Centerless Grinder Parts Exporter A Comprehensive Overview

In the manufacturing and machining sector, precision is a non-negotiable attribute. One of the critical machines that facilitate precision grinding is the centerless grinder. This equipment is essential for producing high-quality cylindrical parts, where parts are fed through the grinding wheels without the need for centers to align the workpiece. As a result, centerless grinders have found widespread applications in industries such as automotive, aerospace, and medical devices. For businesses that rely on these machines, the role of a centerless grinder parts exporter becomes pivotal.

The Significance of Centerless Grinding

Centerless grinding is unique because it allows for the processing of workpieces without the requirement of a fixed point of reference. This process is particularly advantageous for mass production, as it enables continuous feeding of materials through the grinder, maximizing efficiency and throughput. The absence of centers also means that smaller parts can be ground with great precision, making this method ideal for producing components like shafts, pins, and bushings.

However, like any intricate machinery, centerless grinders require various parts and components to function optimally. From grinding wheels and workrests to in-feed and regulating wheels, every component plays a vital role in maintaining the machine's precision and durability. This is where centerless grinder parts exporters come into the picture.

Role of Centerless Grinder Parts Exporters

Centerless grinder parts exporters play a crucial role in providing manufacturers with the necessary components to keep their machines running smoothly. These exporters source and supply high-quality parts from reputable manufacturers, ensuring that clients receive durable components that meet industry standards. By acting as intermediaries, they help reduce lead times and logistics challenges associated with sourcing parts from multiple suppliers.

Exporters are well-versed in the specific requirements of various types of centerless grinders, whether they are traditional models or the latest CNC-controlled machines. This expertise allows them to recommend the most suitable parts based on the specific grinding application and operational needs of their clients.

Key Components Offered by Exporters

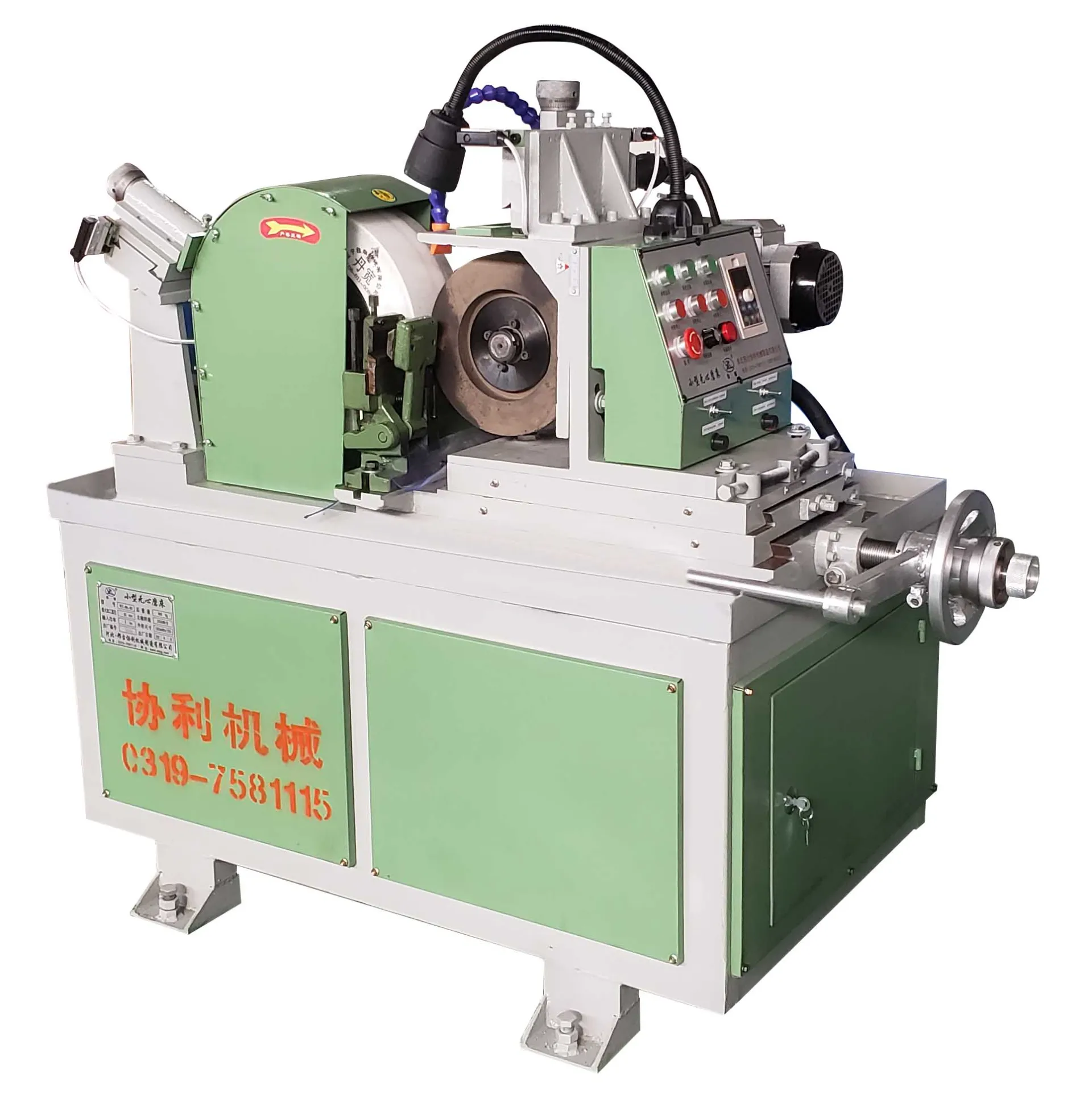

centerless grinder parts exporter

1. Grinding Wheels The heart of the grinding process, grinding wheels come in various sizes and compositions, tailored to different materials and operations. High-quality grinding wheels ensure efficient material removal while maintaining the required surface finish.

2. Regulating Wheels These wheels control the feed rate of the workpiece into the grinding zone. A properly matched regulating wheel is essential for maintaining the dimensional tolerances of the finished parts.

3. Workrests and V-Blocks These components provide stability and support for the workpiece during the grinding process. An accurate workrest is crucial for achieving precision in cylindrical grinding.

4. Spindles and Bearings Essential for the smooth operation of grinding wheels, health spindles and bearings reduce friction and wear, prolonging the lifespan of the grinder.

5. Hydraulic and Pneumatic Systems Many centerless grinders utilize hydraulic or pneumatic systems for operation. Exporters provide high-quality components, such as pumps and valves, to ensure reliable performance.

Quality Assurance and Standards

One of the key benefits of working with a reputable centerless grinder parts exporter is their commitment to quality. Exporters often adhere to international standards, such as ISO 9001, which ensures that the parts supplied meet stringent quality control measures. This focus on quality helps manufacturers minimize downtime due to component failure and enhances the overall efficiency of production processes.

Conclusion

In conclusion, the role of centerless grinder parts exporters is indispensable for industries that rely on precision grinding. By providing high-quality components, these exporters not only support manufacturers in maintaining their equipment but also play a critical part in ensuring the quality of the final products. The continued demand for precision-engineered parts guarantees that the centerless grinding process will remain a cornerstone of manufacturing efficiency for years to come. As industries evolve and innovate, the partnership between manufacturers and parts exporters will further strengthen, driving advancements in machining technology and productivity.