The Importance of Centerless Grinding Machine Parts Exporters

In the global manufacturing landscape, precision engineering plays a vital role, particularly in industries where the accuracy of components is critical. One of the key technologies that facilitate this precision is centerless grinding. This process is widely employed to produce components that require tight tolerances and superior surface finishes. The significance of centerless grinding machine parts exporters cannot be overstated, as they provide essential components that ensure the smooth functioning of these machines.

What is Centerless Grinding?

Centerless grinding is a manufacturing process that involves grinding cylindrical workpieces without the need for a center hole. Unlike traditional grinding methods, where the workpiece is held between centers, centerless grinding supports the workpiece on both ends through a series of rollers and a grinding wheel. This method is particularly advantageous for producing long, cylindrical parts in an efficient and economical manner. It is commonly used in industries such as automotive, aerospace, and medical manufacturing.

The Role of Machine Parts Exporters

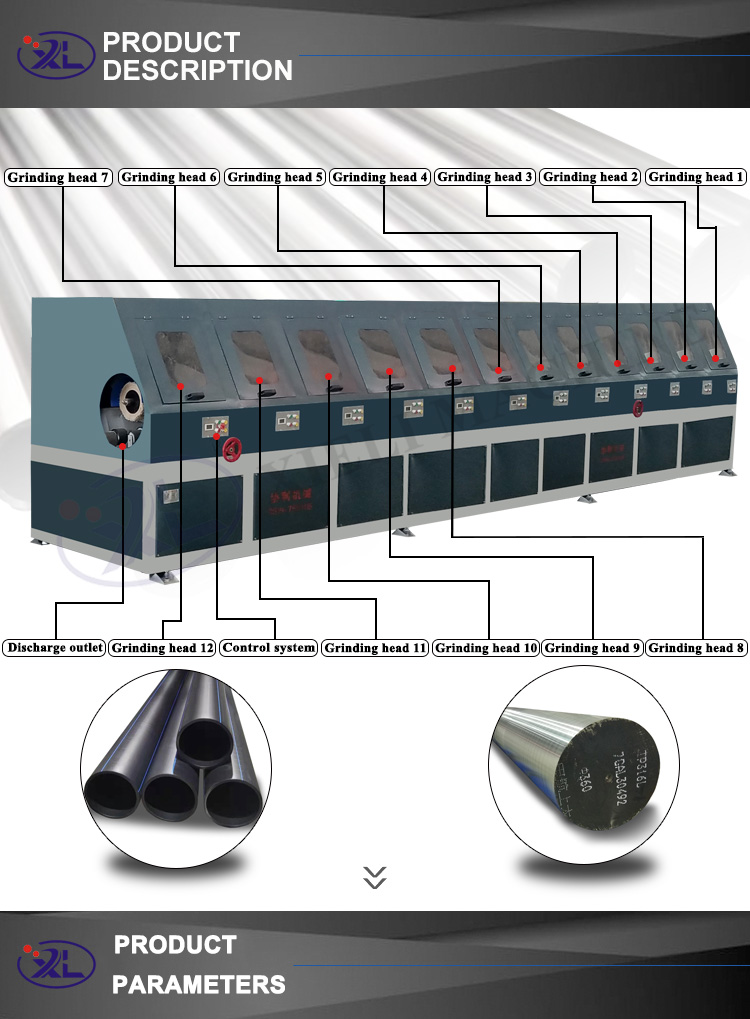

Exporters of centerless grinding machine parts play a crucial role in the manufacturing supply chain. They ensure that high-quality parts are available for manufacturers worldwide. These parts may include grinding wheels, adjusting nuts, work rests, and various other components essential for the operation of centerless grinding machines. By providing these parts, exporters help facilitate uninterrupted production processes, enabling manufacturers to meet their delivery deadlines and maintain product quality.

Quality Assurance in Exported Parts

One of the primary concerns for manufacturers when sourcing machine parts is quality. High-quality components are essential for the reliability and efficiency of centerless grinding machines. Exporters who specialize in these parts typically adhere to strict quality control measures to ensure their products meet international standards. This often involves rigorous testing and inspection processes to ensure that each part can withstand the demanding conditions of manufacturing environments.

centerless grinding machine parts exporters

Challenges in the Export Market

Despite the critical role played by centerless grinding machine parts exporters, the industry faces several challenges. One of the most significant challenges is the fluctuation in international trade regulations and tariffs. Exporters must navigate these changes while ensuring that they remain competitive in the global market. Additionally, the increasing demand for customized machine components adds another layer of complexity. Exporters must be agile and responsive to these evolving requirements to cater to diverse industry needs.

The Future of Centerless Grinding Parts Exporting

The future of centerless grinding machine parts exporting appears promising, with the increasing push for automation and smart manufacturing. As manufacturers invest in advanced technologies, the demand for precision-engineered components is expected to rise. Exporters who can leverage technology to optimize their supply chains and enhance product quality will be well-positioned to thrive in this dynamic market.

Moreover, the growing trend of sustainability in manufacturing will likely influence the exporting landscape. Exporters may need to embrace sustainable practices, such as reducing waste and improving energy efficiency in their operations. This shift not only meets the growing customer demand for greener products but also positions exporters as responsible players in the global economy.

Conclusion

In conclusion, centerless grinding machine parts exporters are integral to the manufacturing sector, ensuring that high-quality components are available for production processes. Their role extends beyond merely supplying parts; they are crucial in maintaining the operational efficiency and quality assurance standards necessary for modern manufacturing. As the industry continues to evolve, these exporters will need to adapt to new challenges and opportunities, paving the way for a robust and sustainable future in precision engineering. The continued collaboration between manufacturers and exporters will be essential in driving innovation and maintaining the competitive edge in global markets.