Understanding Discount Pipe and Tube Polishing Machines A Comprehensive Overview

In the realm of metalworking and fabrication, the importance of surface finish cannot be overstated. A polished surface is not only aesthetically pleasing but also crucial for preventing corrosion, enhancing durability, and ensuring the functionality of various components used in industries such as automotive, aerospace, and construction. Among the myriad of tools available to achieve a flawless finish, discount pipe and tube polishing machines have emerged as a cost-effective solution for many fabricators and manufacturers.

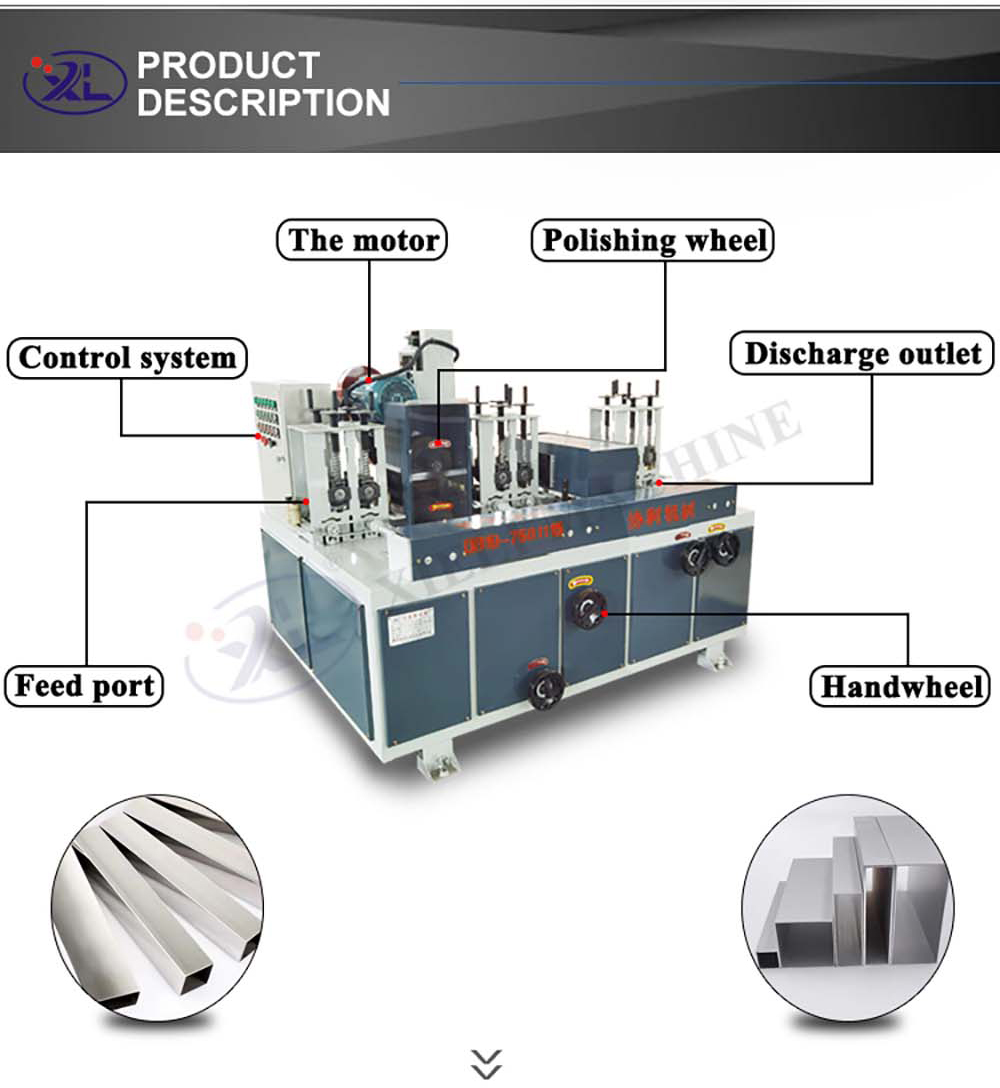

What Are Discount Pipe and Tube Polishing Machines?

Discount pipe and tube polishing machines are specialized equipment designed to smooth and polish the surfaces of tubular materials, including pipes and tubes made of metals like stainless steel, aluminum, brass, and more. These machines utilize various methods such as abrasive polishing, buffing, and chemical treatments to achieve the desired surface quality.

Key Features

1. Affordability As the name suggests, discount polishing machines are available at a lower price point compared to their high-end counterparts. This makes them attractive options for small businesses or startups looking to enhance their production capabilities without breaking the bank.

2. Versatility These machines can handle a range of tube sizes and shapes, making them suitable for applications across different industries. Whether you’re polishing a small diameter tube or a large pipe, a discount polishing machine can accommodate your needs.

3. User-Friendly Operation Many discount polishing machines come with simplified controls and automation features, allowing users with varying levels of expertise to operate them efficiently. This ease of use can significantly reduce training time and increase productivity.

discount pipe and tube polishing machine

4. Quality Finishing While they are budget-friendly, discount machines still deliver impressive polishing results. With the right tooling and technique, users can achieve mirror-like finishes that meet industry standards.

The Benefits of Utilizing These Machines

1. Cost Savings Investing in a discount pipe and tube polishing machine allows businesses to save money while still obtaining high-quality finishes. Lower initial costs commonly lead to a quicker return on investment.

2. Increased Productivity With effective polishing machines, manufacturers can speed up their production processes. Faster finishing times mean that projects can be completed more quickly, allowing businesses to take on more work.

3. Enhanced Product Quality A polished surface significantly improves the overall quality of the final product. By removing imperfections such as scratches and oxidation, companies can ensure that their pipes and tubes meet customer expectations.

4. Reduced Labor Costs Automation and user-friendly designs reduce the need for extensive manual labor. This can lower labor costs and minimize the risk of worker-related injuries due to less hands-on polishing work.

Conclusion

Discount pipe and tube polishing machines are invaluable tools for businesses aiming to improve their metal finishing capabilities without incurring exorbitant expenses. With a focus on efficiency, quality, and user-friendliness, these machines offer a viable solution in an increasingly competitive market. By investing in the right polishing equipment, fabricators can achieve outstanding results and maintain their competitive edge.