The Rise of Stainless Steel Pipe Polishing Machines A Comprehensive Guide

Stainless steel pipes are an essential component in various industries, from construction and manufacturing to food processing and pharmaceuticals. Their durability, corrosion resistance, and aesthetic appeal make them the material of choice for a multitude of applications. However, for stainless steel pipes to perform optimally and maintain their visual appeal, they often require polishing. This is where stainless steel pipe polishing machines come into play. In this article, we will explore the significance of these machines, how they work, and the reasons why investing in one is a wise decision for businesses dealing with stainless steel pipes.

The Importance of Polishing Stainless Steel Pipes

Polishing stainless steel pipes serves multiple purposes. First and foremost, it enhances the appearance of the pipes, giving them a smooth, shiny finish that is visually appealing. This is particularly important in applications where aesthetics matter, such as in architectural projects or visible installations. Additionally, polishing removes surface imperfections, such as scratches and oxidation, which could compromise the integrity of the pipes over time.

Moreover, polished stainless steel pipes are easier to clean and maintain, making them ideal for industries that require high sanitary standards, such as food and beverage processing. A smooth surface minimizes the adherence of contaminants, thereby reducing the risk of contamination and ensuring compliance with health and safety regulations.

How Stainless Steel Pipe Polishing Machines Work

Stainless steel pipe polishing machines utilize a combination of mechanical and chemical processes to achieve the desired finish. The basic operation involves several steps

1. Preparation The pipes must be properly cleaned to remove any debris, grease, or previous coatings. This step is crucial for ensuring an even polish.

2. Grinding The first phase of polishing usually involves grinding the surface with specialized abrasive materials. This helps to effectively smooth out any rough spots and begin the leveling process.

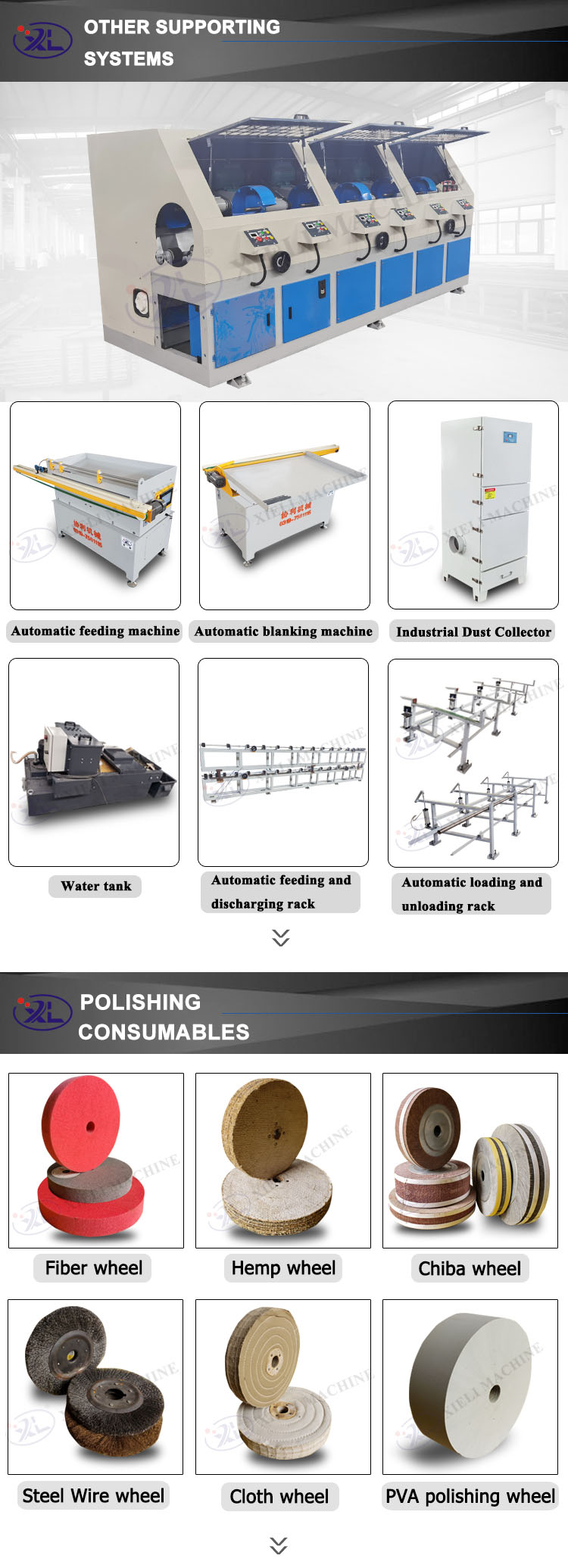

3. Polishing After grinding, the pipes are subjected to a polishing process, which often involves the use of polishing wheels and compounds. These can be made from various materials, including felt, cotton, or synthetic fibers, combined with polishing pastes that contain fine abrasive particles.

buy stainless steel pipe polishing machine

4. Buffing Finally, buffing is employed to give the pipes a high-gloss finish. This step is crucial for achieving that sleek, reflective surface that is characteristic of well-polished stainless steel.

Benefits of Investing in Pipe Polishing Machines

1. Increased Efficiency Manual polishing processes can be time-consuming and require significant labor. Investing in a stainless steel pipe polishing machine automates much of the work, significantly increasing throughput and allowing for more efficient production.

2. Consistent Quality Machine polishing ensures a uniform finish across all pipes, eliminating variations that may occur with manual techniques. This consistency is vital for companies looking to maintain a reputable brand image and meet customer expectations.

3. Cost Savings While the initial investment in a polishing machine may be substantial, the long-term savings from increased productivity, reduced labor costs, and minimized material waste can be significant. Additionally, the longer lifespan of polished pipes can lead to cost reductions over time.

4. Versatility Many modern stainless steel pipe polishing machines are designed to handle various pipe sizes and shapes, offering versatility to businesses that work with a range of products. This adaptability can help companies dodge significant equipment expenditures in the long run.

5. Improved Safety Polishing machines can help reduce workplace injuries associated with manual polishing methods. These machines often incorporate safety features that protect operators, making the work environment safer overall.

Conclusion

Stainless steel pipe polishing machines are invaluable assets for businesses involved in the production, maintenance, or installation of stainless steel pipes. By ensuring a high-quality finish, these machines enhance both the aesthetic and functional properties of pipes, leading to a long-lasting and appealing product. As industries continue to demand higher standards in both performance and appearance, investing in advanced polishing technology is not just wise; it’s essential for competitive success. If you’re considering upgrading or starting your polishing operations, exploring the range of available stainless steel pipe polishing machines is a significant first step toward achieving greater efficiency and quality.