Centerless Grinding Machine Manufacturers and Exporters

In the modern manufacturing landscape, the precision and quality of machined components are critical to the success of various industries, including automotive, aerospace, and medical devices. One of the critical processes that contribute to this precision is grinding, particularly through centerless grinding machines. These machines are designed to grind workpieces without the need for a center support, making them an essential tool in high-volume production environments. The demand for effective and reliable centerless grinding machines has led to the emergence of numerous manufacturers and exporters in this niche market.

What is Centerless Grinding?

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. In contrast to traditional grinding methods, the workpiece is not held between centers. Instead, it is supported by a work rest blade and driven by a grinding wheel. This method offers numerous advantages, including the ability to work on multiple pieces simultaneously, uniform material removal, and enhanced productivity. The efficiency and effectiveness of centerless grinding make it a preferred choice for producing cylindrical parts with precise dimensions, such as shafts, pins, and dowels.

Global Market for Centerless Grinding Machines

The market for centerless grinding machines is expanding due to the increasing need for high-precision components in various industries. As manufacturers strive to improve their production processes and product quality, the demand for advanced grinding solutions continues to rise. Key manufacturers and exporters around the globe are focusing on technological advancements, offering machines that incorporate automation, digital controls, and enhanced safety features.

Countries such as India, Japan, Germany, and the United States are leading players in the centerless grinding machine manufacturing sector. Indian manufacturers, in particular, have gained recognition for their cost-effective yet high-quality machines. These manufacturers are not only catering to domestic markets but also exporting machines to developed countries, thus enhancing their global presence.

Key Features of Centerless Grinding Machines

When investing in centerless grinding machines, manufacturers typically look for specific features that enhance performance and productivity. Some of the standout features include

1. High Precision Modern centerless grinding machines offer exceptional precision, allowing for tight tolerances that are crucial in sectors like aerospace and medical manufacturing.

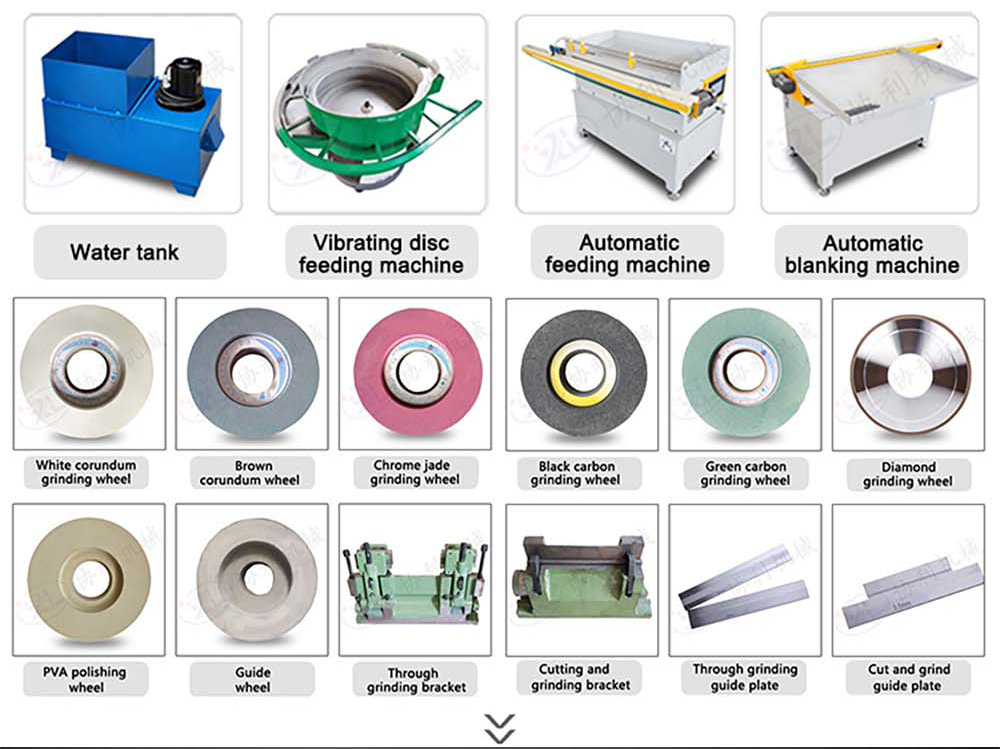

centerless grinding machine manufacturers exporter

3. Versatility With the option to grind various materials and sizes, manufacturers can operate more flexibly, adapting to changing production needs without significant downtime.

4. User-Friendly Controls Advanced digital controls help operators monitor the grinding process in real-time, allowing for quick adjustments and maintenance.

5. Durability High-quality construction materials used in these machines ensure longevity, reducing the need for frequent repairs and replacements.

Challenges Faced by Manufacturers

Despite the positive outlook, manufacturers of centerless grinding machines face several challenges. Rapid technological advancements necessitate continuous investment in research and development to keep pace with industry demands. Additionally, global competition can put pressure on pricing strategies, pushing manufacturers to optimize operations without compromising quality. Supply chain disruptions, especially in the wake of global events like pandemics, can also hinder production capabilities and timely deliveries.

The Future of Centerless Grinding

Looking forward, the future of centerless grinding machines appears bright, with several trends shaping the industry. Increased integration of AI and machine learning technologies is expected to enhance automation and predictive maintenance capabilities. Furthermore, the growing emphasis on sustainability and energy efficiency may lead to the development of more eco-friendly grinding solutions.

As industries evolve, the importance of precision engineering cannot be overstated. Centerless grinding machines will undoubtedly play a crucial role in meeting the demands of modern manufacturing. Manufacturers and exporters who adapt to these changing trends, focus on innovation, and maintain high-quality standards will likely emerge as leaders in the global marketplace.

Conclusion

Centerless grinding machine manufacturers and exporters are at the forefront of delivering precision solutions that meet the complex needs of various sectors. With technological advancements and a keen focus on quality, these manufacturers are not only enhancing production capabilities but also contributing to the overall efficiency of the global supply chain. As the landscape of manufacturing continues to evolve, the role of centerless grinding machines will remain vital, ensuring that industries can achieve the precision required in today's competitive environment.