Exploring OEM Centerless Grinder Suppliers A Comprehensive Overview

In the realm of precision manufacturing, centerless grinding stands out as a critical process for creating high-precision components. OEM (Original Equipment Manufacturer) centerless grinder suppliers play a pivotal role in this industry by providing high-quality machinery tailored to meet specific production needs. This article delves into the benefits of sourcing equipment from OEM suppliers and highlights key considerations for manufacturers.

Exploring OEM Centerless Grinder Suppliers A Comprehensive Overview

When selecting an OEM supplier for centerless grinders, one of the foremost considerations is the quality of the machinery. Reputable suppliers invest in cutting-edge technology and adhere to stringent quality control measures. These practices ensure that the grinders not only meet but exceed industry standards. High-quality OEM centerless grinders are built to last, providing durability and reliability that can significantly enhance production efficiencies.

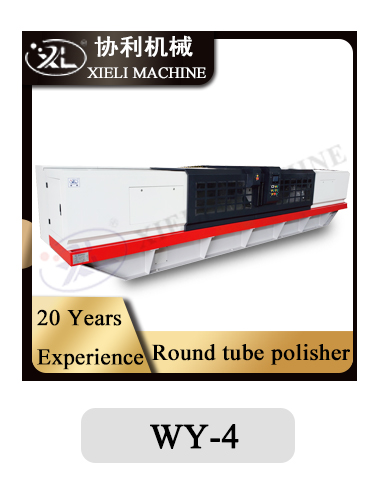

oem centerless grinder suppliers

Another important factor to consider is customization. Many OEM suppliers offer tailored solutions to meet the unique requirements of various industries. Whether the application involves creating small, intricate parts or larger components, suppliers can modify the machinery's specifications to suit specific needs. This level of customization can be a game-changer for manufacturers looking to optimize their production processes.

Furthermore, the after-sales support provided by OEM suppliers is a crucial aspect of the purchasing decision. A strong support system ensures that manufacturers can quickly resolve any issues that may arise, minimizing downtime and maintaining productivity. Supplier partnerships often extend beyond the initial sale, as many OEMs offer maintenance services, training, and spare parts availability, which can further enhance operational efficiency.

Cost-effectiveness cannot be ignored when evaluating OEM centerless grinder suppliers. While it may be tempting to choose the least expensive option, investing in quality machinery often pays off in the long run. The total cost of ownership, which includes maintenance, repairs, and efficiency, is a better indicator of a supplier's value. OEM grinders may come with a higher upfront cost but can lead to lower operational costs due to their reliability and reduced downtime.

In conclusion, OEM centerless grinder suppliers are vital partners for manufacturers aiming for precision and efficiency in their production processes. By prioritizing quality, customization, after-sales support, and overall cost-effectiveness, manufacturers can select the right OEM supplier that aligns with their specific needs. As industries continue to evolve, the role of these suppliers will remain critical in supporting innovation and enhancing productivity in manufacturing environments worldwide. Investing time in choosing the right partner will ultimately ensure sustained success and growth in an increasingly competitive market.