The Importance of ODM Aluminium Tube Polishing Machines in Modern Industry

In today's fast-paced manufacturing landscape, the quest for excellence in surface finish is more critical than ever. As industries continue to innovate and push the boundaries of engineering, aluminium tube polishing machines have emerged as vital tools for enhancing both aesthetics and performance of products. Furthermore, Original Design Manufacturer (ODM) aluminium tube polishing machines have gained prominence due to their ability to provide customized solutions tailored to specific industrial needs.

Understanding ODM Aluminium Tube Polishing Machines

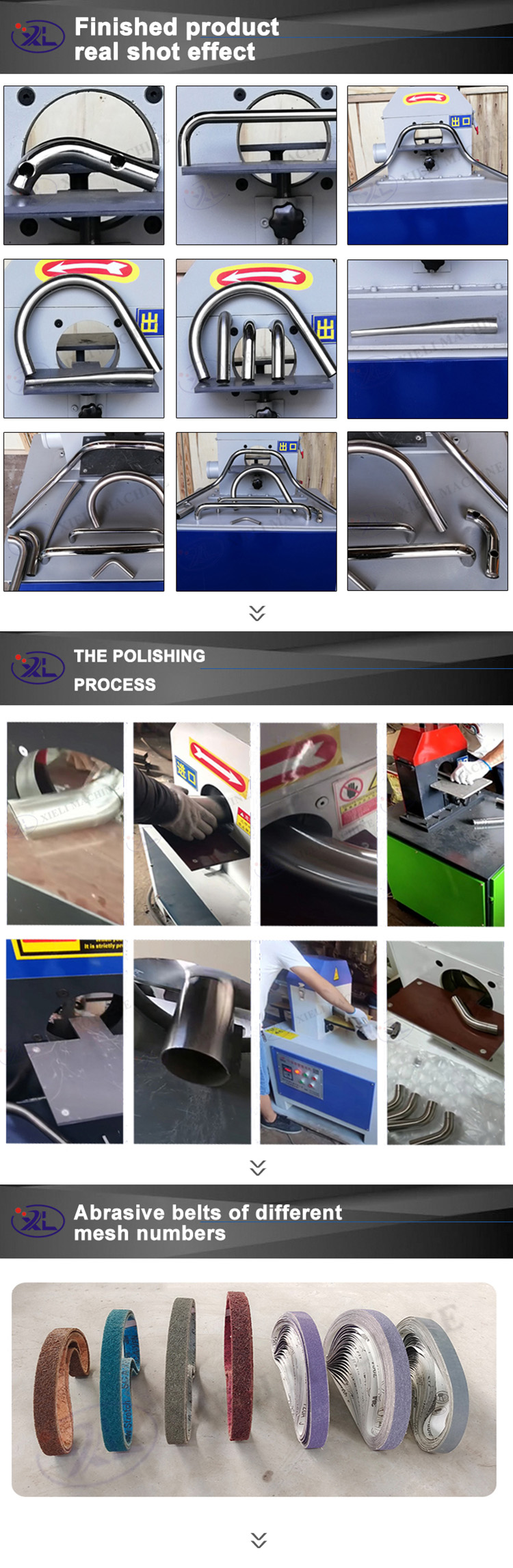

An ODM aluminium tube polishing machine is specifically designed to prepare and finish aluminium tubes, ensuring that they exhibit a high-quality surface finish. These machines use advanced polishing techniques, often incorporating a combination of mechanical and chemical processes. This results in tubes that not only look polished but also possess improved corrosion resistance, durability, and overall performance.

The significance of an ODM approach lies in the customizability it offers. Manufacturers can collaborate with ODM providers to design and produce polishing machines tailored to their unique specifications. This bespoke service ensures that the polishing process aligns perfectly with production requirements, optimizing efficiency and output.

Benefits of Aluminium Tube Polishing

Polishing aluminium tubes serves multiple purposes, offering numerous advantages across various industries. The most apparent benefit is aesthetic enhancement; polished aluminium surfaces are visually appealing and often required for consumer-facing products. In industries like automotive, aerospace, and architecture, the visual aspects of aluminium components can significantly influence customer perceptions and marketability.

Beyond aesthetics, polishing also serves functional purposes. A smooth surface reduces friction, which is crucial in applications where tubes are part of mechanical systems. By minimizing the surface roughness, manufacturers can ensure that their products adhere to precise specifications, thereby preventing potential failures due to friction. Furthermore, polished aluminium is less prone to contamination and easier to clean, making it ideal for industries such as food processing and pharmaceuticals.

odm aluminium tube polishing machine

Advancements in Technology

The evolution of polishing technology has significantly enhanced the capabilities of ODM aluminium tube polishing machines. Automation and robotics have become integral components of modern polishing machines, allowing for higher precision and consistency. Automated systems can process multiple tubes simultaneously, increasing throughput while maintaining uniformity across batches.

Additionally, the integration of computer numerical control (CNC) technology has transformed the manufacturing process. Operators can input specific polishing parameters, ensuring that each tube is polished according to exact specifications. This leads to reduced waste and enhanced quality control, ultimately benefiting manufacturers who prioritize efficiency and product excellence.

The Role of Sustainability

As industries face increasing pressure to adopt sustainable practices, the role of polishing machines adapts accordingly. Many ODM polishing equipment manufacturers are now focusing on eco-friendly processes that minimize waste and energy consumption. For instance, using biodegradable polishing compounds and energy-efficient machinery can significantly reduce the environmental footprint of the polishing operation.

Moreover, advanced filtration systems in modern polishing machines ensure that waste materials are recyclable or safely disposed of, aligning with the global push towards sustainability. By implementing these practices, manufacturers not only adhere to regulatory standards but also demonstrate corporate responsibility, appealing to environmentally conscious consumers.

Conclusion

In conclusion, ODM aluminium tube polishing machines are indispensable in manufacturing settings where surface finish quality is paramount. By offering customizable solutions, these machines enhance both aesthetic and functional properties of aluminium tubes, contributing to overall product excellence. With advancements in technology and an increasing focus on sustainability, the future of aluminium tube polishing looks promising. As industries continue to evolve, so too will the tools that enable them to achieve remarkable standards in quality and performance.