The Importance of OEM 340-20 Centerless Grinder in Modern Manufacturing

In the realm of precision engineering and manufacturing, the tools and machinery utilized are vital for ensuring high-quality output. One such piece of equipment that has gained prominence is the OEM 340-20 centerless grinder. This machine stands out for its remarkable ability to enhance productivity and efficiency in the manufacturing process, making it an essential asset in various industries.

The centerless grinding process, as facilitated by the OEM 340-20, is distinct due to its unique configuration. Unlike traditional grinding machines that require the part to be held by a chuck or fixture, centerless grinders support the workpiece between two rotating wheels the grinding wheel and the regulating wheel. This design not only streamlines the grinding process but also allows for continuous and efficient production of cylindrical components. Parts can be fed into the machine without the need for extensive setup, significantly reducing downtimes.

The Importance of OEM 340-20 Centerless Grinder in Modern Manufacturing

Moreover, the OEM 340-20 is designed with user-friendliness in mind. Its intuitive controls and setup procedures allow operators to quickly adapt to the machine, enhancing operational efficiency. Additionally, advanced features such as automatic feeding and precision adjustments contribute to smoother workflows and less time spent on the setup. This ease of operation is crucial in a fast-paced manufacturing environment where time is money.

oem 340-20 centerless grinder

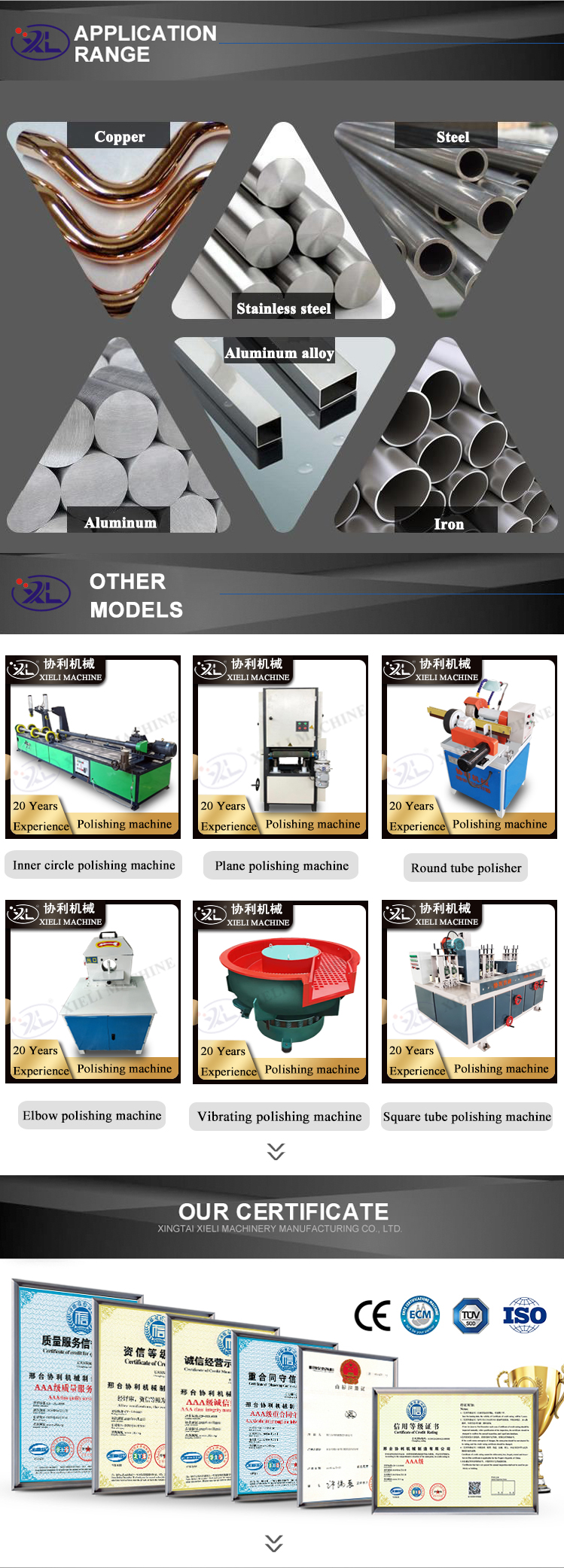

Another notable aspect of the OEM 340-20 is its versatility. The machine can be configured to grind a variety of materials, including metals, plastics, and composites, making it highly adaptable for different applications. Whether it’s producing shafts, tubes, or pins, the centerless grinder can be finely tuned to accommodate diverse specifications, catering to a wide array of industries.

Sustainability is becoming an increasingly important consideration in manufacturing. The OEM 340-20 centerless grinder supports eco-friendly practices by reducing material waste. The efficient grinding process ensures that the maximum amount of material is utilized, minimizing scrap. Additionally, the machine's design incorporates energy-efficient components, contributing to overall energy savings during operation.

Furthermore, maintenance and uptime are critical factors for manufacturers. The OEM 340-20 centerless grinder is built with durability in mind, featuring robust components that require minimal maintenance. Regular service and easy access to parts ensure that machines remain operational, reducing the likelihood of costly downtimes.

In conclusion, the OEM 340-20 centerless grinder plays a vital role in modern manufacturing by providing precision, efficiency, and versatility. Its ability to maintain strict tolerances while enabling rapid production cycles makes it an ideal choice for industries that demand high-quality output. As manufacturing continues to evolve, tools such as the OEM 340-20 will undoubtedly remain integral in driving productivity and supporting sustainable practices. Embracing such advanced machinery not only enhances operational capabilities but also positions businesses to meet the challenges of an ever-competitive marketplace.