Exploring Cheap Small Centerless Grinders Efficiency for Your Machining Needs

In the world of machining and metalworking, achieving precision and efficiency is paramount. One essential tool that has garnered attention in recent years is the centerless grinder. For small-scale operations and budget-conscious businesses, a cheap small centerless grinder can serve as an invaluable asset. This article delves into the advantages, functionality, and considerations when investing in these compact machines.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process used for shaping cylindrical workpieces without the use of intervals, such as centers or fixtures. This technique involves placing the workpiece between two grinding wheels, one of which is stationary while the other rotates. The process allows for continuous grinding of multiple parts with high precision and minimal human intervention, leading to reduced production times and increased yield.

Advantages of Small Centerless Grinders

1. Space Efficiency As manufacturing spaces often come at a premium, small centerless grinders occupy less floor space compared to their larger counterparts. This compact design makes them suitable for small workshops or production facilities.

2. Cost-Effectiveness The tag “cheap” does not imply a compromise in quality. Many affordable small centerless grinders are designed to deliver impressive results without breaking the bank. By selecting a cost-effective grinding machine, businesses can achieve efficiency while keeping their expenses in check.

3. Versatile Applications Small centerless grinders are not limited to high-volume production. These machines can effectively handle complex jobs, including the grinding of rods, tubes, and other cylindrical parts, making them versatile across different industries such as automotive, aerospace, and metal fabrication.

4. Reduced Setup Time Unlike traditional grinding machines that require precision setup and alignment, small centerless grinders simplify this process. Their inherent design allows for quick changeovers and adjustments, significantly reducing downtime between jobs.

5. Consistency and Quality The automation of the centerless grinding process ensures that each workpiece maintains a uniform quality, which is vital in industries where precision is critical. With less manual handling, there is a reduced scope for human error.

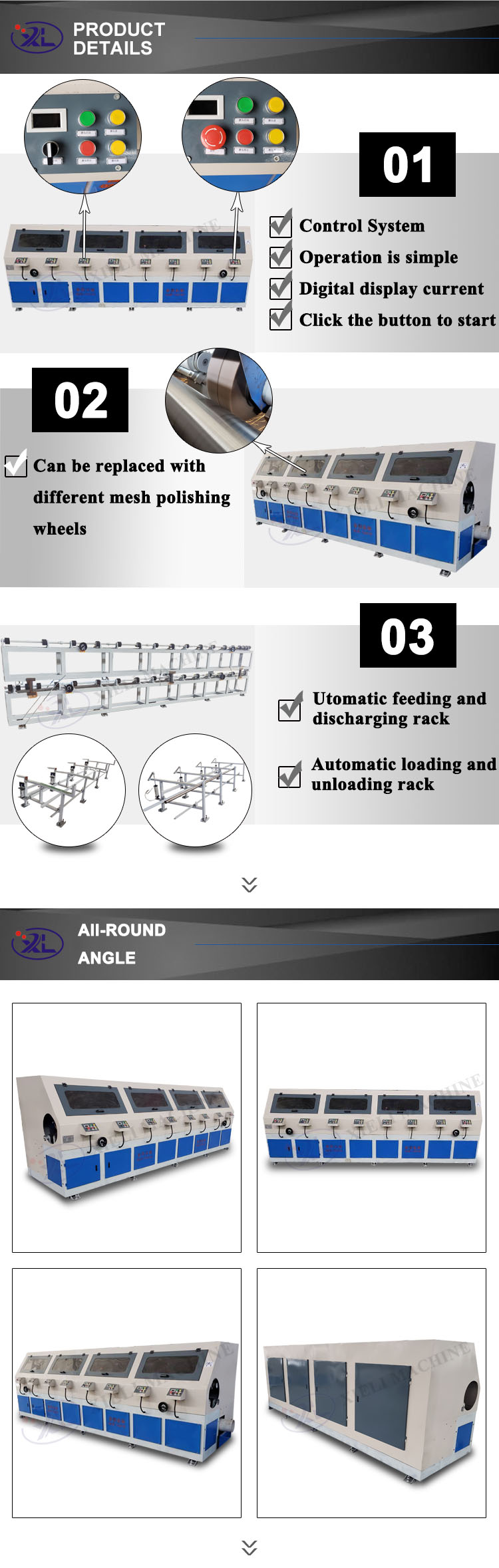

cheap small centerless grinder

Considerations When Purchasing

When looking for a cheap small centerless grinder, there are several factors to consider to ensure it meets your operational needs

- Specifications Evaluate the machine's speed, power, and capacity. Different models may be better suited for specific materials or sizes.

- Build Quality Even when shopping on a budget, the quality of construction is important. Look for models made from durable materials to ensure longevity and reliability.

- Safety Features As with any machinery, safety should always be a priority. Ensure that the grinder comes equipped with necessary safety features, such as emergency stops and guards.

- Support and Maintenance Research the manufacturer’s reputation for customer service and the availability of parts. A machine is only as good as the support behind it.

- User Reviews Checking customer reviews and feedback can provide insights into the reliability and performance of specific models, helping you make a more informed decision.

Conclusion

In conclusion, a cheap small centerless grinder can be an excellent addition to any small workshop or fabrication facility. With their efficiency, versatility, and space-saving design, these machines can enhance productivity and maintain high quality in finished products. When purchasing, it’s essential to consider specifications, safety features, and manufacturer support to ensure you select the right grinder for your specific needs. Embracing this technology can empower small businesses to compete effectively while keeping operational costs manageable.