Exploring the Benefits of Buying a DIY Centerless Grinder

In the world of metalworking and machining, precise and efficient grinding is essential for achieving high-quality finishes and tight tolerances. One of the most popular ways to improve grinding operations is through the use of a centerless grinder. For those who are passionate about DIY projects or in need of specific grinding capabilities, purchasing a DIY centerless grinder can be a game changer. In this article, we will explore the benefits of investing in your own centerless grinder, particularly for DIY enthusiasts.

What is a Centerless Grinder?

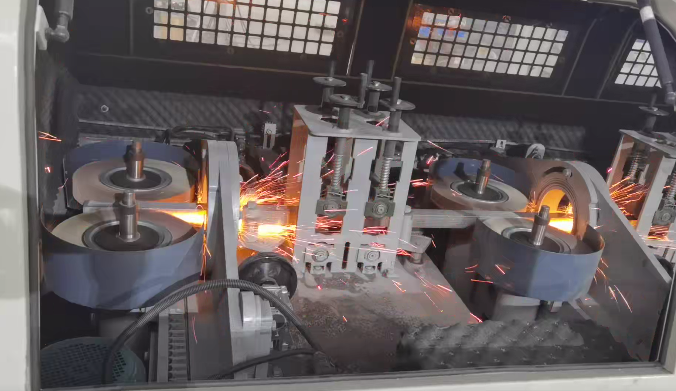

A centerless grinder is a type of grinding machine that removes material from a workpiece without the need for centering it in a chuck or fixture. This method is highly efficient because it allows for continuous operation and the ability to grind multiple parts simultaneously. The most significant advantage of centerless grinding is its ability to produce high-volume, highly accurate workpieces, making it a popular choice in manufacturing settings.

Why Consider a DIY Approach?

1. Cost-Effectiveness One of the primary reasons to consider a DIY centerless grinder is the cost savings. Commercial machines can be quite expensive, often running into the thousands of dollars. Building your own allows you to control the budget and select components that fit your financial constraints. With the right plans and resources, DIY enthusiasts can create a high-quality machine at a fraction of the price.

2. Customization Every grinding project is unique, and a DIY centerless grinder can be tailored to meet specific needs. For instance, you might want to adjust the size and geometry of the machine to suit particular workpieces or change the grinding wheel dimensions for different materials. Customizing your grinder ensures it performs optimally for your specific applications.

buy diy centerless grinder

3. Enhanced Learning Experience Building your own centerless grinder is an excellent opportunity to expand your knowledge of machining and grinding processes. It involves not only mechanical skills but also a deep understanding of materials and engineering principles. Engaging in such a project can enhance your skills and confidence in metalworking.

4. Sourcing Quality Parts When you take a DIY approach, you can select high-quality components from reputable sources. This allows you to ensure that your grinder is built with durable and efficient parts, which can improve performance and longevity. Researching and sourcing your materials is part of the enjoyable challenge that comes with DIY projects.

5. Technical Support and Community Resources The DIY community is vast and vibrant, with many resources available for those looking to build their machines. Online forums, tutorial videos, and blueprints can provide valuable guidance as you embark on your project. Additionally, you can connect with other DIY enthusiasts who may share their tips and experiences, helping you troubleshoot issues that may arise during the build.

Challenges

While there are numerous benefits to constructing your own centerless grinder, it’s important to acknowledge that challenges may arise. The complexity of design, potential for machine misalignment, and the need for precision can be daunting for some. However, with determination and research, these challenges can be overcome.

Conclusion

In summary, investing in a DIY centerless grinder can be a rewarding endeavor for metalworking enthusiasts. The cost-effectiveness, customization options, and educational benefits make building your own grinder an attractive choice. While challenges may exist, the learning experience and satisfaction of creating a functional piece of machinery can be incredibly fulfilling. As you explore the possibilities of a DIY centerless grinder, you’re not just building a machine – you’re honing your skills and embracing the creative potential of metalworking. Whether it’s for personal projects or small-scale production, a DIY centerless grinder can be a worthwhile investment that pays off in both performance and satisfaction.