OEM Homemade Centerless Grinder Crafting Precision and Efficiency

In the world of precision machining, centerless grinding stands out as an essential process for shaping and finishing cylindrical parts. While the commercial market for centerless grinders is dominated by large manufacturers offering robust machinery, the concept of a homemade, OEM (Original Equipment Manufacturer) centerless grinder has gained traction among hobbyists and small-scale operations. This article explores the benefits, considerations, and steps involved in creating an OEM homemade centerless grinder.

Understanding Centerless Grinding

Centerless grinding is a method where the workpiece is held between two grinding wheels, one of which is stationary while the other is rotating. This design allows for efficient grinding of cylindrical parts without the need for precise centering work, making it an ideal choice for high-volume production and intricate shapes. The process produces a high degree of accuracy and surface finish, making it integral in industries like automotive, aerospace, and medical devices.

Advantages of a Homemade Centerless Grinder

1. Cost-Effectiveness One of the most significant advantages of crafting a homemade centerless grinder is the cost savings. Industrial machines can be expensive, often ranging from tens of thousands to hundreds of thousands of dollars. By building your own, you can utilize available materials and components, reducing overall costs significantly.

2. Customization An OEM homemade machine allows you to tailor the grinder according to your specific needs. You can adjust the dimensions, motor power, and grinding wheel specifications to suit particular applications, making your grinder unique and highly efficient for your specific tasks.

3. Skill Development Building a centerless grinder from scratch can be a rewarding project that enhances your engineering and machining skills. It provides insights into mechanical design, electronics, and the principles of grinding, thereby enriching your practical knowledge.

4. Flexibility A homemade grinder can be more adaptable to changes in production processes. You can modify the design or upgrade components as technology and demands evolve, ensuring longevity and relevance in your manufacturing capabilities.

Key Considerations When Building a Homemade Centerless Grinder

- Material Selection Choose durable materials that can withstand wear and tear. Steel is often preferred for critical components due to its strength, while other materials may be suitable for less stressed parts.

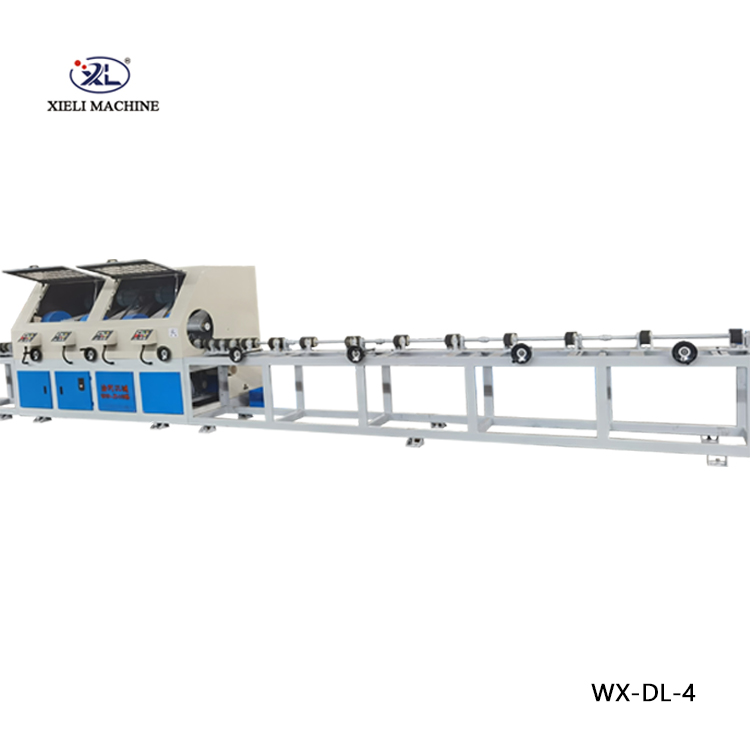

oem homemade centerless grinder

- Precision and Tolerance Ensure that the machine is built within tight tolerances. Precision is crucial in centerless grinding, as any misalignment can lead to poor machining quality.

- Motor Power Select a motor with adequate power to drive the grinding wheels effectively

. You may need to calculate the required RPM based on the grinding wheels’ specifications and the material being machined.- Safety Mechanisms Implement safety features to protect against accidents. This includes emergency shut-off switches, guards around moving parts, and dust extraction systems to maintain a clean working environment.

Steps to Build Your OEM Homemade Centerless Grinder

1. Design and Blueprint Begin with a detailed design. Sketch out the machine, identifying each component, including the grinding wheels, workpiece support, motor, and frame.

2. Gather Materials Collect all required materials and components based on your design. This may include metal sheets, shafts, bearings, and grinding wheels.

3. Fabricate Components Cut, weld, and assemble the various parts of the grinder. Ensuring precise dimensions during this phase is critical for performance.

4. Assemble the Grinder Combine all the fabricated components carefully. Make sure that the grinding wheels are aligned correctly to avoid accidents and ensure smooth operation.

5. Test and Optimize Once assembled, conduct tests to evaluate the machine's performance. Make necessary adjustments to improve efficiency and precision.

Conclusion

Creating an OEM homemade centerless grinder can be a fulfilling project that combines engineering creativity with practical application. By understanding the nuances of centerless grinding and carefully considering the construction process, you can develop a highly efficient machine tailored to your needs. Whether for personal use or small-scale production, a homemade centerless grinder represents not just a piece of equipment, but a testament to innovation and craftsmanship.