Understanding Centerless Grinder Prices Factors Influencing Cost and Value

Centerless grinding is a precision machining process that plays a crucial role in various industries, particularly in manufacturing and engineering. This technique allows for the efficient grinding of cylindrical parts without the need for centers or fixtures, making it an essential operation in producing high-volume components. One critical aspect that businesses considering this machining method must address is the price of centerless grinders. In this article, we will explore the factors influencing the price of centerless grinders and how to determine their value.

What is a Centerless Grinder?

Before delving into pricing, it’s essential to understand what a centerless grinder is. A centerless grinder is a machine used to grind cylindrical workpieces, typically sized between 0.5 mm to 400 mm in diameter. The process is characterized by the absence of a spindle or a fixture that holds the workpiece in place. Instead, the workpiece is supported by the grinding wheel and a regulating wheel, allowing for increased efficiency and precision. Centerless grinding is commonly used for components such as rods, tubes, and various metal parts.

Factors Influencing Centerless Grinder Prices

1. Machine Type and Configuration Centerless grinders come in various configurations, including in-feed and through-feed types. The complexity of the machine design directly impacts its cost. In-feed grinders tend to be more expensive due to their ability to handle intricate parts. Through-feed grinders, on the other hand, are typically cheaper and are suitable for simpler, more uniform workpieces.

2. Brand and Manufacturer The reputation and reliability of the manufacturer significantly influence prices. Well-established brands that are known for producing high-quality machines often command higher prices because of their proven track records in performance, durability, and customer support. Lesser-known brands may offer lower prices but could compromise on quality and service.

3. Features and Technology Modern centerless grinders come equipped with advanced features such as numerical control (NC), CNC automation, and enhanced safety technologies. These features simplify operation, improve precision, and reduce the risk of human error, but they also drive up the price. Buyers must assess which features are essential for their specific applications versus those that may not justify the additional costs.

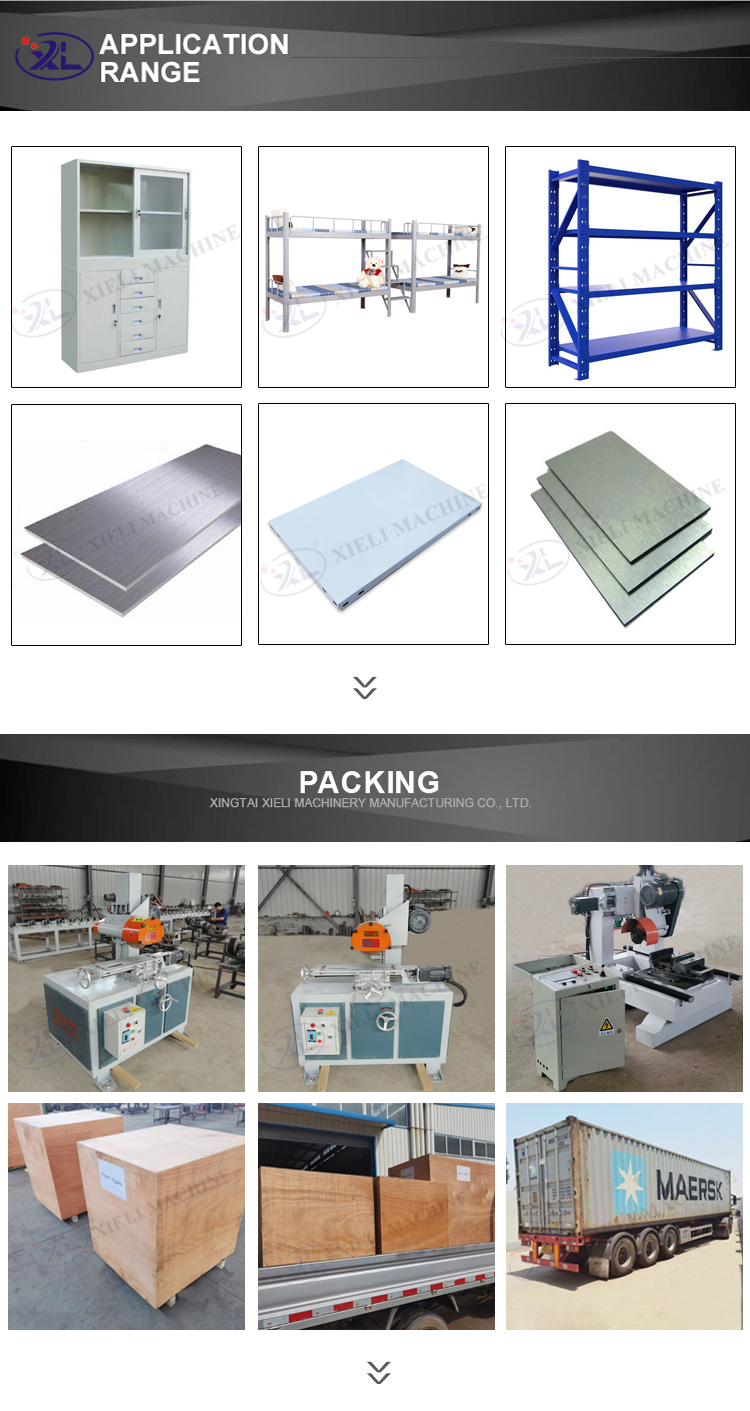

centerless grinder price product

4. Size and Capacity The size of the centerless grinder is another significant factor affecting its price. Larger models with the capability to handle bigger workpieces or higher production volumes will generally cost more. Businesses must consider their production needs and choose a machine that aligns with their operational requirements without overspending on unnecessary capacity.

5. Condition of the Machine Prices can vary considerably between new and used centerless grinders. New machines often come with warranties and the latest technology but are significantly more expensive. Used or refurbished machines can be a cost-effective solution, provided they are in good working condition and have been properly maintained.

6. Market Demand and Trends Like any product, the pricing of centerless grinders can be influenced by market demand and industry trends. A surge in demand for precision machined parts can lead to an increase in prices as manufacturers capitalize on the trend. Conversely, a downturn in economic activity might lead to competitive pricing and discounts.

Evaluating the Value of a Centerless Grinder

When considering the purchase of a centerless grinder, it is essential to look beyond the initial price. The total cost of ownership should include factors such as maintenance, spare parts availability, and energy consumption. Additionally, consider the machine’s efficiency and the quality of the output. A higher-priced, reliable machine that consistently produces quality components may prove to be more economical in the long run than cheaper alternatives that require frequent repairs or yield subpar results.

Conclusion

The price of centerless grinders can vary significantly based on multiple factors, including machine type, brand, features, and market dynamics. For businesses seeking to invest in this essential machining technology, understanding these pricing factors is crucial. By assessing their specific needs, evaluating the total cost of ownership, and considering long-term benefits, companies can make informed decisions that enhance their production capabilities while optimizing costs. Ultimately, investing in the right centerless grinder could provide companies with enhanced precision, efficiency, and profitability.