Understanding the Importance of KEF Centerless Grinders A Comprehensive Guide

In the realm of precision manufacturing, centerless grinders play an essential role in achieving high levels of accuracy and efficiency. Among the leading names in this field is KEF, a manufacturer renowned for its innovative and reliable centerless grinding solutions. This article explores the significance of KEF centerless grinders, delving into their features, benefits, and the broader implications for manufacturing.

The Mechanics of Centerless Grinding

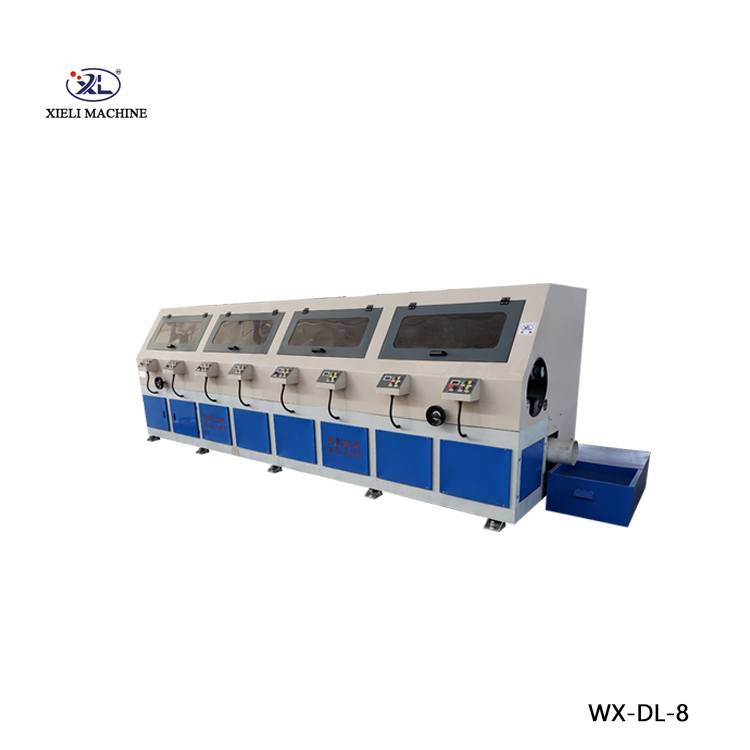

Centerless grinding is a method used for producing round workpieces without the need for a spindle. In this process, the workpiece is placed between two grinding wheels, one of which is stationary while the other is adjustable. The absence of a spindle allows for increased production speeds and the ability to grind multiple pieces simultaneously.

The KEF centerless grinders are designed with a well-engineered setup that ensures stability and precision. They are equipped with advanced features that allow for optimal grinding efficiency and reduced cycle times. This makes them ideal for industries where high throughput and stringent tolerances are critical, such as automotive, aerospace, and medical device manufacturing.

Features of KEF Centerless Grinders

KEF's approach to centerless grinding emphasizes user-friendly design and cutting-edge technology. Some notable features include

1. Precision Grinding Wheels KEF grinders utilize top-quality diamond or CBN (cubic boron nitride) wheels that enhance grinding efficiency and prolong the life of the equipment.

2. Adjustable Components The machines offer adjustable height and angles to accommodate varying workpiece sizes and shapes. This flexibility is vital for businesses that require customization in their manufacturing processes.

3. Automated Controls Modern KEF grinders come with user-friendly interfaces and automated controls that simplify the grinding process. Operators can quickly set parameters and monitor performance in real-time, leading to significant time savings.

kef centerless grinder quotes

4. Robust Build Quality KEF centerless grinders are built to withstand the rigors of continuous operation. The materials and construction techniques used ensure durability and reduce maintenance needs over time.

5. Enhanced Safety Features Keeping workers safe is a top priority. KEF equips its grinders with multiple safety features, including emergency stop buttons, protective guards, and system diagnostics that alert operators to potential issues.

Benefits of Using KEF Centerless Grinders

Organizations leveraging KEF centerless grinders can expect several benefits

- Improved Productivity The speed and efficiency of precision grinding operations translate into higher output rates, enabling businesses to meet demand without sacrificing quality. - High Precision With the ability to achieve tight tolerances, KEF grinders ensure that workpieces meet the stringent specifications required in high-stakes industries.

- Cost-Effectiveness By optimizing the grinding process and minimizing tool wear, KEF grinders can lead to reduced operating costs, providing long-term savings for manufacturers.

- Versatility KEF machines can handle a wide range of materials, including metals and plastics, making them suitable for various applications across multiple industries.

- Ease of Operation The intuitive designs minimize the learning curve for new operators, ensuring that businesses can maintain consistent production levels even in high-turnover environments.

Conclusion

In conclusion, KEF centerless grinders stand out as a vital tool in modern manufacturing practices. Their advanced features, reliability, and ability to deliver precise results have made them a preferred choice for businesses looking to enhance their grinding operations. As industries continue to evolve, the demand for high-quality, efficient machinery will grow, cementing KEF's role as a key player in the field of precision grinding. Embracing these machines not only elevates manufacturing capabilities but also sets the foundation for innovation and growth in competitive markets. Whether you're a small manufacturer or a large-scale operation, investing in KEF centerless grinders can pave the way for improved efficiency and product quality.