The China Van Norman Centerless Grinder Precision and Efficiency in Manufacturing

In the ever-evolving landscape of manufacturing technology, precision and efficiency are paramount. Among the various tools that facilitate these essential qualities, the Van Norman centerless grinder stands out. This machine is designed to shape and finish parts with remarkable accuracy, and its application within the Chinese manufacturing sector cannot be overstated.

Understanding Centerless Grinding

Centerless grinding is a machining process that allows for the efficient grinding of cylindrical components without the need for traditional center mounts. Instead of relying on fixed centers to hold the workpiece, the process uses a support mechanism that keeps the part stable during grinding. This innovative approach not only accelerates production times but also minimizes the chance of errors, an essential factor as manufacturing demands escalate.

The fundamental components of a centerless grinder—including the grinding wheel, regulating wheel, and work rest—collaborate seamlessly. The grinding wheel removes material from the workpiece, while the regulating wheel controls the rotation and linear motion. The work rest provides support, ensuring that the part remains in the correct position throughout the grinding process.

The Rise of the China Van Norman Centerless Grinder

As China continues to emerge as a global manufacturing powerhouse, the adoption of advanced machinery like the Van Norman centerless grinder has gained traction. This grinder is not only effective in delivering precise results but also enhances productivity by allowing high-volume production runs without sacrificing quality.

The China Van Norman centerless grinder has become synonymous with reliability and durability. Engineering innovations have been specifically tailored to suit the needs of the Chinese market, accommodating both small-scale workshops and large manufacturing plants. The versatility of this machine allows it to handle a wide range of materials, from metals to plastics, further broadening its application.

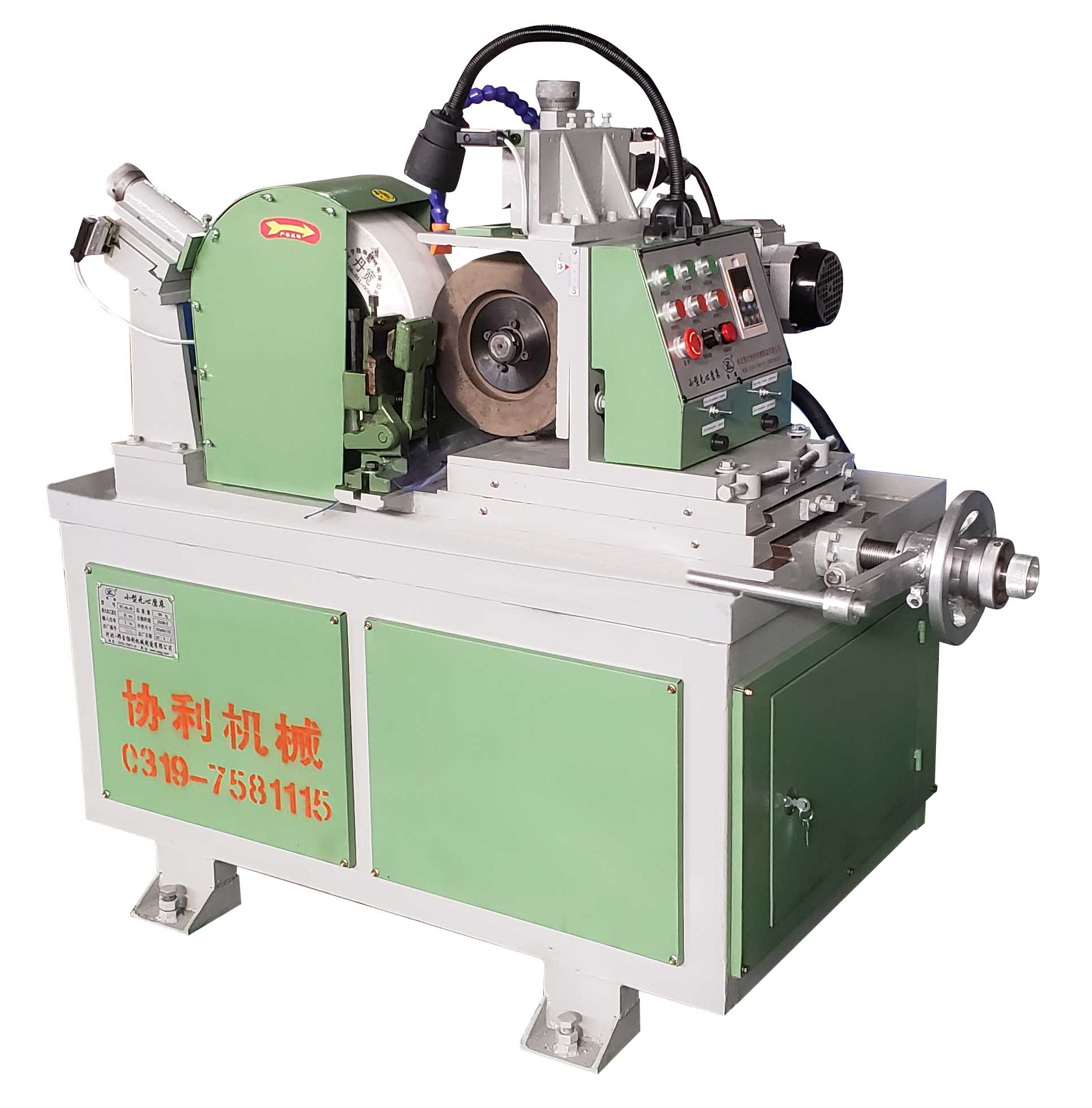

china van norman centerless grinder

Advantages in the Manufacturing Sector

One of the foremost advantages of using China’s Van Norman centerless grinder is the reduction in operational costs. Traditional grinding methods often require extensive handling and setup time, but the centerless approach minimizes these inefficiencies. Operators can achieve consistent results without the need for intricate setups, thus streamlining the workflow and enabling manufacturers to focus on meeting production targets.

Moreover, the accuracy provided by the centerless grinder significantly reduces the amount of rework necessary. In sectors such as automotive, aerospace, and electronics, where precision is crucial, this machine ensures that components meet stringent quality standards right from the start. The ability to produce parts with tight tolerances allows manufacturers to maintain a competitive edge in an increasingly demanding market.

Future Prospects

The future of the China Van Norman centerless grinder looks promising as industries continue to embrace automation and smart manufacturing practices. The integration of computer numerical control (CNC) technologies with centerless grinding machines is set to revolutionize the way parts are produced. Enhanced software capabilities will allow for real-time adjustments to grinding parameters, leading to even greater precision and efficiency.

As the Chinese manufacturing sector strives for global competitiveness, the role of centerless grinders will likely become even more pivotal. By maintaining a commitment to innovation and quality, manufacturers can leverage machines like the Van Norman grinder to meet the challenges of the modern landscape.

Conclusion

In summary, the China Van Norman centerless grinder represents a significant advancement in manufacturing technology. With its precision, efficiency, and adaptability, it is set to play an essential role in elevating the productivity and quality of manufacturing processes in China and beyond. As the industry evolves, embracing such innovations will be critical for driving future success and ensuring sustained competitiveness on a global scale.