Exploring the Benefits of Centerless Grinding Technology in Taiwan

In the realm of precision manufacturing, centerless grinding has emerged as a pivotal technique, particularly for industries demanding high accuracy and efficient production. Taiwan, known for its robust manufacturing sector, has increasingly embraced this technology through innovation and expertise. This article delves into the significance and advantages of centerless grinding, especially as it pertains to the manufacturing landscape in Taiwan.

What is Centerless Grinding?

Centerless grinding is a method that involves the grinding of external cylindrical surfaces without needing a centering device. Unlike traditional cylindrical grinding where the workpiece is placed between centers, centerless grinding uses a regulating wheel to control the workpiece's rotation and position. This process allows for rapid removal of material, producing components with high precision, minimal deflection, and superior surface finishes.

Advantages of Centerless Grinding

1. Increased Efficiency One of the primary advantages of centerless grinding is its ability to produce parts with high efficiency. The continuous production process reduces cycle time significantly compared to centering methods. This aspect is crucial for Taiwanese manufacturers that focus on maximizing output while minimizing production costs.

2. Improved Accuracy Centerless grinding provides exceptional dimensional accuracy. The absence of centering devices reduces potential errors, enabling manufacturers to produce parts with tight tolerances. This precision is essential in industries such as automotive, aerospace, and electronics, where even minor discrepancies can lead to significant functional issues.

3. Flexibility in Production Taiwan's manufacturing sector is characterized by its diversity, producing everything from small intricate components to large structural parts. Centerless grinding machines can adapt to various sizes and shapes, making them ideal for custom jobs and mass production alike. This flexibility supports the island's reputation for being a hub for both custom and volume manufacturing.

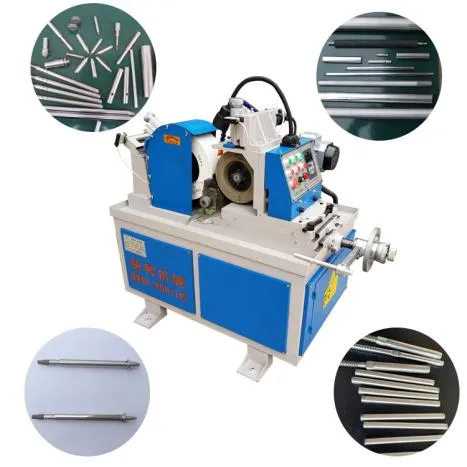

odm taiwan centerless grinder

4. Enhanced Surface Finish The grinding process is capable of achieving high-quality surface finishes, which is a critical requirement in many applications. A well-ground surface can enhance the performance and longevity of components, reducing the need for additional finishing operations, thereby saving time and costs.

Technological Advancements in Taiwan

Taiwan has made significant strides in the development of centerless grinding technology. Local companies are investing in advanced machinery and enhanced grinding techniques that incorporate automation and smart technology. These advancements not only optimize processes but also facilitate better control over quality and consistency.

Furthermore, Taiwanese manufacturers are heavily focused on research and development, giving them an edge in producing innovative grinding solutions tailored for specific industry needs. Collaborations with academic institutions have led to the exploration of new materials and techniques that are setting benchmarks in the field of precision grinding.

The Future of Centerless Grinding in Taiwan

As the global market becomes more competitive, Taiwan's ongoing commitment to improving manufacturing processes positions it favorably for the future. The rise of Industry 4.0 and the integration of artificial intelligence and the Internet of Things (IoT) into manufacturing are set to enhance centerless grinding operations even further. These technologies promise to optimize workflow, predict maintenance needs, and ensure high precision, thus solidifying Taiwan’s role as a leader in precision manufacturing.

Conclusion

In conclusion, centerless grinding is a cornerstone of Taiwan's manufacturing prowess. Through its numerous advantages—efficiency, accuracy, flexibility, and enhanced surface finish—this machining method supports a wide array of industries. With continuous technological advancements and a commitment to quality, Taiwan is poised to remain at the forefront of centerless grinding, meeting the evolving demands of the global market and setting standards for precision engineering. The future remains bright for this essential facet of Taiwanese manufacturing, ensuring that it continues to thrive in an ever-changing landscape.