Centerless Grinder Suppliers and Manufacturers An Overview

In the realm of precision manufacturing, centerless grinding plays a pivotal role. Unlike conventional grinding methods, centerless grinding allows for the efficient processing of cylindrical parts without the need for a supporting fixture. This unique approach offers several advantages, including improved throughput, better surface finish, and lower operational costs. As a result, many industries, from automotive to aerospace, rely on centerless grinder suppliers and manufacturers to meet their machining needs.

When searching for centerless grinder suppliers, it is essential to consider several key factors that can influence the quality and efficiency of machining processes. First, the manufacturer's reputation in the industry is paramount. Established companies with a track record of delivering high-quality machines often have the expertise and experience necessary to provide reliable solutions.

Moreover, the technology employed in the manufacturing of centerless grinders significantly impacts performance. Advanced features such as CNC (Computer Numerical Control) systems, automatic feeding mechanisms, and high-precision grinding wheels can enhance the grinding process, allowing for tighter tolerances and greater output. It is advisable to seek suppliers who utilize the latest technology and innovation in their grinder designs.

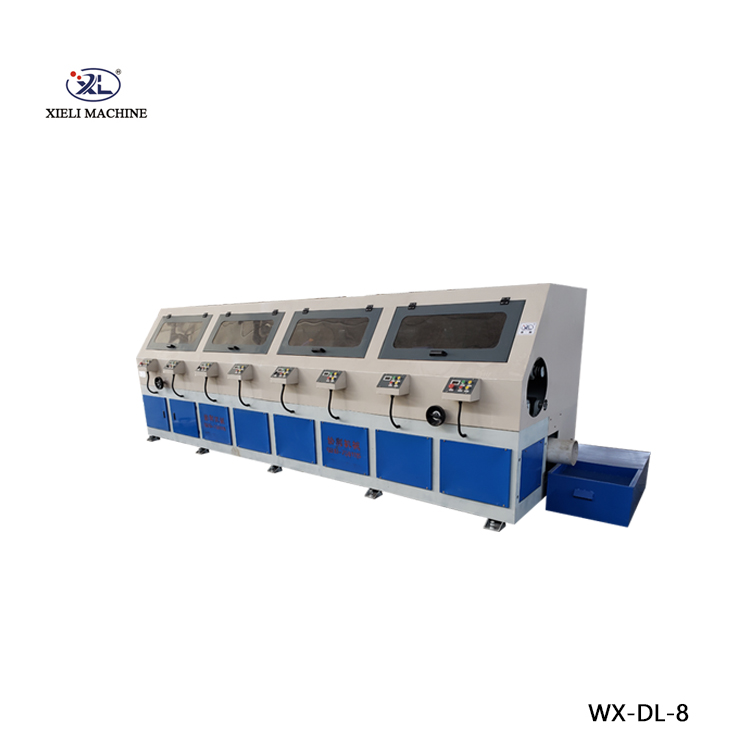

cnc centerless grinder suppliers manufacturer

Additionally, customer support and service after the sale cannot be overlooked. A reliable centerless grinder supplier should offer comprehensive support, including installation, training, and maintenance services. This ensures that manufacturers can maximize the performance and longevity of their machines, minimizing downtime and enhancing productivity.

When evaluating potential suppliers, it is also beneficial to look at the range of models and customization options available. Different applications may require specific grinder configurations, and suppliers who can provide tailored solutions will likely be more valuable partners. Whether for producing small batches or large-scale outputs, having access to a versatile lineup of centerless grinders can significantly contribute to operational efficiency.

Lastly, consider the supplier's commitment to quality assurance. Ensuring that the machinery meets international quality standards will not only guarantee optimal performance but also prolong the service life of the equipment.

In conclusion, selecting the right centerless grinder supplier and manufacturer is crucial for any business focused on precision machining. By considering factors such as industry reputation, technological advancement, customer support, customization options, and quality assurance, manufacturers can make informed decisions that enhance their production capabilities and drive success in the competitive marketplace.