High-Quality Centerless Grinding Machine Parts

Centerless grinding is a vital machining process used in manufacturing to achieve precise dimensions and superior surface finishes on cylindrical parts. The efficiency and effectiveness of this process largely depend on the quality of the grinding machine itself, specifically its components. The production of high-quality centerless grinding machine parts is essential for maximizing the performance and reliability of these machines.

Centerless grinding operates without the need for a spindle to hold the workpiece. Instead, the workpiece is supported by a regulating wheel and a grinding wheel. To ensure optimal functionality, the components involved must be manufactured to exacting standards. These parts include the grinding wheel, regulating wheel, bearings, and other critical elements that influence the machine’s performance.

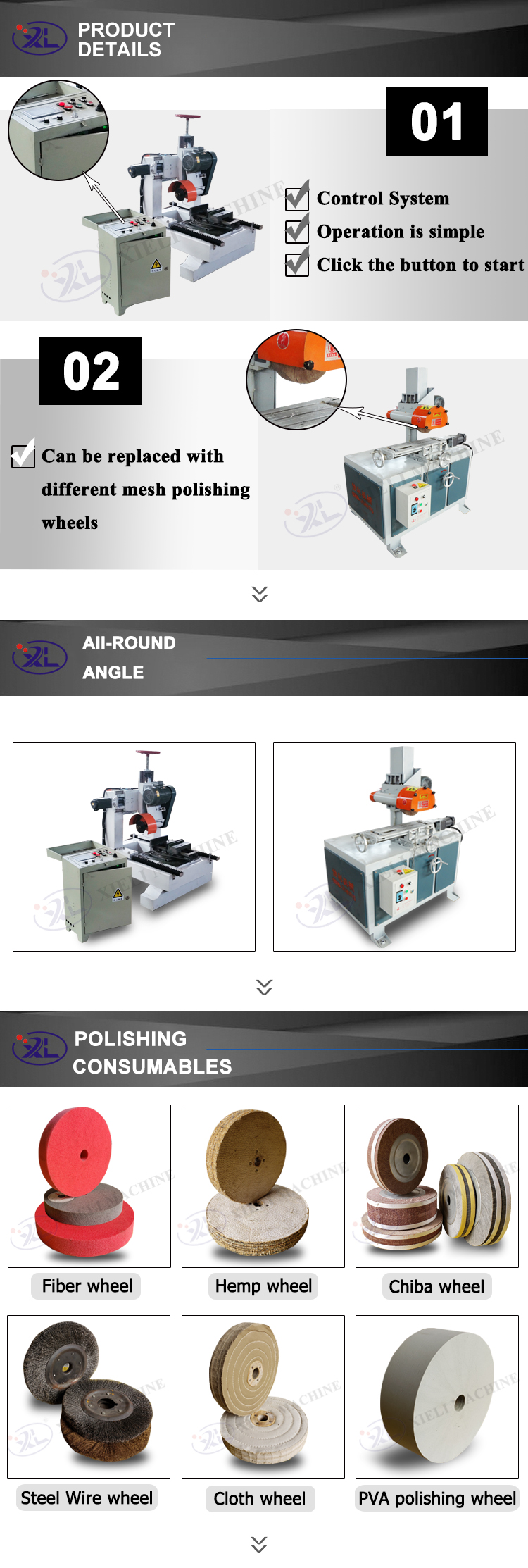

High-quality grinding wheels are particularly important, as they determine the grinding efficiency and surface finish of the workpiece. Made from a variety of abrasives, these wheels must be engineered to withstand heavy loads and provide consistent grinding action over time. The material selection, bonding agent, and wheel geometry all play crucial roles in ensuring that the grinding wheels meet the specific requirements of different applications.

high quality centerless grinding machine parts

Another key component is the regulating wheel. This wheel’s diameter, hardness, and surface finish directly affect the speed and stability of the workpiece as it is fed into the grinding zone. Precision in the manufacturing of these wheels ensures that they maintain a constant speed and pressure, which is critical for achieving uniform results.

Bearings and shafts are equally significant, as they support the rotating components of the machine. High-quality bearings reduce friction and wear, leading to smoother operation and longer machine life. Additionally, precise machining of shafts ensures perfect alignment and minimal vibration during operation.

To maintain a competitive edge in the manufacturing industry, companies must prioritize sourcing or producing high-quality centerless grinding machine parts. Implementing stringent quality control measures and utilizing advanced manufacturing techniques can significantly enhance the durability and efficiency of these machines.

In conclusion, the importance of high-quality centerless grinding machine parts cannot be overstated. By ensuring that every component is manufactured to the highest standards, manufacturers can achieve better performance, increased productivity, and enhanced longevity of their grinding machines. This commitment to quality ultimately leads to superior products and satisfied customers in the dynamic landscape of modern manufacturing.