Exploring the World of Centerless Valve Grinder Factories

The manufacturing industry relies heavily on precision and efficiency to produce high-quality products. Among the myriad of manufacturing processes, grinding plays a pivotal role in achieving the desired surface finish, dimensional accuracy, and overall performance of components. Particularly, centerless valve grinders have emerged as a critical machinery in the production of valve components used in various applications, from automotive to aerospace. This article explores the significance of centerless valve grinder factories, the technology involved, and the benefits they offer to manufacturers.

Understanding Centerless Grinding

Centerless grinding is a technique used to grind cylindrical workpieces without the need for centers or fixtures. Unlike traditional grinding methods that require the workpiece to be mounted and revolved on centers, centerless grinding supports the workpiece between two rotating wheels. The primary wheel, known as the grinding wheel, performs the grinding action while the regulating wheel controls the workpiece’s rotation and feed rate. This unique setup allows for exceptionally efficient and accurate grinding of valve components, which require tight tolerances and excellent surface finishes.

The Role of Valve Grinders in Manufacturing

Valves are essential components in numerous systems, controlling the flow of liquids and gases in engines, pipelines, and other machinery. The performance and reliability of these valves largely depend on the precision of the valve seats and other critical surfaces. Centerless valve grinders ensure that these surfaces are machined to the required specifications by removing material efficiently and uniformly.

Factories specializing in centerless valve grinding harness advanced technology to produce various types of valve components, including gate valves, ball valves, and check valves. The ability to produce high volumes of precision components quickly makes these factories a vital part of the supply chain in many industries.

Technological Advancements

As with many aspects of manufacturing, technology continues to evolve, and centerless valve grinder factories are at the forefront of these advancements. Modern centerless grinders are equipped with computer numerical control (CNC) systems, allowing for automated operation and precise control over every aspect of the grinding process. These systems can store multiple grinding parameters, enabling manufacturers to switch between different products seamlessly.

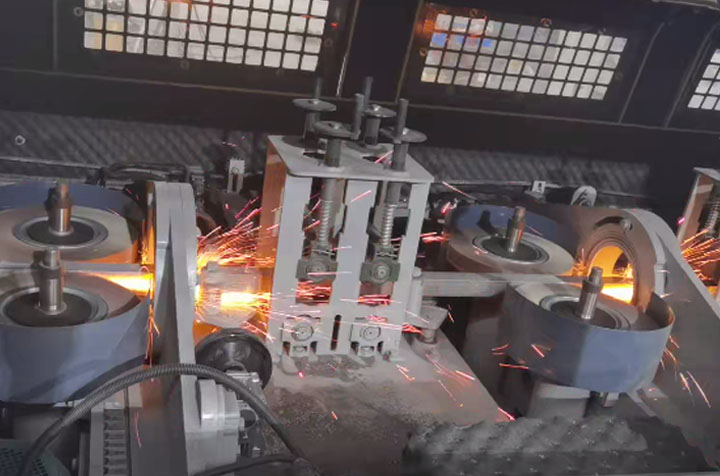

centerless valve grinder factories

Additionally, advancements in grinding wheel materials and designs enhance the grinding process. Superabrasive wheels made from cubic boron nitride (CBN) or diamond provide superior cutting efficiency and longer lifespan, enabling factories to achieve tighter tolerances while reducing operational costs. The implementation of real-time monitoring systems also ensures that any deviations from desired specifications are detected immediately, allowing for corrective actions without significant downtime.

The Benefits of Centerless Valve Grinder Factories

1. Increased Efficiency Centerless grinding processes significantly reduce cycle times compared to traditional grinding methods, enabling factories to meet high production demands without compromising quality.

2. Enhanced Precision The absence of centers minimizes potential errors associated with clamping and fixturing. Thus, components can be manufactured with remarkable precision, which is crucial for applications requiring tight tolerances.

3. Cost-Effectiveness By optimizing the grinding process and reducing material waste, centerless valve grinder factories can deliver high-quality products at competitive prices, making them attractive to manufacturers across various industries.

4. Flexibility With advanced CNC systems, manufacturers can quickly adapt to changes in production requirements. Whether it is a small batch of specialized components or a large order of standard valves, these factories can handle diverse production needs efficiently.

5. Superior Surface Finish The fine-tuning of grinding parameters allows for achieving excellent surface finishes, which are critical for proper sealing and functionality in valve applications.

Conclusion

Centerless valve grinder factories represent a fusion of technology and manufacturing expertise, making them indispensable in the production of precision valve components. With their ability to deliver high-quality products efficiently and cost-effectively, these factories are well-positioned to meet the growing demands of various industries. As technology continues to advance, the future of centerless grinding holds even more potential for enhancing manufacturing processes and contributing to the overall quality of industrial products. In an ever-evolving landscape, the role of centerless valve grinder factories will remain significant, driving innovation and efficiency in the manufacturing sector.