The Importance of Stainless Steel Pipe Mirror Polishing Machines

In today’s industrial landscape, the demand for high-quality finishes on stainless steel products is at an all-time high. As industries ranging from construction to automotive and food processing expand, the need for precision in manufacturing processes has become critical. One of the essential pieces of equipment that have emerged in this context is the stainless steel pipe mirror polishing machine. This innovative machine not only enhances the aesthetic appeal of stainless steel pipes but also improves their functional qualities.

Understanding the Stainless Steel Pipe Mirror Polishing Machine

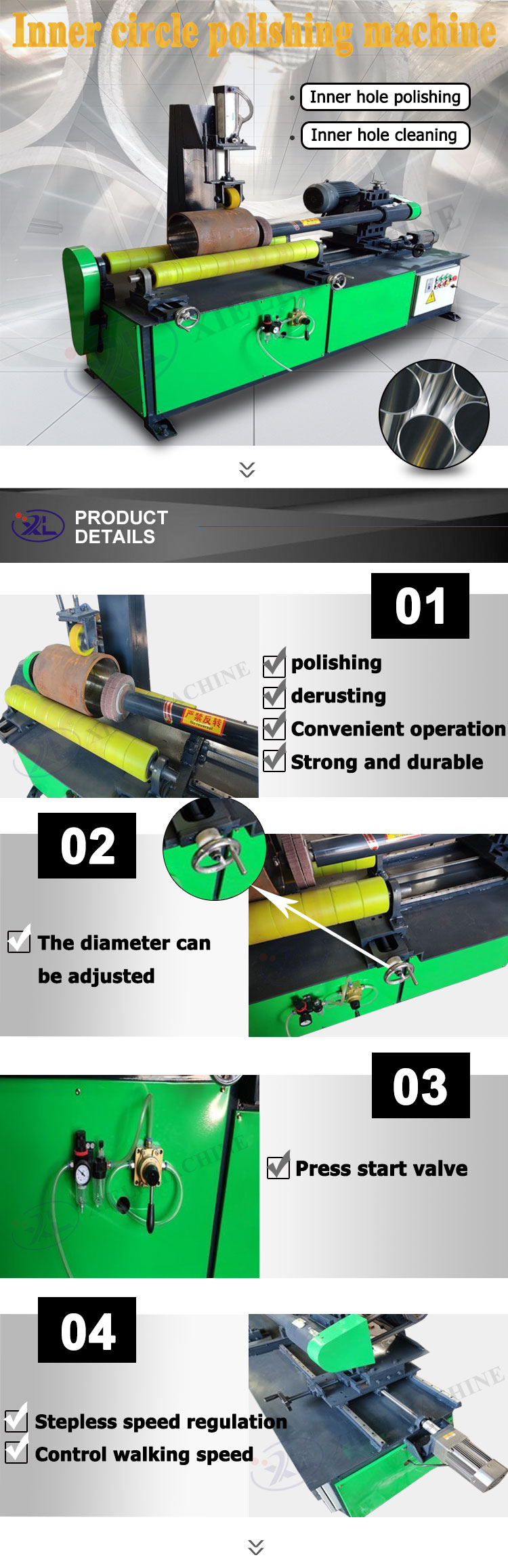

A stainless steel pipe mirror polishing machine is designed to achieve a high-gloss finish on stainless steel pipes. This machine utilizes a combination of mechanical polishing techniques and advanced abrasive materials to remove impurities, scratches, and oxidized layers from the surface of the pipes. The result is a shiny, mirror-like finish that is not only visually appealing but also corrosion-resistant and easy to clean.

These machines come equipped with various features, including adjustable speed settings, oscillating polishing arms, and advanced control systems that allow operators to customize the polishing process according to specific requirements. Such flexibility makes them suitable for a wide range of applications, from decorative items to functional components in high-stakes industries.

Benefits of Mirror Polishing

1. Aesthetics One of the most obvious benefits of mirror polishing is the visual enhancement it provides. Stainless steel pipes that are polished to a mirror finish can significantly improve the overall look of a product, making it more appealing to customers, particularly in industries where presentation matters.

2. Corrosion Resistance A smooth, polished surface is less susceptible to corrosion and staining. This is especially critical in industries such as food processing and pharmaceuticals, where hygiene and durability are paramount. Mirror-polished stainless steel pipes can withstand harsh environments and maintain their integrity over time.

famous stainless steel pipe mirror polishing machine

3. Ease of Maintenance Mirror-finished surfaces are easier to clean and maintain. The smooth finish reduces the adherence of dirt, oils, and other contaminants, making routine cleaning much simpler and more effective.

4. Enhanced Performance A polished surface can lead to improved flow characteristics in piping applications, reducing turbulence and enhancing the efficiency of fluid transfer.

The Role in Various Industries

Different sectors find immense value in using stainless steel pipe mirror polishing machines. In the architectural industry, for example, polished stainless steel is prevalent in the construction of modern buildings, railings, and other structural elements. The automotive industry also benefits from these machines, as they are used for exhaust systems and other components where both form and function are vital.

Furthermore, in the food and beverage sector, mirror-finished stainless steel pipes are used extensively in processing and storage applications. The polished surface ensures that the products meet stringent hygiene standards, thereby enhancing food safety.

Conclusion

In conclusion, the stainless steel pipe mirror polishing machine is an indispensable tool in contemporary manufacturing. Its ability to produce high-quality, aesthetically pleasing, and durable finishes makes it essential for various industries. As businesses continue to strive for excellence in their products and processes, investing in such advanced machinery will undoubtedly yield significant returns in terms of product quality, customer satisfaction, and long-term sustainability. Emphasizing the importance of this machinery not only reflects the technological advancement in manufacturing but also highlights the ongoing commitment to quality in modern production methods.