The Rise of OEM Centerless Valve Grinders A Comprehensive Overview

In the realm of precision engineering, the demand for high-quality machining tools continues to escalate. Among these tools, centerless valve grinders stand out due to their efficiency and effectiveness in processing a variety of valve types. Today, the spotlight is on OEM (Original Equipment Manufacturer) centerless valve grinders, particularly those available for sale, to explore their significance in modern manufacturing.

The Basics of Centerless Grinding

Centerless grinding is a manufacturing process that involves the grinding of surfaces with the workpiece held in place between two grinding wheels. Unlike conventional grinding, where the workpiece is held in a fixture or chuck, centerless grinding allows for greater throughput and consistency. This technique is particularly advantageous for grinding cylindrical parts, including valves used in a myriad of applications such as automotive, aerospace, and industrial machinery.

Benefits of OEM Centerless Valve Grinders

1. Precision and Accuracy OEM centerless valve grinders are designed to provide a high level of precision and repeatability. This is critical in industries where the tolerance levels are exceptionally tight, ensuring that each valve component meets specific performance standards.

2. Robust Engineering Typically, OEM grinders are constructed from high-quality materials, ensuring durability and longevity. The superior engineering facilitates better stability and reduces vibrations during the grinding process, which can otherwise lead to inaccuracies.

3. Cost-Effectiveness By investing in high-quality OEM machinery, businesses can achieve significant cost savings in the long term. Efficient grinding processes result in less material waste and reduced rework, thereby optimizing production time and costs.

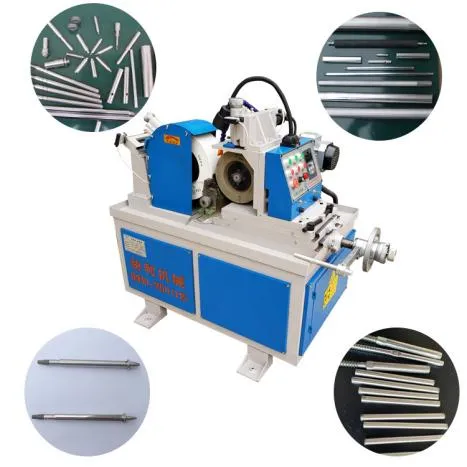

oem centerless valve grinder for sale

4. Versatility OEM centerless valve grinders can accommodate a variety of valve sizes and types, making them suitable for diverse applications across different industries. This versatility allows manufacturers to streamline their operations and reduce the number of machines needed on the shop floor.

5. Ease of Use Modern OEM centerless grinders come equipped with user-friendly interfaces and automated controls, making them accessible even for operators with limited experience. This enhances productivity by reducing training time and enables manufacturers to quickly adapt to changing production demands.

The Market for OEM Centerless Valve Grinders

With the growth of various industries, the market for OEM centerless valve grinders has evolved significantly. Many manufacturers are now offering these specialized machines for sale, catering to a global audience. Interested buyers can find a range of options, from entry-level models suitable for small businesses to advanced machines designed for high-volume production environments.

When considering the purchase of an OEM centerless valve grinder, it is essential for businesses to evaluate key factors such as the machine's specifications, the reputation of the manufacturer, and after-sales service support. Many manufacturers provide comprehensive warranties and maintenance services, further solidifying their commitment to quality and customer satisfaction.

Market Trends and Future Outlook

The increasing demand for automation and advanced manufacturing techniques is transforming the landscape of centerless grinding. Innovations such as digital monitoring systems, adaptive controls, and improved grinding wheel technologies are shaping the future of OEM centerless valve grinders. As industries continue to evolve, the need for efficient, reliable, and precise grinding solutions will remain paramount.

In conclusion, OEM centerless valve grinders represent a crucial advancement in manufacturing technology. Their precision, durability, and versatility make them indispensable for producing high-quality valve components across various sectors. As the market continues to grow, manufacturers who invest in these advanced systems will undoubtedly position themselves for success in an increasingly competitive environment. Whether a small business or a large manufacturer, considering the acquisition of an OEM centerless valve grinder could yield substantial benefits in productivity and quality.