Understanding OEM Centerless Grinders A Key Component in Precision Manufacturing

Centerless grinding is a well-established manufacturing process that is essential for producing high precision components in various industries, including automotive, aerospace, and medical manufacturing. At the heart of this process is the centerless grinder, and when we talk about OEM (Original Equipment Manufacturer) centerless grinders, it refers to machines that are designed and built by specialized manufacturers to meet specific industry standards and applications.

Centerless grinding differs from traditional grinding methods in that it does not require the use of a spindle to hold the workpiece. Instead, the workpiece is placed between two grinding wheels, one of which is stationary while the other rotates at a different speed. This unique setup allows for the continuous feeding of parts and results in high throughput rates. The simplicity of the centerless grinding process makes it highly efficient and ideal for mass production of cylindrical parts.

Understanding OEM Centerless Grinders A Key Component in Precision Manufacturing

Another significant benefit of OEM centerless grinders is their ability to handle a wide range of materials, including metals, plastics, and ceramics, making them a versatile choice for many manufacturing environments. With the right machines, manufacturers can achieve not only the desired dimensions but also superior surface finishes, leading to improved performance and longevity of the final products.

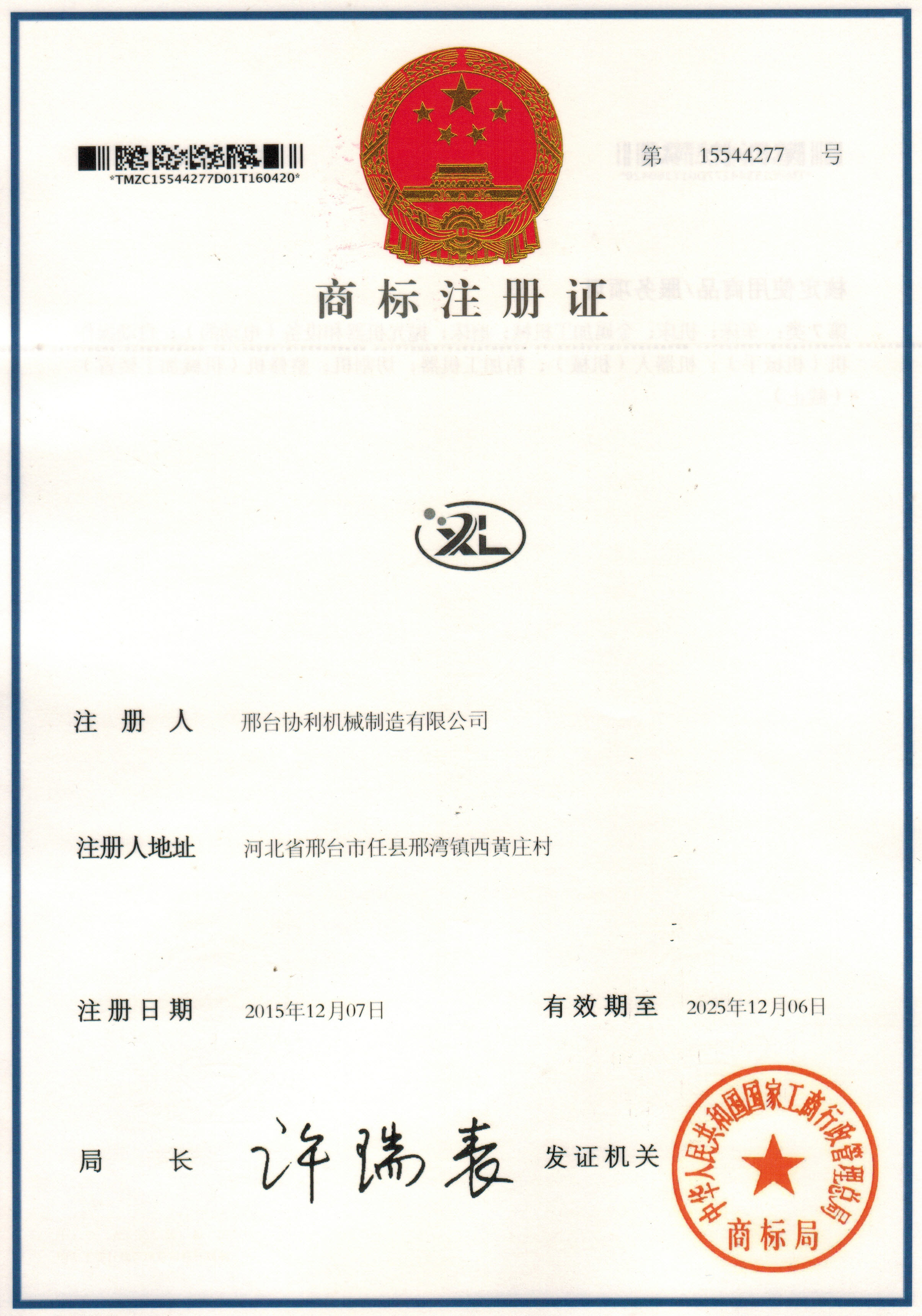

oem centerless grinder

In terms of technology, OEM centerless grinders are continually evolving. Many manufacturers now incorporate advanced features such as CNC (Computer Numerical Control) systems, which allow for increased automation and precision. These modern machines can be programmed to perform complex grinding tasks with minimal human intervention, reducing the chances of error and enhancing productivity through consistent output quality.

Moreover, the integration of smart technologies into OEM centerless grinders is revolutionizing the industry. With real-time monitoring and diagnostic capabilities, manufacturers can achieve better control over their grinding processes, identifying potential issues before they escalate and facilitating predictive maintenance. This approach not only minimizes downtime but also optimizes the overall operational efficiency of the grinding process.

When considering the use of OEM centerless grinders, it is essential for manufacturers to partner with reputable suppliers who offer quality machines backed by good customer support. The investment in these machines represents a commitment to maintaining high production standards and operational excellence.

In conclusion, OEM centerless grinders are fundamental tools within precision manufacturing processes. Their ability to provide customized solutions, adaptability to various materials, and incorporation of advanced technologies make them indispensable. As industries continue to demand tighter tolerances and higher quality finishes, the significance of mastering centerless grinding technology will only grow, positioning OEM centerless grinders as vital assets in competitive manufacturing landscapes.