The Role of Centerless Grinder Blades in Precision Manufacturing

In the realm of precision manufacturing, centerless grinding plays a crucial role, particularly in the production of components that require tight tolerances and high surface finishes. Central to this process are the blades used in centerless grinders, which must meet stringent performance criteria to ensure efficiency and quality.

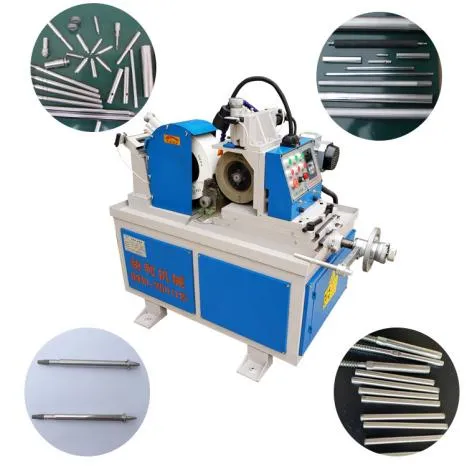

Centerless grinding is unique because it eliminates the need for a spindle or fixture to hold the workpiece. Instead, the component is held in place by a regulating wheel and a grinding wheel, allowing for a continuous and efficient grinding process. This method is particularly beneficial for shaping cylindrical parts such as shafts, rods, and tubes, which are common in the automotive, aerospace, and medical industries.

The importance of high-quality centerless grinder blades cannot be overstated. Manufacturers rely on these blades to maintain precision and consistency throughout the production process. The choice of material, blade design, and manufacturing techniques directly influence the performance of the grinding operation. Renowned manufacturers of centerless grinder blades focus on the following key aspects

1. Material Selection Premium blades are often made from high-speed steel (HSS) or carbide to withstand the rigors of grinding without quickly wearing out. The durability and hardness of the material allow these blades to maintain their sharpness for longer periods, reducing downtime and increasing productivity.

2. Blade Geometry The design and geometry of the blades play a significant role in their cutting efficiency. Manufacturers invest in advanced design technologies to create blades that optimize cutting angles and improve chip removal. A well-designed blade ensures smoother operation and enhances surface finish quality.

centerless grinder blades manufacturer companies

3. Precision Manufacturing To meet the tight tolerances required in precision engineering, blades must be manufactured using advanced techniques such as CNC machining and grinding. These processes guarantee dimensional accuracy and surface integrity, which are critical for the overall performance of the grinding operation.

4. Custom Solutions Every manufacturing operation has unique requirements, and leading manufacturers of centerless grinder blades often offer customized solutions. By collaborating with clients, manufacturers can produce blades tailored to specific applications, ensuring optimal performance and efficiency.

5. Innovation and Technology Continuous investment in research and development enables balde manufacturers to stay ahead of Industry 4.0 trends. Innovations such as coatings that reduce friction and enhance tool life are becoming increasingly popular. These advancements not only improve operational efficiency but also contribute to sustainable manufacturing practices by minimizing waste and energy consumption.

6. After-Sales Support Providing excellent customer support is essential for manufacturers of centerless grinder blades. Offering maintenance, repair services, and product training helps ensure that clients can maximize the lifespan and performance of their blades.

In conclusion, the role of centerless grinder blades in precision manufacturing is pivotal. As industries strive for greater efficiency and quality, the demand for high-performance blades will continue to grow. Companies investing in advanced materials, precision manufacturing, and customer-centric solutions will undoubtedly lead the charge in meeting the evolving needs of the market.