The Importance of OEM Centerless Grinder Rebuilders in Modern Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. When it comes to grinding operations, centerless grinders play a crucial role in achieving these objectives. However, like any complex machinery, these grinders require maintenance and occasional rebuilding to ensure optimal performance. This is where OEM centerless grinder rebuilders come into play, providing essential services that can significantly enhance the longevity and reliability of grinding equipment.

The Importance of OEM Centerless Grinder Rebuilders in Modern Manufacturing

An OEM (Original Equipment Manufacturer) centerless grinder rebuilder understands the intricacies of specific grinder models. They possess the expertise and resources to restore machines to their original specifications or even enhance them with modern technology. This involves a comprehensive assessment of the grinder, followed by the replacement of worn-out components, recalibration of the system, and testing to ensure it meets the necessary performance standards. By utilizing OEM parts, these rebuilders can guarantee the quality and compatibility of the replacements, thus mitigating the risk of future issues.

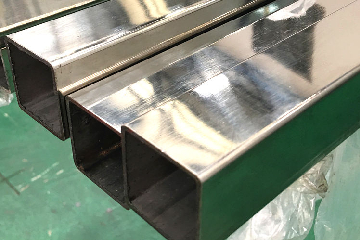

oem centerless grinder rebuilders

One of the primary benefits of utilizing OEM centerless grinder rebuilders is cost efficiency. Investing in a rebuild rather than purchasing a new machine can save manufacturers a substantial amount of money. Rebuilding also extends the machine's lifespan and helps maintain production quality, ensuring that businesses can continue to meet customer demands without the unexpected pitfalls of equipment failure.

Additionally, OEM rebuilders can introduce enhanced features during the rebuilding process. Many companies take this opportunity to integrate advanced technologies such as automation and improved control systems, which can lead to greater efficiency, reduced waste, and consistent product quality. This not only helps businesses stay competitive in a challenging market but also aligns with the growing emphasis on sustainable manufacturing practices.

Choosing the right OEM centerless grinder rebuilder is crucial. Manufacturers should look for companies with a proven track record, strong customer testimonials, and comprehensive warranty options. It's also beneficial to select a rebuilder that can provide ongoing support and maintenance services, ensuring that the machines continue to operate at peak performance long after the rebuild is completed.

In conclusion, OEM centerless grinder rebuilders are invaluable partners in the world of manufacturing. They not only facilitate the rejuvenation of aging machinery but also play a pivotal role in enhancing operational efficiency and product quality. As the manufacturing landscape continues to evolve, the expertise offered by these rebuilders will remain essential for companies aiming to thrive in an increasingly competitive environment. Investing in rebuilding services is not just about restoring equipment—it's about securing a company’s future in manufacturing excellence.