The Evolution and Importance of Flat Surface Polishing Machine Companies

In the realm of manufacturing and industrial processes, the finish of a product plays a pivotal role in determining its quality and usability. Among various finishing processes, polishing is a crucial step, especially for items that require a smooth, aesthetically pleasing surface. Flat surface polishing machines have emerged as essential tools in various industries, including metalworking, woodworking, and even in creating high-precision components for electronics and aerospace. This article delves into the significance of flat surface polishing machine companies and their influence on modern manufacturing.

The Functionality of Flat Surface Polishing Machines

Flat surface polishing machines are designed to achieve a high-quality finish on flat surfaces. These machines typically utilize abrasive materials to remove imperfections and enhance the surface integrity of various materials, such as metals, plastics, and ceramics. The machines can cater to large-scale production demands while ensuring consistency and precision in the polishing process.

Advanced features like programmable controls, automatic feeding systems, and varying speed settings enable manufacturers to customize the polishing process based on the material and desired finish. As industries demand higher productivity and efficiency, flat surface polishing machines continue to evolve, incorporating innovative technologies like automation, robotics, and real-time monitoring systems.

The Market Landscape

The market for flat surface polishing machines is continuously expanding, influenced by rapid industrialization and the increasing demand for high-quality finishes in products. Companies specializing in manufacturing these machines have diversified their offerings to cater to different sectors. Some of the prominent categories in the industry include

1. Small-scale Polishing Solutions Ideal for workshops and small businesses, these machines are designed for manual or semi-automated processes. They often feature compact designs and flexible configurations.

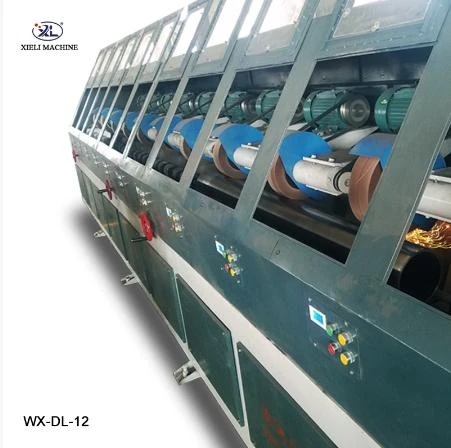

2. Industrial Polishing Systems These machines are robust and designed for heavy-duty use in factories and production plants. They usually have higher throughput and can handle larger components while maintaining precision.

3. High-Precision CNC Polishing Machines With the rise of advanced manufacturing techniques, CNC (Computer Numerical Control) polishing machines have gained popularity. They provide unparalleled precision and can be used for complex geometries, making them ideal for industries like aerospace and automotive.

flat surface polishing machine companies

Leading Companies in the Flat Surface Polishing Machine Sector

Several companies have established themselves as leaders in the flat surface polishing machine market. These companies innovate consistently, ensuring their products align with the latest technological advancements and industry demands.

- Buehler A prominent name in material preparation and analysis, Buehler offers a wide range of polishing machines renowned for their durability and efficiency. Their commitment to research and development ensures their products meet the evolving needs of industries.

- Lapmaster Wolters This company specializes in flat honing and polishing technology. They provide solutions tailored to various applications, including optics, metals, and ceramics. Their focus on precision makes them a favored choice for industries needing meticulous polishing.

- Parker Hannifin While primarily known for its engineering solutions, Parker Hannifin has ventured into the polishing machine arena, offering high-performance systems designed to optimize production processes and reduce operational costs.

Future Trends and Innovations

The future of flat surface polishing machine companies looks promising. As industries strive for sustainability, there is a growing emphasis on developing eco-friendly polishing solutions that minimize waste and energy consumption. Additionally, the integration of artificial intelligence (AI) and machine learning will likely transform the industry, enabling predictive maintenance, optimization of polishing parameters, and enhanced automation.

Furthermore, with the increasing adoption of Industry 4.0 practices, these companies must adapt to changing market dynamics. The ability to offer customized solutions, coupled with exceptional service and support, will determine their competitiveness in the global market.

Conclusion

Flat surface polishing machines are indispensable in today's manufacturing landscape, shaping the quality and performance of countless products. Companies involved in their production play a significant role in driving innovation, efficiency, and quality, catering to an ever-evolving market. As technology and industry standards continue to advance, flat surface polishing machine companies will undoubtedly remain at the forefront of enhancing surface finishes across diverse applications, contributing to the greater goal of achieving excellence in manufacturing and production.