The Rise of the Famous Tube Belt Polishing Machine

In the realm of manufacturing and metalworking, the pursuit of precision and surface perfection has led to the innovation of specialized machinery. One such notable invention is the tube belt polishing machine, celebrated for its efficiency and effectiveness in providing a flawless finish to metal tubes and pipes. This article delves into the importance, features, and applications of the famous tube belt polishing machine, highlighting why it has become an essential tool in various industries.

Understanding Tube Belt Polishing Machines

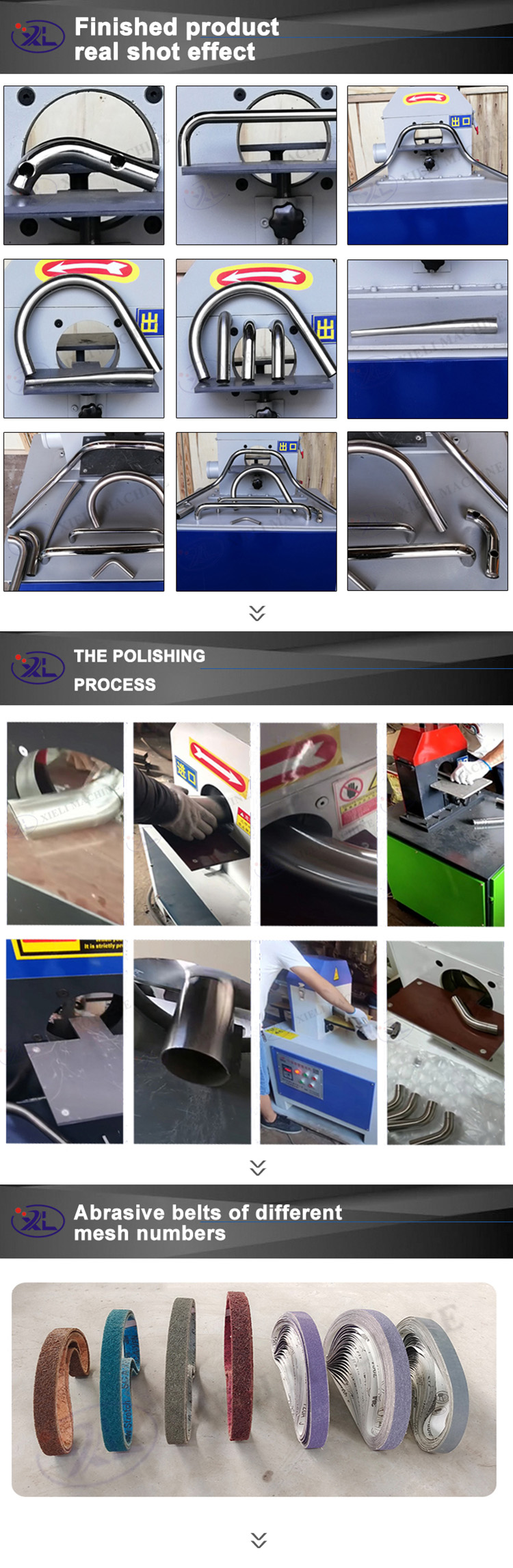

At its core, a tube belt polishing machine is designed to enhance the surface quality of metal tubes. It operates by utilizing a belt that is coated with abrasives, which moves over the surface of the tube at high speeds. The primary aim is to remove imperfections, oxidation, and other surface blemishes, resulting in a smooth and aesthetically pleasing finish. This machine is particularly adept at polishing stainless steel and other metals that are often used in the manufacturing of tubing for various applications.

Key Features

The famous tube belt polishing machine boasts several features that contribute to its popularity among manufacturers

1. Automation and Precision Modern polishing machines are often equipped with automated controls that ensure consistent pressure and speed, resulting in uniform polishing. This reduces the risk of human error and enhances the overall quality of the finished product.

2. Versatility These machines can accommodate various tube sizes and shapes, making them suitable for diverse industrial applications. Whether it's round, square, or rectangular tubes, a tube belt polishing machine can be tailored to meet specific needs.

3. Ease of Use User-friendly interfaces and simple operation procedures are key features of famous models. Operators can easily set parameters, monitor performance, and adjust settings as needed, allowing for efficient operation even in high-volume production environments.

4. Durability and Maintenance High-quality construction materials often used in these machines ensure longevity and resilience against wear and tear. Additionally, regular maintenance protocols are straightforward, making it easier for manufacturers to keep their machines running smoothly.

famous tube belt polishing machine

5. Enhancement of Productivity By automating the polishing process, manufacturers can significantly reduce labor costs and increase throughput. These machines allow for continuous operation, leading to higher production rates and improved efficiency.

Applications Across Industries

The tube belt polishing machine finds its application across a wide range of industries, underscoring its versatility and importance

1. Automotive Industry In automobile manufacturing, polished metal tubes are essential for both aesthetic and functional purposes. Components such as exhaust systems, frames, and other structures benefit from the enhanced surface quality offered by polishing machines.

2. Aerospace The aerospace industry demands precision and quality in all components, including metallic tubes. The tube belt polishing machine ensures that parts meet stringent safety and performance standards while maintaining a high-quality finish.

3. Construction Metal tubes used in construction applications, such as scaffolding and structural supports, require both strength and visual appeal. Polishing machines deliver the necessary finish to meet industry standards and client expectations.

4. Food and Beverage The food and beverage industry adheres to strict hygiene standards. Polished stainless-steel tubes are easier to clean and maintain, helping to prevent contamination. Tube belt polishing machines play a pivotal role in manufacturing equipment in this sector.

5. Chemical Processing In the chemical sector, tubes are often utilized for transporting fluids. A smooth surface can prevent corrosion and ensure the longevity of the equipment. Thus, polishing is crucial for both safety and effectiveness.

Conclusion

The famous tube belt polishing machine has revolutionized the way metal tubes are processed across various industries. With its combination of automation, precision, and versatility, it has proved indispensable for manufacturers seeking to enhance product quality while improving efficiency. As industries evolve and the demand for high-quality finishes continues to rise, the tube belt polishing machine is set to remain a pivotal tool in the metalworking arsenal. Investing in this machinery not only elevates production standards but also contributes to a company’s reputation for excellence in quality and craftsmanship.