The Benefits of Buying a Stainless Steel Mirror Polishing Machine

In the world of manufacturing and metalworking, the importance of surface finish cannot be overstated. An exquisite surface finish enhances the aesthetic appeal of a product and often reflects its overall quality. For businesses specializing in stainless steel products—from kitchen appliances to decorative items—a stainless steel mirror polishing machine is an indispensable tool. This article explores the advantages of investing in such a machine, the technology behind it, and practical tips for making an informed purchase.

What is a Stainless Steel Mirror Polishing Machine?

A stainless steel mirror polishing machine is engineered specifically for polishing and finishing stainless steel surfaces to achieve a high-gloss, mirror-like finish. These machines utilize various techniques, including mechanical polishing, chemical processes, and abrasive materials, to refine the surface of stainless steel components effectively. The end result is a smooth, reflective surface that not only enhances the aesthetic appeal of the product but also offers other functional benefits.

Benefits of Using a Stainless Steel Mirror Polishing Machine

1. Enhanced Appearance Products with a mirror finish are visually striking. The polished surfaces can reflect light beautifully, making them particularly popular in luxury items, decorative pieces, and high-end appliances. Investing in a polishing machine allows businesses to improve product attractiveness, which can significantly influence customer purchasing decisions.

2. Improved Corrosion Resistance Polished stainless steel is less prone to corrosion than its dull counterparts. The smooth surface minimizes the chances of moisture and contaminants adhering to the metal, which can lead to rust and tarnishing. This is especially important for products that will be exposed to harsh environments or require frequent cleaning.

3. Increased Durability The polishing process can help to close the microscopic pores on the steel surface, creating a stronger barrier against physical abrasion and chemical exposure. This durability is a vital consideration in sectors where performance and longevity are critical.

4. Efficient Production Automating the polishing process with a dedicated machine dramatically speeds up production times compared to manual polishing methods. Many modern machines are designed for high efficiency, allowing manufacturers to produce quality results consistently while reducing labor costs.

5. Versatile Applications Stainless steel mirror polishing machines are suitable for a variety of applications, from small-scale projects to large industrial runs. They can be used to polish parts for food and beverage processing equipment, medical devices, automotive components, and more.

buy stainless steel mirror polishing machine

Technologies in Modern Polishing Machines

Today's stainless steel mirror polishing machines incorporate advanced technologies to improve performance and usability. Some machines feature adjustable speed controls, enabling users to fine-tune the polishing process according to the specific requirements of various materials and product types. Others may come equipped with automated feed systems, which facilitate continuous operation and alleviate manual input, further enhancing productivity.

Additionally, many modern polishing machines employ environmentally friendly methods, such as using biodegradable polishing compounds. This is particularly beneficial for businesses aiming to meet sustainability goals while maintaining high production standards.

Tips for Buying a Stainless Steel Mirror Polishing Machine

When considering the purchase of a stainless steel mirror polishing machine, there are several factors to keep in mind

1. Assess Your Needs Determine the types of stainless steel products you will be polishing and the expected volume of production. This will help you choose a machine that aligns with your operational requirements.

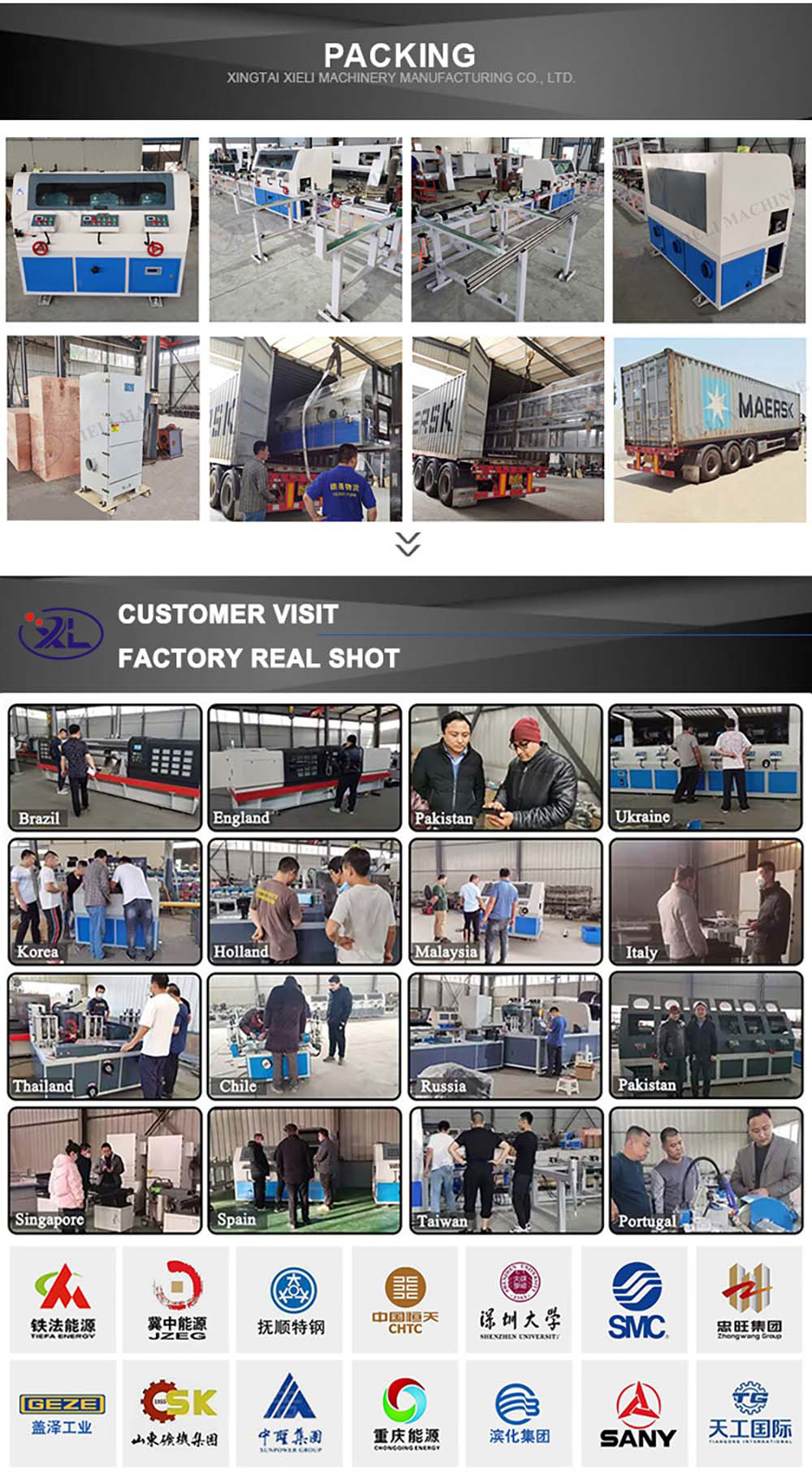

2. Research Brands and Models Not all polishing machines are created equal. Look for reputable manufacturers known for producing quality machinery with good after-sales support.

3. Consider Budget vs. Quality While it may be tempting to go for the cheapest option, investing in a high-quality machine can save you money in the long run through increased efficiency and reduced maintenance costs.

4. Read Reviews and Testimonials Feedback from other customers can provide valuable insights into the reliability and performance of specific machines, aiding you in your decision-making process.

In conclusion, purchasing a stainless steel mirror polishing machine is not just an investment in equipment; it is an investment in quality, efficiency, and reputation. By enhancing your products’ appearance and durability, you can set your business apart in a competitive marketplace. As you embark on this purchase, consider your specific needs, explore technologies available in the market, and choose wisely to ensure that your investment yields lasting benefits.