The Importance of Custom Centerless Grinder Blades in Precision Manufacturing

In the world of precision manufacturing, the significance of high-quality tooling cannot be overstated. Centerless grinding, a method used to grind cylindrical parts without the need for support, has become an essential process in various industries such as automotive, aerospace, and medical devices. The role of custom centerless grinder blades manufacturers is crucial as they provide specialized solutions tailored to meet specific production requirements.

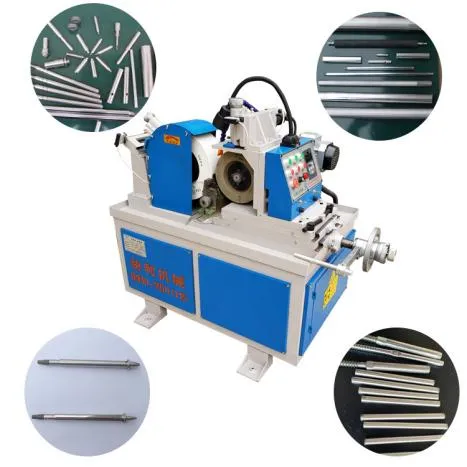

Centerless grinding works by placing a workpiece between two rotating blades a grinding wheel and a regulating wheel. This setup allows for the continuous feed of parts, leading to increased efficiency and throughput. However, to achieve optimal performance, the quality and precision of the grinding blades are paramount. Custom blade manufacturers focus on developing tailored solutions that cater specifically to the unique demands of different applications.

One of the primary advantages of custom centerless grinder blades is their ability to enhance efficiency. Off-the-shelf blades may not perfectly match the specifications needed for certain materials or part geometries. Custom blades are designed with the specific geometry, material, and coating requirements in mind, ensuring that they provide superior performance. This leads to reduced cycle times and lower production costs, as the right tool can significantly decrease the wear rates and improve the surface finish of the ground parts.

custom centerless grinder blades manufacturer

Additionally, custom blades are often developed using advanced technologies and high-grade materials, which enhance durability and effectiveness. Manufacturers can utilize various materials, such as carbide or ceramic, and can implement specific coatings that further minimize friction and wear. By selecting or developing the right combination of materials and designs, custom blade manufacturers play a vital role in extending the life of the grinding tools and improving overall productivity.

Moreover, collaborating with a custom centerless grinder blades manufacturer allows businesses to engage in a more strategic and cohesive production process. Engineers and designers can work closely with manufacturers to refine designs, create prototypes, and conduct trials to ensure the blades meet all performance criteria. This level of customization fosters innovation and allows manufacturers to stay competitive in an ever-evolving market.

The ability to adapt to changes in production needs is another compelling reason to consider custom solutions. As industries adapt and evolve, the requirements for grinding operations may shift as well. Custom blade manufacturers are equipped to quickly respond to these changes, ensuring that production workflows remain uninterrupted. This agility often results in a substantial competitive edge for companies committed to maintaining high standards in their operations.

In conclusion, custom centerless grinder blades play an indispensable role in the realm of precision manufacturing. From improving efficiency and durability to fostering collaboration and innovation, the contributions of specialized blade manufacturers are critical in meeting the unique challenges faced by industries today. For companies dedicated to precision and excellence, investing in custom solutions is not just an option; it is a necessity that can lead to greater productivity and success. As the manufacturing landscape continues to change, the need for tailored tooling solutions will only grow, positioning custom blade manufacturers as essential partners in the pursuit of high-quality production.