The Rise of Stainless Steel Polishing Machines in the Market

In the modern manufacturing landscape, the quest for efficiency, quality, and aesthetic appeal is ever-present. One notable trend that has garnered attention is the increasing demand for stainless steel polishing machines. Designed to enhance the finish of stainless steel surfaces, these machines play a crucial role in various industries, from automotive to food processing. This article delves into the significance of stainless steel polishing machines, their benefits, and factors to consider while buying one.

Importance of Stainless Steel Polishing

Stainless steel is revered for its durability, corrosion resistance, and shiny appearance. However, unpolished or poorly finished stainless steel can have visual flaws and may be susceptible to rust and tarnishing over time. Polishing not only elevates the aesthetic quality of stainless steel but also prepares surfaces for further treatments, such as coating or plating. In sectors such as food processing, a smooth surface is imperative for hygiene, as it minimizes the risk of bacterial growth.

Benefits of Using Stainless Steel Polishing Machines

1. Efficiency and Speed Manual polishing methods can be labor-intensive and time-consuming. Stainless steel polishing machines streamline the process, significantly reducing the time required to achieve a flawless finish. They can handle multiple pieces simultaneously, increasing production throughput.

2. Consistency and Quality Machines offer a level of consistency that is challenging to achieve manually. With adjustable settings, polishing machines can ensure that every piece has a uniform finish, minimizing the risk of human error.

3. Cost-Effectiveness Although the initial investment in polishing machinery can be significant, the long-term benefits often outweigh the costs. Reduced labor hours, minimized material wastage, and enhanced product quality contribute to a better return on investment.

4. Versatility Modern polishing machines can be adapted for different grades and types of stainless steel. They can handle various shapes and sizes, making them suitable for diverse applications across industries.

5. Safety Automated polishing reduces the exposure of workers to potentially harmful dust and particles that arise from manual polishing. This not only improves workplace safety but also enhances worker satisfaction and productivity.

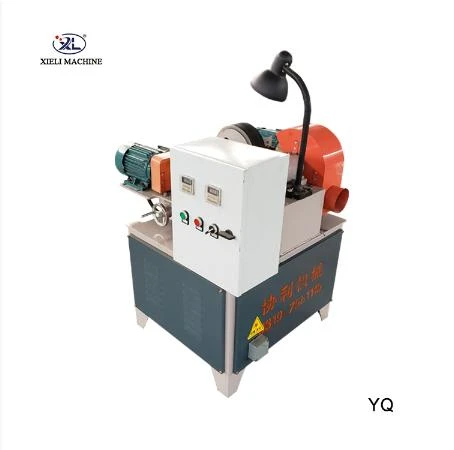

buy stainless polishing machine

What to Consider When Buying a Stainless Steel Polishing Machine

When it comes to investing in a stainless steel polishing machine, there are several factors to consider

1. Type of Machine There are different types of polishing machines, including belt polishers, disc polishers, and rotary polishers. Each type has specific applications, so it’s essential to choose one that aligns with your needs.

2. Power and Performance Evaluate the machine’s motor power and performance specifications. A robust machine will handle heavy workloads more efficiently and provide better finishes.

3. Ease of Use Look for a machine that is user-friendly and comes with clear instructions. Training staff on new equipment should be straightforward to ensure optimal operation.

4. Maintenance and Support Consider the maintenance requirements and the availability of technical support from the manufacturer. Reliable service and readily available replacement parts are critical for minimizing downtime.

5. Budget Finally, the budget is a crucial factor. Set a clear budget that includes not only the purchase price but also potential operating and maintenance costs over the life of the machine.

Conclusion

The stainless steel polishing machine is an invaluable asset for businesses striving to enhance their productivity and product quality. As industries continue to evolve and prioritize efficiency, investing in high-quality polishing machinery will undoubtedly pay dividends. With the right machine in place, manufacturers can achieve superior finishes that meet the stringent standards of today’s market, ensuring long-lasting and aesthetically pleasing stainless steel products.