The Importance of GP Centerless Grinder Companies in Modern Manufacturing

In the fast-paced world of modern manufacturing, precision and efficiency are paramount. One of the critical tools that facilitate these objectives is the centerless grinder. Among the leading companies dedicated to this technology are GP centerless grinder companies, which have made significant contributions to the industry. This article delves into the role of GP centerless grinder companies, their impact on manufacturing processes, and the technological advancements they bring to the table.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece using a grinding wheel and a regulating wheel. Unlike traditional grinding methods, centerless grinding does not require the workpiece to be mounted on a fixture. Instead, it is held in place by the force applied from the regulating wheel, allowing for continuous production and higher throughput. This method is particularly advantageous for manufacturing cylindrical parts with high precision and uniformity.

The Role of GP Centerless Grinder Companies

GP centerless grinder companies specialize in the design, manufacturing, and service of centerless grinding machines. These companies have established a reputation for producing high-quality, reliable machines that meet the stringent demands of various industries, including automotive, aerospace, medical, and electronics. By focusing on innovation and precision engineering, GP companies help manufacturers streamline their production processes, reduce waste, and improve product quality.

One key advantage of partnering with a GP centerless grinder company is their ability to provide customized solutions. Many manufacturers operate in niche markets with specific requirements. GP companies understand this and often work closely with clients to develop tailored grinding solutions that fit the unique needs of their operations. This collaborative approach not only enhances efficiency but also fosters long-term partnerships between manufacturers and suppliers.

Technological Advancements

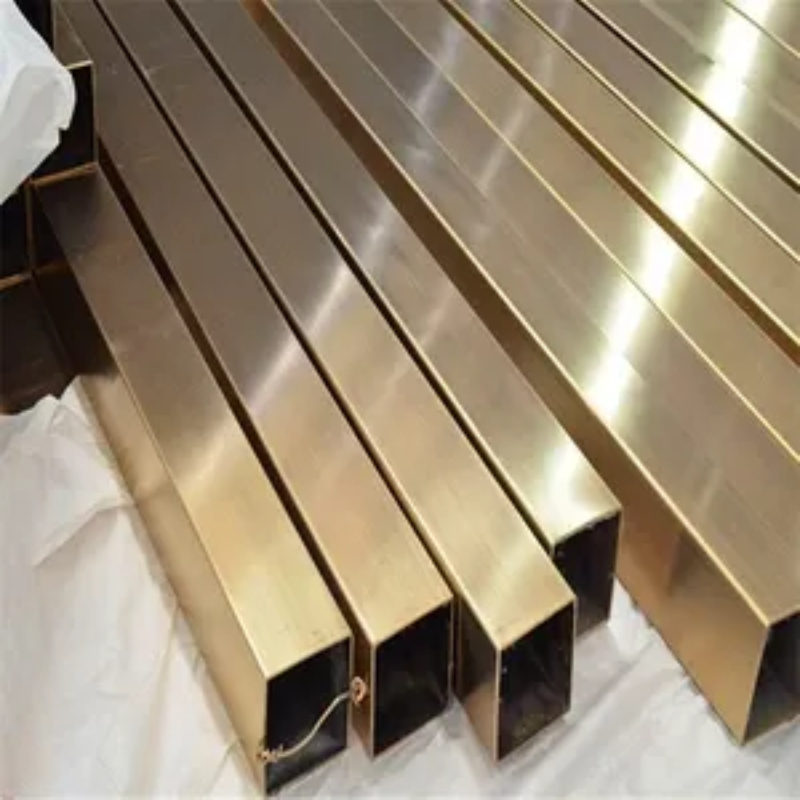

gp centerless grinder companies

As technology continues to evolve, GP centerless grinder companies are at the forefront of incorporating advanced features into their machinery. Modern centerless grinders now boast sophisticated control systems, automation capabilities, and improved grinding wheel designs. These advancements enable manufacturers to achieve tighter tolerances, enhance surface finishes, and increase overall productivity.

For instance, some GP companies have begun integrating computer numerical control (CNC) technology into their centerless grinding machines. CNC grinders allow for rapid adjustments and programming of various machining parameters. This flexibility results in reduced setup times and the ability to produce complex parts with minimal human intervention. Moreover, the integration of sensors and data analytics enables real-time monitoring of the grinding process, helping operators identify issues before they escalate and ensuring consistent quality.

The Future of GP Centerless Grinder Companies

Looking ahead, GP centerless grinder companies are likely to play a crucial role in the future of manufacturing. With the rise of Industry 4.0, the incorporation of IoT (Internet of Things) technology, and the push for sustainable manufacturing practices, these companies will need to adapt continuously. Emphasizing energy efficiency, minimizing material waste, and developing machines that support green manufacturing initiatives will become increasingly important.

Furthermore, as globalization continues to influence manufacturing dynamics, GP centerless grinder companies will face both challenges and opportunities. Competing in an increasingly interconnected marketplace means that these companies must remain agile, innovative, and responsive to customer needs. By focusing on research and development, GP companies can stay ahead of the technological curve and meet the evolving demands of their clients.

Conclusion

In conclusion, GP centerless grinder companies are essential contributors to the landscape of modern manufacturing. Their commitment to precision, innovation, and customer satisfaction not only drives efficiency and quality in production processes but also fosters strong partnerships across industries. As technological advancements reshape the manufacturing sector, these companies will undoubtedly continue to play a pivotal role in shaping the future of machining and grinding, ensuring that manufacturers can meet the demands of an ever-changing global market.