The High-Quality Centerless Grinder Market An Overview

The centerless grinder has become an essential tool in the manufacturing sector, particularly for industries that require precision and efficiency in machining processes. As global demand for high-quality components rises, the centerless grinder market is poised for significant growth. This article explores the current trends, challenges, and opportunities within this niche, high-quality segment of the machinery market.

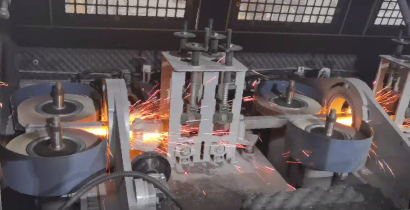

Centerless grinding is a machining process that allows for the efficient grinding of cylindrical parts without the need for a spindle. Unlike traditional grinding methods, this technique offers several advantages, including faster production rates, reduced cycle times, and the ability to handle complex part geometries. These benefits have made centerless grinders an indispensable asset in industries such as automotive, aerospace, and medical device manufacturing.

One of the driving forces behind the high-quality centerless grinder market is the increasing demand for precision-engineered components. As industries push for tighter tolerances and improved surface finishes, manufacturers are investing in advanced grinding technology to meet these requirements. High-quality centerless grinders equipped with the latest automation and control systems enable manufacturers to achieve higher levels of productivity and reduce waste, making them a worthy investment.

high quality centerless grinder market

However, the market is not without its challenges. The high initial cost of premium centerless grinding machines can be a significant barrier for small to medium-sized enterprises. Furthermore, skilled labor shortages and the need for regular maintenance can add to operational costs. Manufacturers must navigate these challenges while continuing to innovate and improve their product offerings.

Opportunities abound for companies that focus on developing cutting-edge technologies. The integration of Industry 4.0 principles, such as IoT and real-time data analytics, into centerless grinder operations can enhance machine performance and predictive maintenance. These advancements can lead to considerable cost savings and greater operational efficiency.

In conclusion, the high-quality centerless grinder market is experiencing robust growth driven by increasing demand for precision and efficiency in manufacturing. While challenges exist, the opportunities for innovation and technological advancement present a compelling case for investment in this sector. As industries continue to evolve, the centerless grinder will undoubtedly remain a critical component in the pursuit of manufacturing excellence.