Exploring the Landis Viking Centerless Grinder A Leader in Precision Engineering

In the world of precision machining, centerless grinding stands out as a vital process for producing components with highly accurate dimensions and excellent surface finishes. Among the myriad of centerless grinder manufacturers, Landis has carved a niche for itself, particularly with its Viking series of centerless grinders. These machines are renowned for their exceptional performance, reliability, and versatility, making them a preferred choice for manufacturers across various industries.

The Landis Viking Centerless Grinder is designed to handle the grinding of a wide range of parts, from small components to larger workpieces, with ease and efficiency. One of the distinguishing features of the Viking series is its ability to grind multiple diameters and complex shapes without the need for extensive setups. This capability significantly reduces downtime and enhances productivity, making it an attractive option for manufacturers seeking to optimize their operations.

At the heart of the Landis Viking is its innovative design, which includes advanced features that improve both accuracy and speed. The grinder employs a precise grinding wheel technology that ensures consistent results, while its robust construction provides the necessary stability for high-precision applications. The machine’s versatility is further enhanced by its adaptability to various materials, including metals, plastics, and composites, catering to the diverse needs of different industries.

One of the key advantages of the Landis Viking Centerless Grinder is its user-friendly interface. Operators can easily program and control the machine, allowing for quick adjustments and minimizing the learning curve for new users. This ease of operation, combined with the machine's reliability, means that even high-volume production runs can be managed smoothly and efficiently.

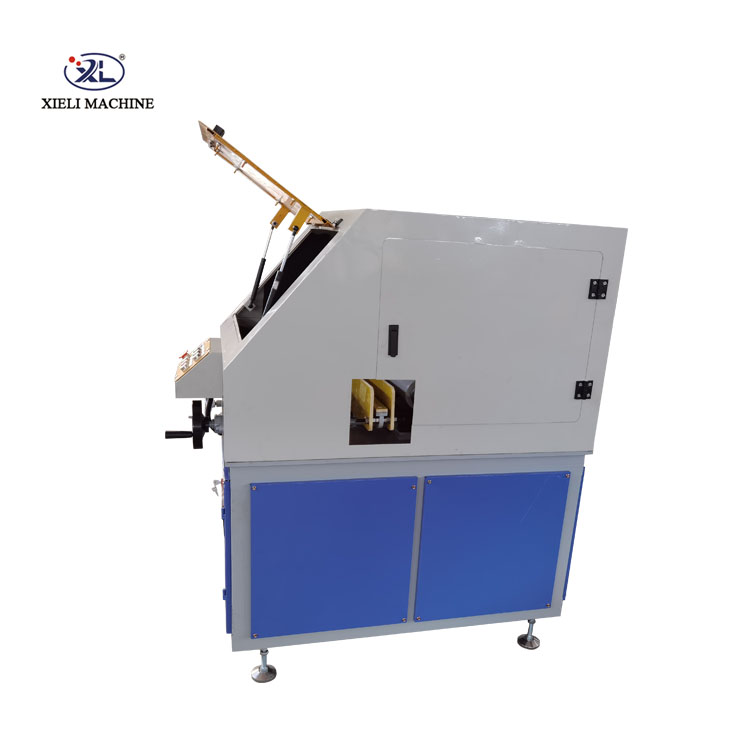

landis viking centerless grinder manufacturer

In terms of maintenance, the Landis Viking series is designed with accessibility in mind. Components are arranged for easy access, which simplifies routine maintenance tasks and contributes to the machine’s longevity. This thoughtful design reduces overall operational costs, as well-maintained machines tend to have longer lifespans and require less frequent repairs.

Moreover, Landis stands out in the industry for its commitment to customer support. The company provides comprehensive service solutions, including installation, training, and ongoing technical support. This dedication ensures that customers can maximize the performance of their Landis Viking grinders, further enhancing their productivity and competitiveness in the market.

The growing demand for precision-engineered components has made the Landis Viking Centerless Grinder an increasingly popular choice. Industries such as automotive, aerospace, and medical have recognized the importance of investing in high-precision grinding technologies to meet stringent quality standards. As manufacturers strive to keep up with rapid advancements in technology and increasing consumer expectations, the Landis Viking equips them with the necessary tools to stay ahead.

In conclusion, the Landis Viking Centerless Grinder encapsulates the essence of precision engineering, combining innovative design, user-friendly operation, and robust performance. Its ability to deliver exceptional results across a variety of applications makes it a valuable asset for manufacturers aiming to achieve superior accuracy and efficiency. As industries continue to evolve, the Landis Viking is poised to remain a key player in the landscape of machining technologies, driving innovations and supporting manufacturers in their quest for excellence.