Advancing Surface Finish: The Evolution of Round Tube Polishing Technology

In the competitive landscape of modern manufacturing, the surface quality of tubular components is not merely an aesthetic consideration but a critical factor influencing functionality, longevity, and adherence to stringent industry standards. From petrochemical pipelines requiring immaculate internal and external finishes for corrosion resistance, to medical instruments demanding ultra-smooth surfaces for sterilization and biocompatibility, the demand for high-precision tube polishing has never been greater. This article delves into the intricacies of the round tube polishing machine, exploring its technical prowess, diverse applications, and the strategic advantages it offers.

Industry trends indicate a significant shift towards automation, enhanced efficiency, and greater precision in surface finishing processes. Manufacturers are increasingly seeking solutions that not only deliver superior surface roughness (Ra) values but also reduce operational costs, minimize material waste, and integrate seamlessly into existing production lines. The focus is on robust, reliable machinery capable of handling a variety of materials and dimensions, while maintaining consistent output quality at high throughputs. This demand drives innovation, pushing the boundaries of machine design and control systems to meet the evolving needs of advanced manufacturing sectors.

Furthermore, the global emphasis on sustainability and energy efficiency also influences the design of modern polishing machines. Innovations aim to reduce energy consumption, optimize abrasive usage, and implement closed-loop coolant systems, making the process more environmentally responsible. The pursuit of the best round tube polishing machine often involves a careful balance between performance, cost-effectiveness, and ecological footprint.

The Advanced Manufacturing and Operational Flow of a Round Tube Polishing Machine

Machine Construction: Ensuring Durability and Precision

The construction of a high-performance round tube polishing machine is a testament to precision engineering, designed to withstand rigorous industrial environments while delivering consistent, high-quality finishes. Key product materials often include high-grade structural steel alloys (e.g., Q235B, S355JR) for the main frame, providing a stable, vibration-dampening foundation. Critical components such as polishing heads, spindles, and guide rollers are typically fabricated from hardened tool steel or precision-machined aluminum alloys, ensuring dimensional stability and wear resistance.

The manufacturing processes for these machines involve several sophisticated steps:

- Casting and Forging: Heavy-duty bases and foundational elements, crucial for stability and minimizing operational vibration, are often produced via casting (e.g., grey cast iron) or forging, ensuring exceptional material density and strength.

- CNC Machining: Precision is paramount. Components like polishing head mounts, gearboxes, and roller guides undergo multi-axis CNC machining to achieve micron-level tolerances, which directly impacts polishing uniformity and repeatability.

- Robotic Welding: Structural frames are assembled using advanced robotic welding techniques, ensuring strong, consistent welds that prevent deformation and enhance the machine's overall rigidity and service life.

- Surface Treatment: After fabrication, components are often sandblasted, primed, and powder-coated or painted with industrial-grade epoxies. This enhances corrosion resistance, protects against harsh workshop conditions, and contributes to the machine's aesthetic appeal.

Operational Flow: From Raw Tube to Polished Finish

The operational process of a round tube polishing machine is highly streamlined and typically follows these stages, designed for maximum efficiency and superior surface quality:

- Tube Loading: Tubes are automatically or manually loaded onto an infeed conveyor system, ensuring stable and sequential feeding.

- Feeding Mechanism: Precision roller systems or belt feeders guide the tube through the polishing stations at a controlled speed, often adjustable via electric buttons for optimal material removal.

- Multi-Stage Polishing: The tube passes through several polishing heads, each equipped with different abrasive media (e.g., abrasive belts, sisal wheels, cloth wheels) and grits, progressing from coarser to finer finishes. Each head operates independently with adjustable pressure and rotation speed.

- Cooling & Lubrication: A constant flow of coolant/lubricant minimizes heat buildup, prevents material deformation, extends abrasive life, and facilitates swarf removal.

- Cleaning & Drying: Post-polishing, tubes may undergo a cleaning station (e.g., high-pressure wash, ultrasonic cleaning) to remove residual abrasive particles and a drying stage to prepare them for subsequent processes or packaging.

- Unloading: Finished tubes are discharged onto an outfeed conveyor or collection rack.

Testing Standards and Service Life

All critical components and the assembled machine undergo rigorous testing to ensure compliance with international standards. This includes ISO 9001 for quality management systems, CE marking for European market conformity, and specific mechanical testing standards (e.g., ASTM, ANSI) for material strength and dimensional accuracy. Advanced diagnostic tools are employed to verify motor performance, alignment, vibration levels, and control system integrity before dispatch. With proper maintenance, the service life of these robust machines typically exceeds 15-20 years, offering a significant return on investment.

Advantages in Key Application Scenarios

In industries like petrochemical and water supply & drainage, the uniform, high-quality finish achieved by a round tube polishing machine is vital. It significantly reduces surface imperfections, thereby increasing resistance to corrosion and scaling, and improving fluid flow dynamics. For metallurgy, the aesthetic appeal and reduced surface friction are paramount. These machines often feature energy-efficient motors and optimized abrasive systems, leading to substantial energy savings compared to older, less efficient models. The superior surface finish also translates to enhanced product durability and compliance with strict industry-specific regulations.

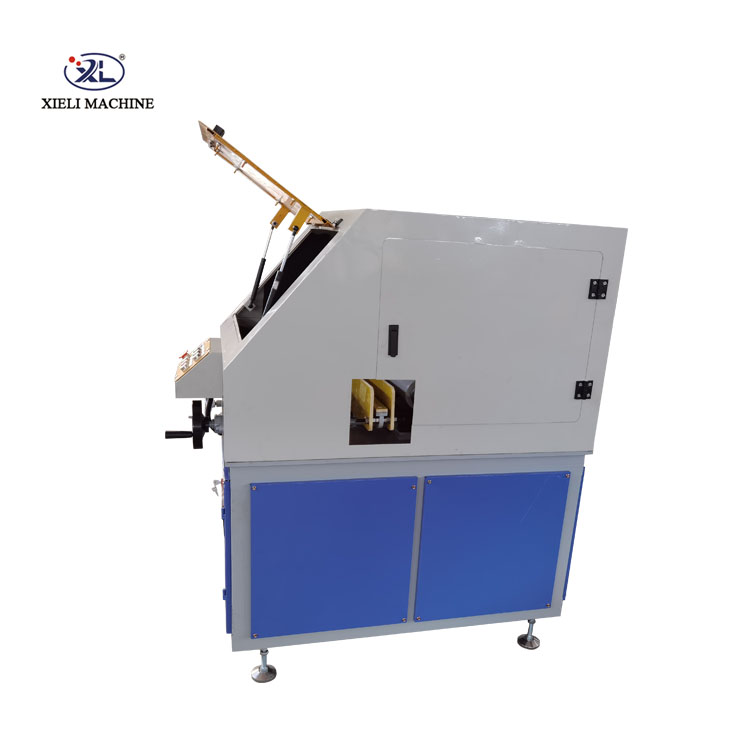

Precision engineering ensuring a seamless polishing process.

Key Technical Specifications: Electric Button Adjustable Round Steel Tube Polishing Machine

The "Electric button to adjust the round steel tube polishing machine" represents a significant advancement in automated surface finishing. Its intuitive control system allows for quick and precise adjustments, crucial for handling diverse tube specifications and achieving exacting surface finish requirements. Below is a detailed table outlining typical technical specifications that define the capabilities of such a sophisticated machine.

| Parameter | Specification |

|---|---|

| Polishing Diameter Range | Ø10mm - Ø150mm (Customizable to Ø200mm) |

| Polishing Length | Minimum 500mm, Unlimited (Pass-through design) |

| Main Motor Power | 3 kW - 7.5 kW per polishing head (Variable) |

| Number of Polishing Heads | 2 to 10 stations (Modular, customizable) |

| Polishing Wheel Speed | 1450 - 2800 RPM (Variable Frequency Drive controlled) |

| Feeding Speed | 0.5 - 6 meters/minute (Adjustable via electric button) |

| Surface Roughness Achieved | Ra 0.8 µm down to Ra 0.05 µm (depending on material & grit sequence) |

| Control System | PLC with HMI Touch Screen & Electric Button Interface |

| Power Requirements | 3 Phase, 380V/50Hz (Customizable to regional standards) |

| Dimensions (L x W x H) | Varies with number of heads (e.g., 6m x 1.2m x 1.8m for 6 heads) |

| Approx. Weight | 2,500 kg - 8,000 kg (Depending on configuration) |

| Dust Collection System | Integrated (optional) with filtration efficiency > 99% |

Note: Specifications may vary based on specific model and customization requirements.

Diverse Application Scenarios Across Industries

The versatility of the round tube polishing machine makes it an indispensable asset across a multitude of industries, each with unique surface finish requirements. Its ability to process various materials and achieve a wide range of Ra values positions it at the forefront of surface engineering solutions.

- Petrochemical and Oil & Gas: Tubes used in heat exchangers, pipelines, and hydraulic systems require impeccable internal and external finishes. This is critical for preventing material accumulation, minimizing fluid friction, and enhancing resistance to corrosive agents and stress corrosion cracking, thereby extending the operational life of vital infrastructure.

- Medical and Pharmaceutical: For surgical instruments, prosthetic components, and pharmaceutical piping, a sterile, highly polished surface is non-negotiable. The ultra-smooth finish achieved by advanced polishing machines inhibits bacterial growth, facilitates thorough cleaning, and ensures biocompatibility, meeting stringent regulatory demands (e.g., FDA, GMP).

- Automotive and Aerospace: Components like exhaust systems, hydraulic lines, engine parts, and structural elements demand precise surface finishes for both functional performance and aesthetic appeal. In aerospace, polishing titanium or specialty alloys ensures structural integrity, reduces fatigue points, and meets rigorous safety standards.

- Construction and Architectural: Stainless steel handrails, decorative pillars, and structural tubing in modern architecture benefit immensely from a mirror-like or satin finish. This not only enhances visual appeal but also provides increased resistance to environmental elements and simplifies maintenance.

- Food & Beverage Processing: Stainless steel tubing used in breweries, dairies, and other food processing plants requires a hygienically polished surface to prevent product contamination and ensure easy, effective cleaning, adhering to EHEDG guidelines.

Versatility in polishing various tube dimensions and materials.

Technical Advantages and Performance Excellence

Modern round tube polishing machine integrate cutting-edge technology to deliver unparalleled performance, addressing the complex demands of industrial surface finishing. These advantages translate directly into operational efficiencies, cost savings, and superior product quality.

- Exceptional Precision and Uniformity: Advanced control systems, often featuring PLC and HMI interfaces with electric button adjustments, ensure precise control over polishing pressure, speed, and feeding rate. This guarantees a remarkably uniform surface finish along the entire length of the tube, eliminating inconsistencies and defects.

- High Degree of Automation: From automatic tube feeding and multi-station polishing to integrated cleaning and drying, these machines minimize manual intervention. This reduces labor costs, increases throughput, and enhances workplace safety by limiting exposure to moving parts and abrasive dust.

- Material Versatility: Engineered to handle a wide array of materials including stainless steel (304, 316L), carbon steel, aluminum, copper, brass, titanium, and various alloys. The flexibility in abrasive selection and machine settings allows for optimal processing of each material type.

- Enhanced Efficiency and Productivity: Multi-head configurations and optimized abrasive changeover mechanisms drastically cut down processing times. Continuous pass-through designs eliminate loading/unloading bottlenecks, enabling higher production volumes and shorter lead times.

- Durability and Low Maintenance: Constructed with robust, high-quality components, including heavy-duty bearings, wear-resistant guides, and industrial-grade motors, these machines are built for continuous operation with minimal downtime. Predictive maintenance features and easy access for servicing further reduce operational costs.

- Superior Surface Finish Quality: Capable of achieving mirror-like finishes (Ra values as low as 0.05 µm), which are critical for applications requiring extreme hygiene, reduced friction, or premium aesthetic appeal.

- Safety Features: Comprehensive safety interlocks, emergency stop buttons, and fully enclosed polishing zones protect operators and comply with international safety regulations.

Vendor Comparison and Strategic Partnership Selection

Selecting the right supplier for a round tube polishing machine is a strategic decision that impacts long-term operational efficiency and product quality. Beyond initial purchase price, B2B decision-makers must evaluate several critical factors to ensure a successful partnership, especially when considering an oem round tube polishing machine solution.

Key evaluation criteria include:

- Quality and Certifications: Look for vendors with ISO 9001 certification, CE compliance (for European markets), and adherence to relevant industry standards (e.g., ASTM, ANSI). These indicate a commitment to quality manufacturing and product safety.

- Customization Capabilities: Can the vendor tailor the machine to your specific tube dimensions, material types, required Ra values, and production line integration needs? An effective OEM partner will offer flexible design and engineering support.

- After-Sales Support & Service: Evaluate the availability of installation assistance, operator training, technical support (online, phone, on-site), spare parts inventory, and maintenance programs. A robust support network is crucial for minimizing downtime.

- Technological Innovation: Assess the vendor's R&D investment. Are they incorporating the latest advancements in automation, control systems, and abrasive technologies? Innovation ensures your machine remains competitive and efficient.

- Experience and Reputation: A proven track record, positive customer testimonials, and a strong presence in the industry speak volumes about a vendor's reliability and expertise. Look for companies with years of specialized experience in tube polishing solutions.

- Total Cost of Ownership (TCO): Consider not just the purchase price, but also energy consumption, abrasive media costs, maintenance requirements, and anticipated service life. A higher initial investment in a quality machine can lead to lower TCO over time.

Dedicated customer service and technical support are paramount.

Product Comparison: Standard vs. Advanced Polishing Machines

To highlight the advantages of advanced systems, let's compare a generic standard polishing machine with a modern, electric button adjustable system, such as our Electric button to adjust the round steel tube polishing machine.

| Feature | Standard Polishing Machine | Advanced Electric Button Adjustable Polishing Machine |

|---|---|---|

| Automation Level | Manual or semi-automatic tube feeding and adjustments. | Full automation with electric button adjustments, PLC/HMI control. |

| Precision & Repeatability | Moderate, depends heavily on operator skill. | High, consistent Ra values, minimizes human error. |

| Adjustment Mechanism | Manual handwheel or lever adjustments, time-consuming. | Electric button/touch screen for rapid, precise adjustments. |

| Material Versatility | Limited, requires significant setup changes for different materials. | High, programmable settings for diverse materials and finishes. |

| Productivity | Lower throughput due to manual operations and setup times. | Higher throughput, continuous operation, reduced cycle times. |

| Energy Efficiency | Generally lower efficiency, older motor technology. | Optimized motors (e.g., IE3/IE4), VFDs for energy savings. |

| Safety Features | Basic safety mechanisms, potentially higher operator risk. | Comprehensive interlocks, emergency stops, enclosed design for enhanced safety. |

Customized Solutions and OEM Capabilities

The demand for specialized applications often necessitates tailored solutions, and this is where an oem round tube polishing machine provider truly excels. OEM capabilities allow for the development of bespoke machinery that precisely meets the unique challenges and operational requirements of a client's production environment.

Customization options can include:

- Specific Tube Dimensions: Adapting machines to handle exceptionally large or small diameter tubes, or non-standard lengths that a generic model cannot accommodate.

- Material-Specific Configurations: Designing polishing heads, abrasive types, and cooling systems optimized for exotic alloys, delicate materials, or plastics, ensuring the ideal finish without compromising material integrity.

- Integrated Automation: Developing systems that seamlessly integrate with existing robotic loading/unloading systems, automatic inspection equipment, or downstream processing lines, enhancing overall manufacturing flow.

- Advanced Control Systems: Implementing custom PLC programming, HMI interfaces with specific recipe management, remote diagnostics, and data logging capabilities to meet Industry 4.0 requirements.

- Environmental Controls: Incorporating specialized dust extraction, fume filtration, and coolant recycling systems designed for particular materials or operational safety standards.

- Specialized Finish Requirements: Engineering multi-stage polishing sequences to achieve highly specific surface roughness values (Ra), gloss levels, or deburring requirements for critical components.

Engaging with an experienced OEM means collaborating with a partner capable of translating complex requirements into robust, efficient, and cost-effective polishing solutions. This ensures that the investment in a round tube polishing machine is perfectly aligned with long-term strategic goals.

Real-World Application Case Studies

Case Study 1: High-Volume Stainless Steel Tube Polishing for the Food & Beverage Industry

Client Profile: A leading international manufacturer of food processing equipment, requiring high-volume production of stainless steel tubes (AISI 304 and 316L) for hygienic applications.

Challenge: The client needed to achieve an internal and external surface roughness of Ra

Solution: Implementation of a multi-head, fully automated round tube polishing machine system. This customized system featured eight polishing stations, each equipped with electric button controlled pressure adjustment and a sequential abrasive belt progression from coarse to ultra-fine grits. An integrated cleaning and drying unit ensured tubes were ready for immediate assembly.

Results: The client experienced a 35% increase in throughput, a 50% reduction in surface defect rejects, and a significant decrease in labor costs. The consistent Ra 0.18 µm finish not only met but exceeded industry standards, enhancing their product reputation and market share. "The consistency and speed of this machine are game-changers for our production line," reported the Head of Production.

Automated systems deliver superior and consistent results.

Case Study 2: Precision Titanium Tube Finishing for Aerospace Components

Client Profile: A specialized aerospace component manufacturer, producing thin-walled titanium alloy tubes for critical hydraulic and structural applications.

Challenge: Polishing thin-walled titanium tubes (Ø20-50mm, 0.8mm wall thickness) required extremely delicate handling to prevent deformation and ensure uniform material removal. The final surface finish needed to enhance fatigue life and comply with strict aerospace material specifications, with zero tolerance for micro-cracks or stress risers.

Solution: A custom-engineered round tube polishing machine was developed, featuring precise, electronically controlled polishing head pressure (with feedback sensors) and a specialized non-contact support system for the tubes. The system utilized specific ceramic-coated abrasive belts for titanium and a multi-stage process to gradually achieve the required finish without heat buildup or material degradation. An integrated eddy current inspection system was also incorporated for real-time quality assurance.

Results: The custom machine successfully achieved the stringent surface finish requirements (Ra

Ensuring Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: What tube materials can the Electric button to adjust the round steel tube polishing machine process?

- A: Our machines are highly versatile and can effectively polish a wide range of materials, including various grades of stainless steel (e.g., 304, 316L), carbon steel, aluminum, copper, brass, titanium, and select specialty alloys. Specific abrasive configurations can be optimized for each material.

- Q: How easy is it to change polishing wheels or belts?

- A: Our machines are designed for quick-change mechanisms. Polishing wheels and belts can typically be replaced within minutes, minimizing downtime and maximizing operational efficiency. User-friendly interfaces guide operators through the process.

- Q: What surface finishes (Ra values) can be achieved?

- A: Depending on the material, the number of polishing stages, and the abrasive sequence used, our machines can achieve a wide range of surface finishes, from a functional Ra 0.8 µm to a mirror-like Ra 0.05 µm.

- Q: What kind of maintenance is required for the polishing machine?

- A: Routine maintenance includes daily checks of coolant levels, abrasive condition, and general cleanliness. Weekly or monthly tasks involve lubricating moving parts, inspecting belts and rollers for wear, and cleaning the dust collection system. A detailed maintenance schedule is provided with each machine.

- Q: Is operator training provided?

- A: Yes, comprehensive operator and maintenance training is typically included as part of our service package. This can be conducted on-site during installation or at our facility, ensuring your team is fully proficient in operating and maintaining the round tube polishing machine.

Lead Time & Fulfillment Details

Standard models of the Electric button to adjust the round steel tube polishing machine typically have a lead time of 8-12 weeks from order confirmation to shipment. For highly customized oem round tube polishing machine configurations or systems with extensive automation integration, lead times may extend to 14-20 weeks. We provide detailed project timelines and maintain transparent communication throughout the manufacturing and delivery process. Our logistics team coordinates global shipping, customs clearance, and, where applicable, on-site installation and commissioning.

Warranty Commitments

All our round tube polishing machine units come with a standard 12-month warranty covering parts and labor, effective from the date of installation or commissioning. Extended warranty options, providing up to 24 or 36 months of coverage, are available upon request to offer additional peace of mind. Our warranty ensures that any manufacturing defects or component failures within the covered period are addressed promptly and professionally.

Comprehensive Customer Support

We are committed to providing exceptional after-sales support to maximize your investment. Our dedicated technical support team is available via phone and email during business hours for immediate assistance. We offer remote diagnostic capabilities to troubleshoot issues efficiently. For more complex problems, our experienced service engineers are available for on-site visits globally. Furthermore, we maintain a comprehensive inventory of genuine spare parts to ensure rapid replacement and minimize any potential downtime.

Robust design and engineering for long-term reliability.

The Future of Tube Polishing: Innovation and Connectivity

The landscape of industrial manufacturing is continuously evolving, and the domain of tube polishing is no exception. The future promises even greater integration of smart technologies, further enhancing the capabilities and efficiency of the round tube polishing machine. Expect to see advanced sensor arrays for real-time surface finish measurement and adaptive polishing, where machine parameters automatically adjust to achieve optimal results regardless of minor material inconsistencies.

Industry 4.0 connectivity will become standard, enabling seamless data exchange with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems. This will facilitate predictive maintenance, allowing machines to schedule their own service, order spare parts, and prevent costly breakdowns before they occur. The use of Artificial Intelligence (AI) and Machine Learning (ML) will optimize abrasive selection, polishing recipes, and energy consumption, pushing the boundaries of what the best round tube polishing machine can achieve. Furthermore, sustainability will remain a core driver, leading to innovations in eco-friendly abrasives and advanced closed-loop systems for water and dust management, further solidifying the role of sophisticated polishing solutions in modern, responsible manufacturing.

Continuous innovation drives the next generation of polishing technology.

References

- ASTM International. (n.d.). _ASTM Standards for Metals_. Retrieved from www.astm.org

- International Organization for Standardization. (n.d.). _ISO 9001: Quality Management Systems_. Retrieved from www.iso.org

- European Hygienic Engineering & Design Group. (n.d.). _EHEDG Guidelines for Hygienic Design_. Retrieved from www.ehedg.org

- Food and Drug Administration. (n.d.). _Regulations for Medical Devices and Food Processing_. Retrieved from www.fda.gov

- Manufacturing Execution Systems Association International. (n.d.). _MES Best Practices_. Retrieved from www.mesa.org