Centerless Grinders for Sale A Comprehensive Overview for Suppliers

Centerless grinding is a precision machining process that has gained immense popularity in various manufacturing sectors due to its efficiency and ability to produce high-quality finished products. As industries continue to evolve, the demand for centerless grinders has increased, leading many suppliers to explore opportunities in this niche market.

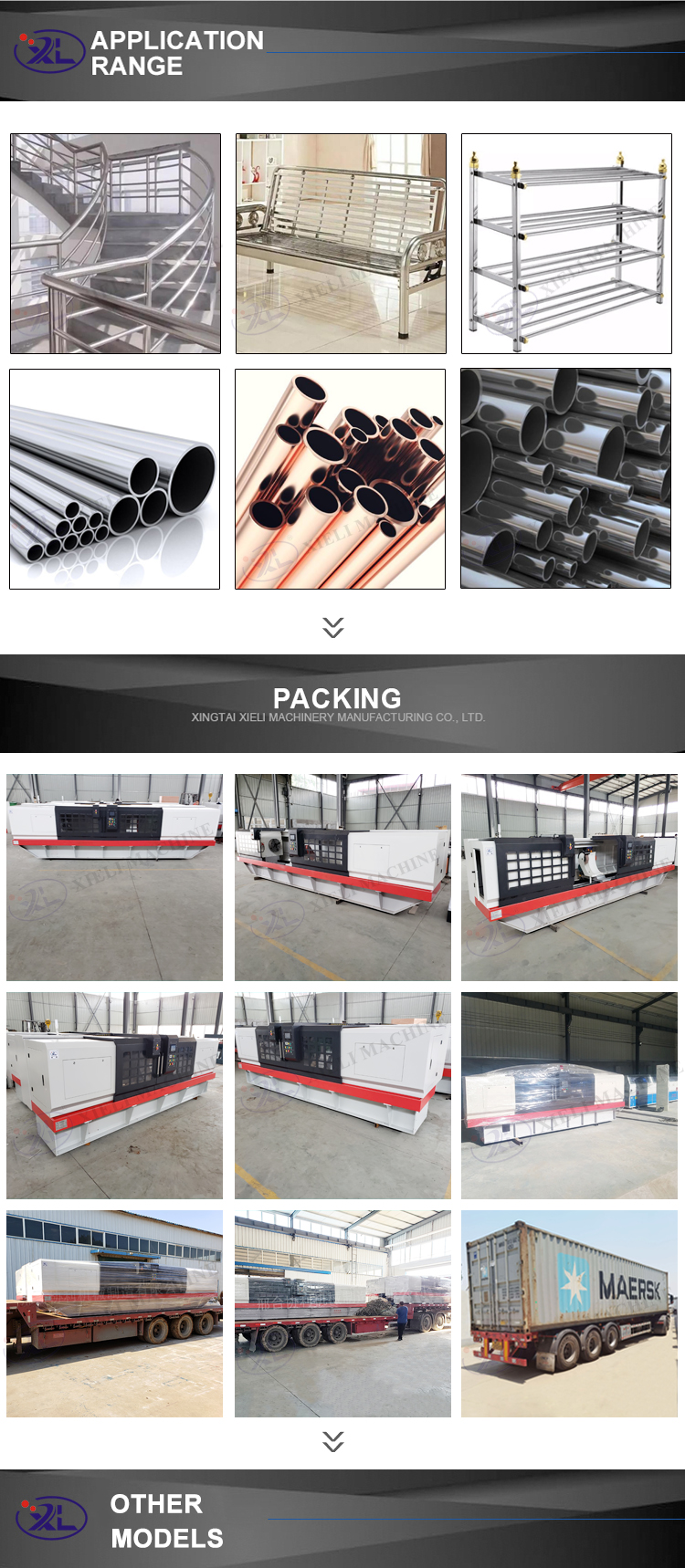

When searching for centerless grinders for sale, suppliers must consider the specific needs of their customers. There are two primary types of centerless grinding through-feed and in-feed. Through-feed grinding involves the workpiece being fed continuously through the grinding wheels, making it ideal for long and cylindrical parts. In-feed grinding, on the other hand, is suitable for shorter workpieces with complex shapes that require precise control. Suppliers should offer both types to cater to a diverse clientele.

Quality is paramount when sourcing centerless grinders. Reputable manufacturers use high-grade materials and advanced technology to ensure their machines operate with precision and reliability. Features such as rigid construction, advanced grinding controls, and the ability to handle various materials are critical aspects that potential buyers will consider. Suppliers should provide detailed specifications and performance metrics to help customers make informed decisions.

centerless grinder for sale suppliers

Additionally, after-sales service and support play a crucial role in supplier success. Providing installation guidance, maintenance services, and availability of spare parts can significantly enhance customer satisfaction. Establishing a strong relationship with clients often leads to repeat business and referrals, which are vital in a competitive market.

Moreover, suppliers should keep an eye on technological advancements in the centerless grinding industry. Innovations such as CNC (Computer Numerical Control) machining have transformed the traditional grinding processes, allowing for greater accuracy and automation. Offering state-of-the-art machines that embody these technological improvements can help suppliers differentiate themselves from competitors.

Lastly, industry trends indicate a growing emphasis on sustainability. Suppliers of centerless grinders can appeal to environmentally conscious manufacturers by providing energy-efficient models or those designed to minimize waste during the grinding process.

In conclusion, the market for centerless grinders presents a lucrative opportunity for suppliers. By focusing on quality products, excellent customer service, technological advancements, and sustainability, suppliers can position themselves favorably in this competitive landscape, ultimately driving business growth and success.