Exploring the Best Through-Feed Centerless Grinders Efficiency and Precision in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One machine that embodies these qualities is the through-feed centerless grinder. This specialized tool is designed to grind surfaces and shapes with exceptional accuracy, making it a favorite among manufacturers who need to produce high volumes of materials with consistent quality. In this article, we will explore what makes the best through-feed centerless grinders stand out, their applications, and the advantages they bring to the manufacturing process.

Understanding Through-Feed Centerless Grinding

Centerless grinding differs from traditional grinding methods in that it does not require the workpiece to be clamped in place. Instead, the component rests on a rotating platform, and the grinding wheel rotates against it while a regulating wheel controls the speed and feed rate. This method allows for continuous and efficient processing of long, slender workpieces, making it ideal for mass production.

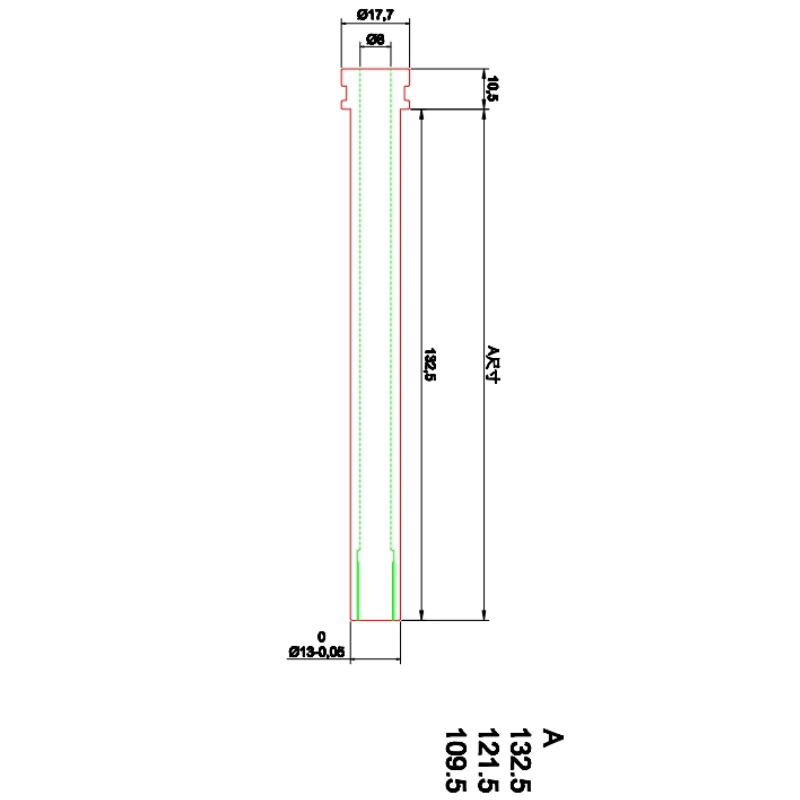

Through-feed centerless grinders are particularly well-suited for cylindrical parts that need to be ground in long lengths, such as rods and tubes. The parts enter one end of the grinder and exit the other end as finished products, facilitating high throughput rates.

Key Features of the Best Centerless Grinders

1. Precision Engineering The most effective through-feed centerless grinders are built to endure the rigors of continuous operation while maintaining precision. They offer finely adjustable parameters that allow operators to achieve the exact tolerances required for each application.

2. Robust Construction Durability is essential in a high-precision machine tool. Top-tier centerless grinders are constructed from high-quality materials and are often designed with reinforced frames and robust components to withstand wear over time.

3. User-Friendly Controls Modern grinders come equipped with advanced control systems that simplify operation. User-friendly interfaces allow operators to easily adjust settings, monitor performance, and optimize grinding processes for various materials and shapes.

4. Versatility The best through-feed centerless grinders can accommodate a variety of workpiece sizes, shapes, and materials. This versatility makes them valuable in different manufacturing sectors, from automotive and aerospace to electronics and medical device production.

5. Automated Features Automation is becoming increasingly important in manufacturing. High-quality centerless grinders often incorporate automated loading and unloading systems, reducing labor requirements and increasing overall efficiency.

Advantages of Through-Feed Centerless Grinding

best thru feed centerless grinder

The advantages of using the best through-feed centerless grinders are numerous. Here are some key benefits

- High Production Rates The continuous process minimizes downtime and accelerates production, making it possible to process thousands of parts in a relatively short period.

- Consistent Quality By eliminating the need for workpiece clamping, through-feed centerless grinding maintains consistent pressure and alignment, producing parts with uniform dimensions and surface finishes.

- Cost-Effectiveness Although initial investments in high-quality grinders can be significant, the long-term savings on labor, material waste, and energy consumption often outweigh these costs.

- Reduced Setup Time Through-feed centerless grinders typically require less setup time compared to traditional grinding methods, meaning less time is spent preparing the machine and more time is dedicated to production.

Applications of Through-Feed Centerless Grinders

Through-feed centerless grinders find applications in various industries. Common uses include

- Automotive Parts Production Components like transmission shafts, valve stems, and steering columns often require centerless grinding to achieve precise tolerances.

- Aerospace Components Aerospace parts demand the highest quality standards, making the precision of centerless grinders essential for producing components such as landing gear and turbine shafts.

- Medical Devices The medical field relies on precision-manufactured parts, where centerless grinding plays a crucial role in creating instruments and devices that meet strict regulatory requirements.

Conclusion

Through-feed centerless grinders are indispensable tools in modern manufacturing, offering unmatched efficiency, precision, and versatility. Selecting the best machine depends on your specific needs, but investing in quality through-feed centerless grinders will undoubtedly enhance your production capabilities and contribute to your business's success. Whether you're in aerospace, automotive, or any other industry that requires precision-engineered components, embracing this technology can lead to significant advancements in your manufacturing processes.