Centerless Belt Grinder A Comprehensive Overview

In the realm of industrial machining and surface finishing, the centerless belt grinder stands out as a powerful tool that enhances efficiency and precision. This innovative piece of equipment is particularly valued in manufacturing settings where the smoothness and uniformity of parts are crucial.

A centerless belt grinder operates on a simple yet effective principle it does not require a fixture to hold the workpiece. Instead, the workpiece is placed between two grinding wheels and is fed through the machine. This design allows for continuous grinding, as the workpiece is constantly guided by the wheels. The centerless approach not only improves speed but also significantly reduces the time and labor required compared to traditional grinding methods.

Centerless Belt Grinder A Comprehensive Overview

The grinding process itself involves two primary types of abrasives belt and wheel. The combination of these abrasives allows for a smoother finish and enhances the lifespan of the grinding equipment. Additionally, the use of a belt grinder can significantly reduce the heat generated during the grinding process, minimizing the risk of workpiece distortion or damage.

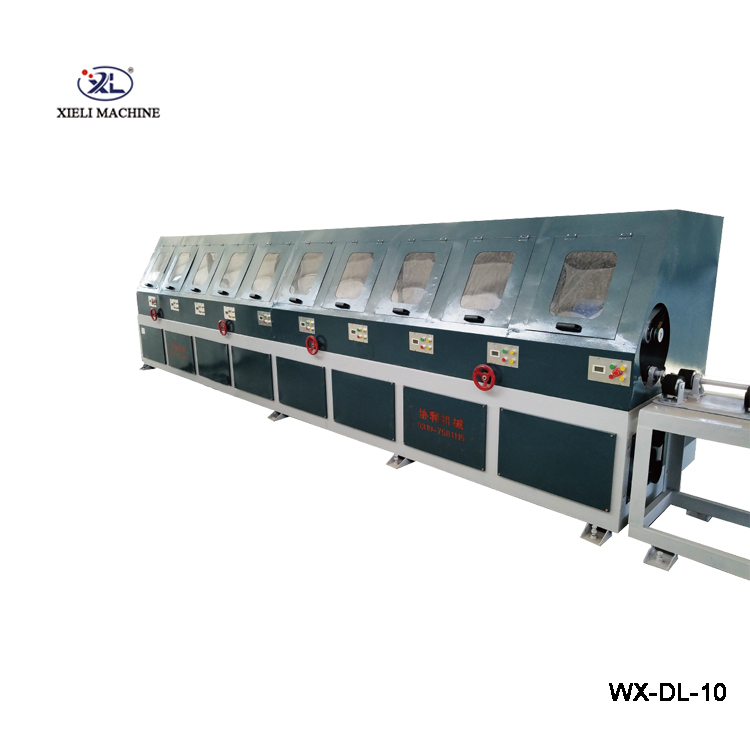

centerless belt grinder product

Another notable feature of centerless belt grinders is their adaptability. Many models allow for easy adjustments to accommodate different workpiece sizes and types, making them suitable for both batch production and one-off machining tasks. This flexibility is essential in today’s fast-paced manufacturing environment, where rapid changes in production demands are common.

When considering a centerless belt grinder, it is essential to evaluate factors like machine size, type of bearings, and the specific power requirements. High-quality components ensure longevity and reliability, thereby reducing downtime and maintenance costs. Furthermore, advanced models are equipped with automated features that optimize operational processes, such as automatic feeding and real-time monitoring, enhancing productivity even further.

The centerless belt grinder is a testament to modern engineering, combining speed, efficiency, and precision. As industries continue to evolve, the demand for such advanced tools will only increase, driving innovation in design and functionality. It stands as a cornerstone in the world of machining, proving indispensable for manufacturers striving to maintain competitive advantages while delivering top-notch products.

In conclusion, the centerless belt grinder is not merely a tool but an essential partner in industrial production. Its ability to deliver consistent results, coupled with its efficiency and versatility, makes it a favored choice among manufacturers. As technology advances, so too will the capabilities of these machines, paving the way for even greater advancements in manufacturing technologies.