investment.

Budgeting for an OEM Metal Polishing Machine

When considering the purchase of an OEM metal polishing machine, companies should conduct a thorough cost-benefit analysis. While high-quality machines may come with a higher initial price tag, the long-term advantages associated with durability, efficiency, and precision can lead to significant savings and revenue growth.

It is also advisable for manufacturers to engage with multiple suppliers to compare prices and features. Additionally, seeking out customer reviews and testimonials can provide valuable insights into the performance and reliability of the machines.

Conclusion

In summary, OEM metal polishing machines play a crucial role in enhancing the quality of metal products across various industries. While the price of these machines can vary significantly due to multiple factors, understanding these variables will help manufacturers make informed decisions. By investing in the right machine, businesses can not only boost their production efficiency but also ensure they meet the high standards of quality demanded by today’s consumers. In a world where every detail counts, the importance of a polished finish should never be underestimated.