Lidköping Centerless Grinding Machines A Marvel of Precision Engineering

Lidköping, a city renowned for its engineering prowess, has made significant contributions to the field of manufacturing, particularly in the realm of centerless grinding machines. These machines play a vital role in the production processes of various industries, offering unparalleled precision and efficiency for grinding cylindrical objects.

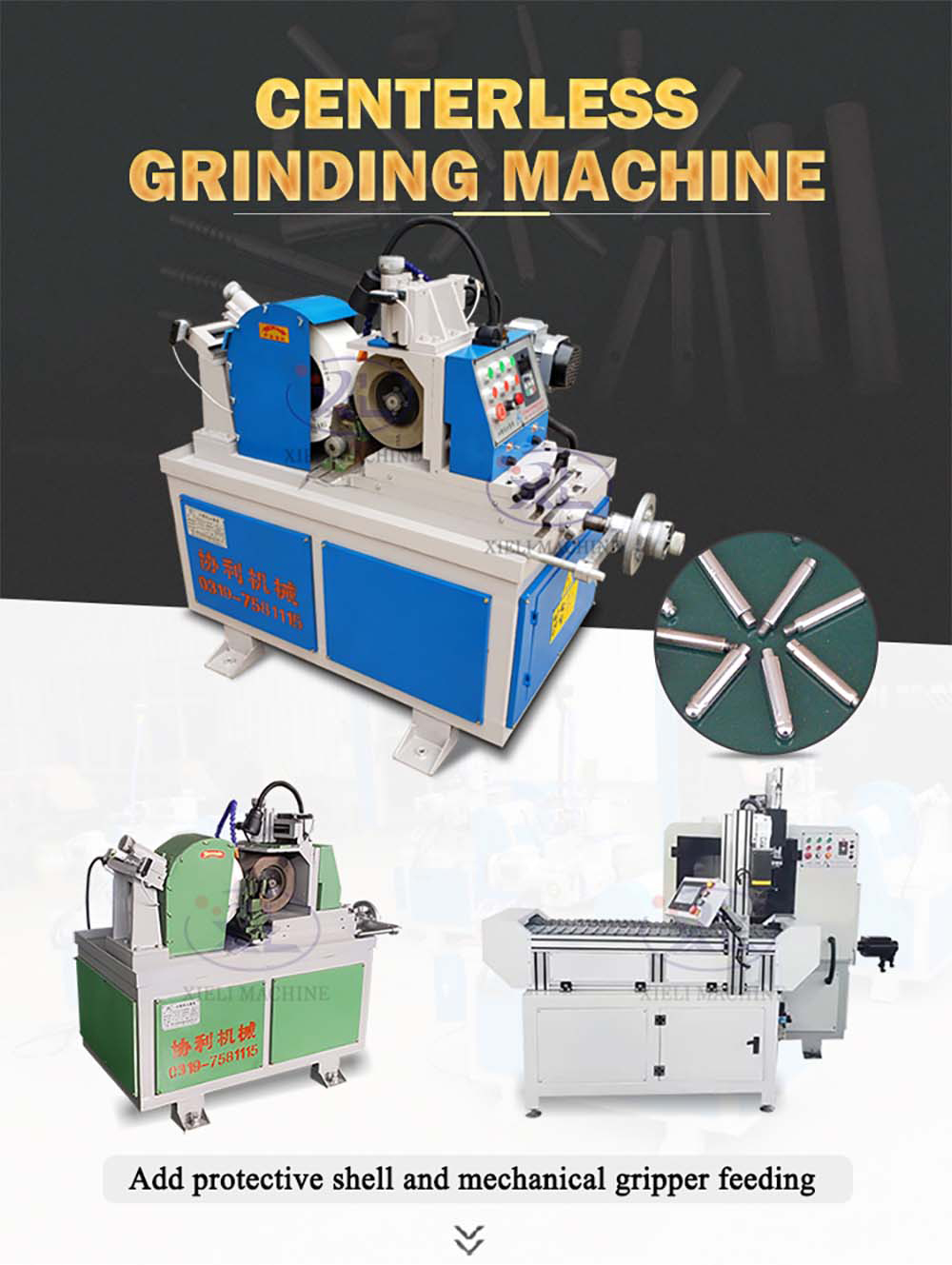

At the heart of Lidköping's innovation lies the centerless grinding machine, a specialized type of equipment that allows for the grinding of parts without the need for a central axis. This method enables the simultaneous grinding of multiple workpieces, resulting in high productivity and exceptional surface finishes. In an era where precision is paramount, Lidköping’s centerless grinding machines stand out for their ability to achieve tolerances of just a few microns.

The Lidköping factories are equipped with advanced technology that enhances both the performance and reliability of these machines. From high-speed spindles to sophisticated control systems, every aspect of the design is optimized for efficiency. These machines can accommodate a wide range of materials, including metals, plastics, and composites, making them versatile tools across various sectors such as automotive, aerospace, and medical device manufacturing.

lidkoping centerless grinding machine factories

One of the key advantages of centerless grinding is its ability to handle long and slender workpieces, which are often difficult to grind using traditional methods. With Lidköping centerless grinders, manufacturers can process parts that would otherwise require multiple setups, leading to reduced cycle times and lower production costs.

Moreover, the commitment to continuous improvement and innovation is evident in the Lidköping factories. Engineers are constantly refining the grinding process by integrating cutting-edge technologies such as automation and data analytics. This focus on smart manufacturing not only boosts productivity but also enhances quality control, ensuring that each component meets the rigorous standards demanded by today’s industries.

In conclusion, Lidköping's centerless grinding machines exemplify the intersection of precision engineering and innovative manufacturing. As industries evolve and the demand for high-quality components increases, Lidköping remains at the forefront, delivering superior grinding solutions that empower manufacturers worldwide. The legacy of excellence in centerless grinding that originated in this city continues to set the standard for quality and efficiency, making Lidköping a name synonymous with reliability in precision machining.